High temperature resisting nanoscale sulfoselenide cadmium paint and preparation method thereof

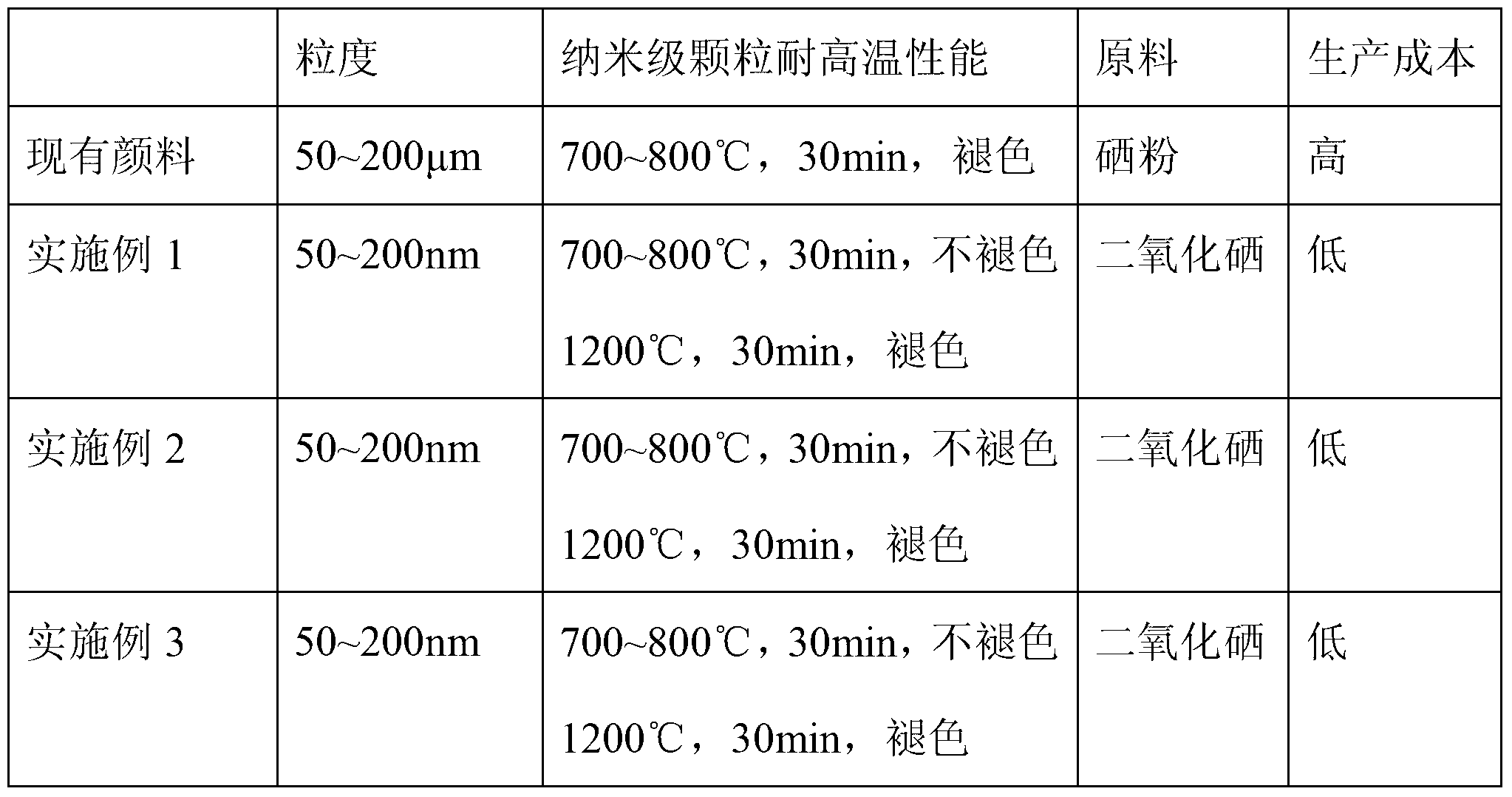

A nano-scale technology of cadmium sulfur selenide, applied in the field of pigments, can solve problems such as limitations, and achieve low cost, excellent effect, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

