Magnetic solid acid and preparation method thereof

A magnetic solid acid and magnetic technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as difficult large-scale production and commercial application, complex chemical reaction process, expensive raw materials, etc. , to achieve the effects of easy large-scale production, broad application prospects, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

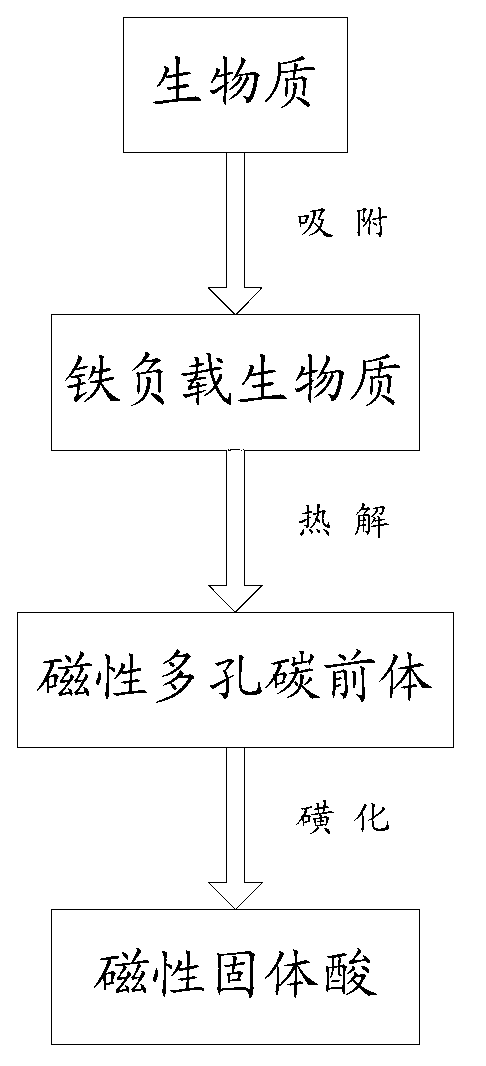

[0029] The invention provides a preparation method of magnetic solid acid, such as figure 1 shown, including the following steps:

[0030] Step 1: Adsorb iron ions on lignocellulosic biomass to obtain iron-loaded biomass, in which iron ions can be ferrous iron or ferric iron, and lignocellulosic biomass can include straw or trees or sawdust or sawdust And many other options. The adsorption method can adopt methods well known to those skilled in the art, preferably as follows: add lignocellulosic biomass to the solution containing iron ions, heat and stir the mixed solution, then carry out solid-liquid separation treatment on the mixed solution and The obtained solid is dried to obtain the iron-loaded biomass. The solid-liquid separation treatment of the mixed solution and the drying of the obtained solid are for the convenience of the subsequent pyrolysis process, and can also ensure that bio-oil can be obtained during the pyrolysis process. In addition, solid-liquid separat...

Embodiment 1

[0040] (1) Weigh 2.70g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Dissolve in 100mL deionized water to obtain a 0.1mol / L ferric chloride solution, then weigh 10g of waste sawdust biomass, add it to the prepared ferric chloride solution, place it in a water bath magnetic stirrer, and put the The temperature was raised to 50°C, stirred at a speed of 300r / min for 180min, and then the water was distilled off under reduced pressure by a rotary evaporator, and the obtained solid was dried in an oven to obtain iron-loaded biomass;

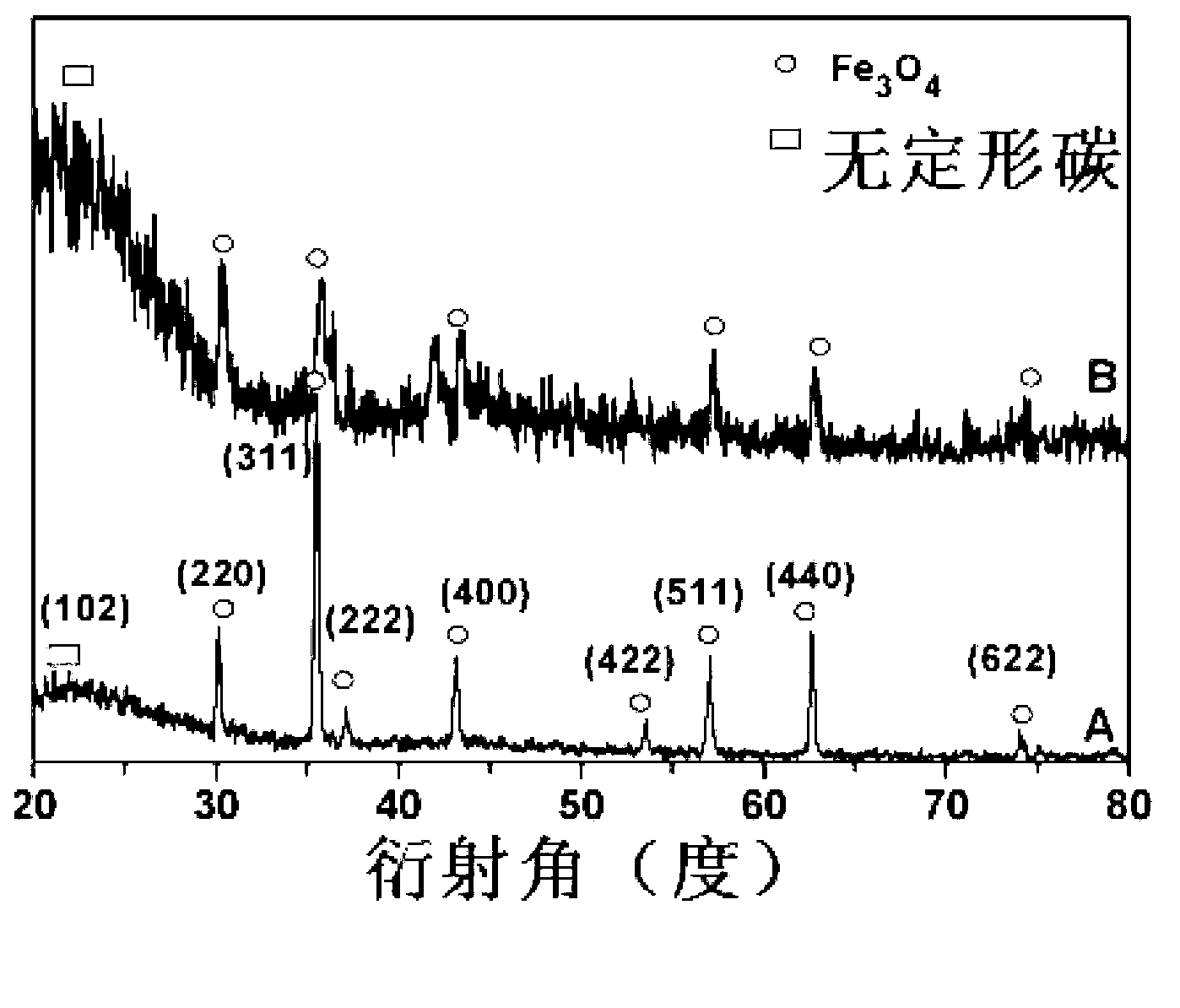

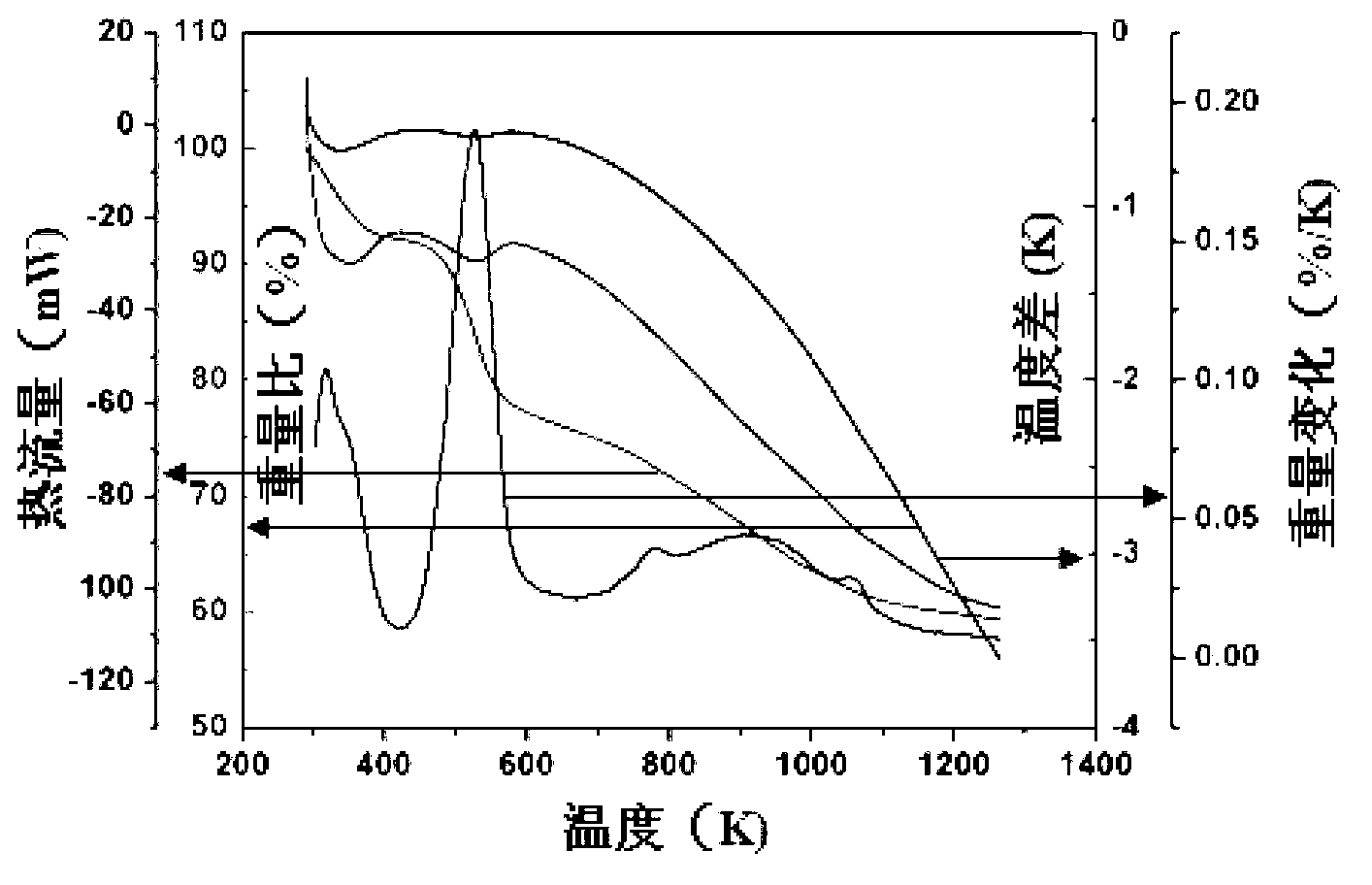

[0041] (2) Pyrolyze the iron-loaded biomass obtained in step (2) at 500°C under a nitrogen atmosphere for 1 hour to obtain a magnetic porous carbon precursor, and at the same time, bio-oil resources can also be obtained;

[0042] (3) Weigh 3 grams of magnetic porous carbon precursor and place it in a long-necked flask, add 30 mL of concentrated sulfuric acid, react at 150 °C for 12 hours, then pour the reaction mixture into 1000 mL of water, and then f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Acid strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com