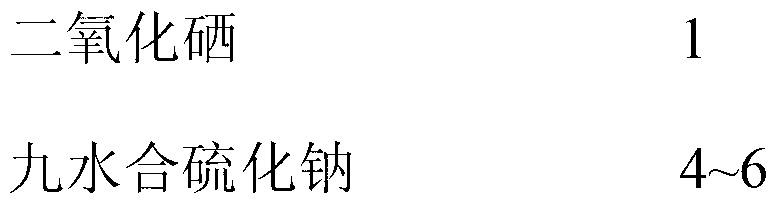

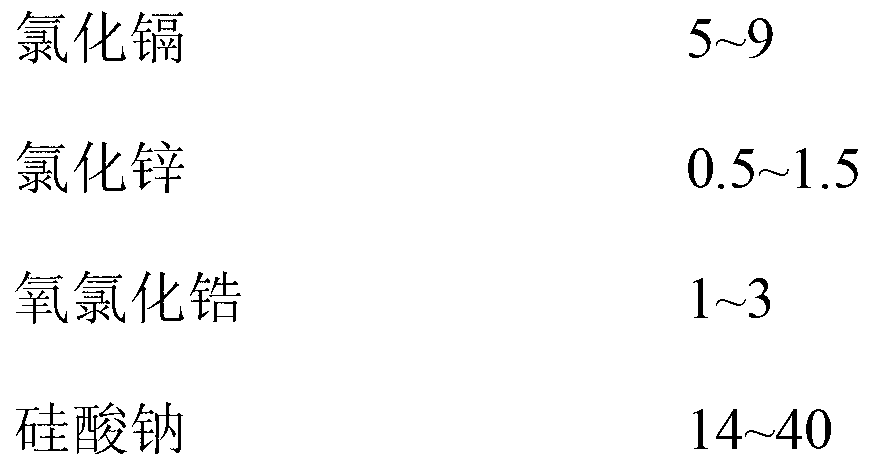

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of precursor:

[0041] (1a) 384.6g sodium sulfide nonahydrate (Na 2 S·9H 2 O) was dissolved in 4.8L water to make sodium sulfide solution, and 32g selenium dioxide (SeO 2 ) into the above sodium sulfide solution, fully dissolved under the action of ultrasonic waves.

[0042] (1b) 435.9g cadmium chloride (CdCl 2 ) was dissolved in 6.4L of water to prepare a cadmium chloride solution, and poured into the solution obtained in step (1a), and stirred for 1 h with a magnetic stirrer at a speed of 200 r / min.

[0043] (1c) 25.6g zinc chloride (ZnCl 2 ) was dissolved in 2.6L water to form a zinc chloride solution, and 112.2g zirconium oxychloride (ZrOCl 2 ) was dissolved in 3.2L of water to prepare a zirconium oxychloride solution, and the above-mentioned zinc chloride solution and zirconium oxychloride solution were poured into the solution obtained in step (1b), and stirred evenly.

[0044] (1d) 1275.6g sodium silicate (Na 2 SiO 3 ) was dissolved in 6.4...

Embodiment 2

[0054] (1) Preparation of precursor:

[0055] (1a) 278.6g sodium sulfide nonahydrate (Na 2 S·9H 2 O) was dissolved in 4.8L water to make sodium sulfide solution, and 32g selenium dioxide (SeO 2 ) into the above sodium sulfide solution, fully dissolved under the action of ultrasonic waves.

[0056] (1b) 478.5g cadmium chloride (CdCl 2 ) was dissolved in 6.4L of water to prepare a cadmium chloride solution, and poured into the solution obtained in step (1a), and stirred for 1 h with a magnetic stirrer at a speed of 200 r / min.

[0057] (1c) 59.3g zinc chloride (ZnCl 2 ) was dissolved in 2.6L water to form a zinc chloride solution, and 155.1g zirconium oxychloride (ZrOCl 2 ) was dissolved in 3.2L of water to prepare a zirconium oxychloride solution, and the above-mentioned zinc chloride solution and zirconium oxychloride solution were poured into the solution obtained in step (1b), and stirred evenly.

[0058] (1d) 495.6g of sodium silicate (Na 2 SiO 3 ) was dissolved in 6...

Embodiment 3

[0068] (1) Preparation of precursor:

[0069] (1a) 417.9g sodium sulfide nonahydrate (Na 2 S·9H 2 O) was dissolved in 4.8L water to make sodium sulfide solution, and 32g selenium dioxide (SeO 2 ) into the above sodium sulfide solution, fully dissolved under the action of ultrasonic waves.

[0070] (1b) 265.8g cadmium chloride (CdCl 2 ) was dissolved in 6.4L of water to prepare a cadmium chloride solution, and poured into the solution obtained in step (1a), and stirred for 1 h with a magnetic stirrer at a speed of 200 r / min.

[0071] (1c) 19.8g zinc chloride (ZnCl 2 ) was dissolved in 2.6L water to form a zinc chloride solution, and 51.7g zirconium oxychloride (ZrOCl 2 ) was dissolved in 3.2L of water to prepare a zirconium oxychloride solution, and the above-mentioned zinc chloride solution and zirconium oxychloride solution were poured into the solution obtained in step (1b), and stirred evenly.

[0072] (1d) 1415.9g sodium silicate (Na 2 SiO 3 ) was dissolved in 6.4L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com