Method and device for synthesizing plasticizer by regulating pressure

A technology for adjusting pressure and plasticizers, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of short reaction time, long time-consuming synthesis process, high energy consumption, etc., achieve color improvement and save energy Effects that consume and increase the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

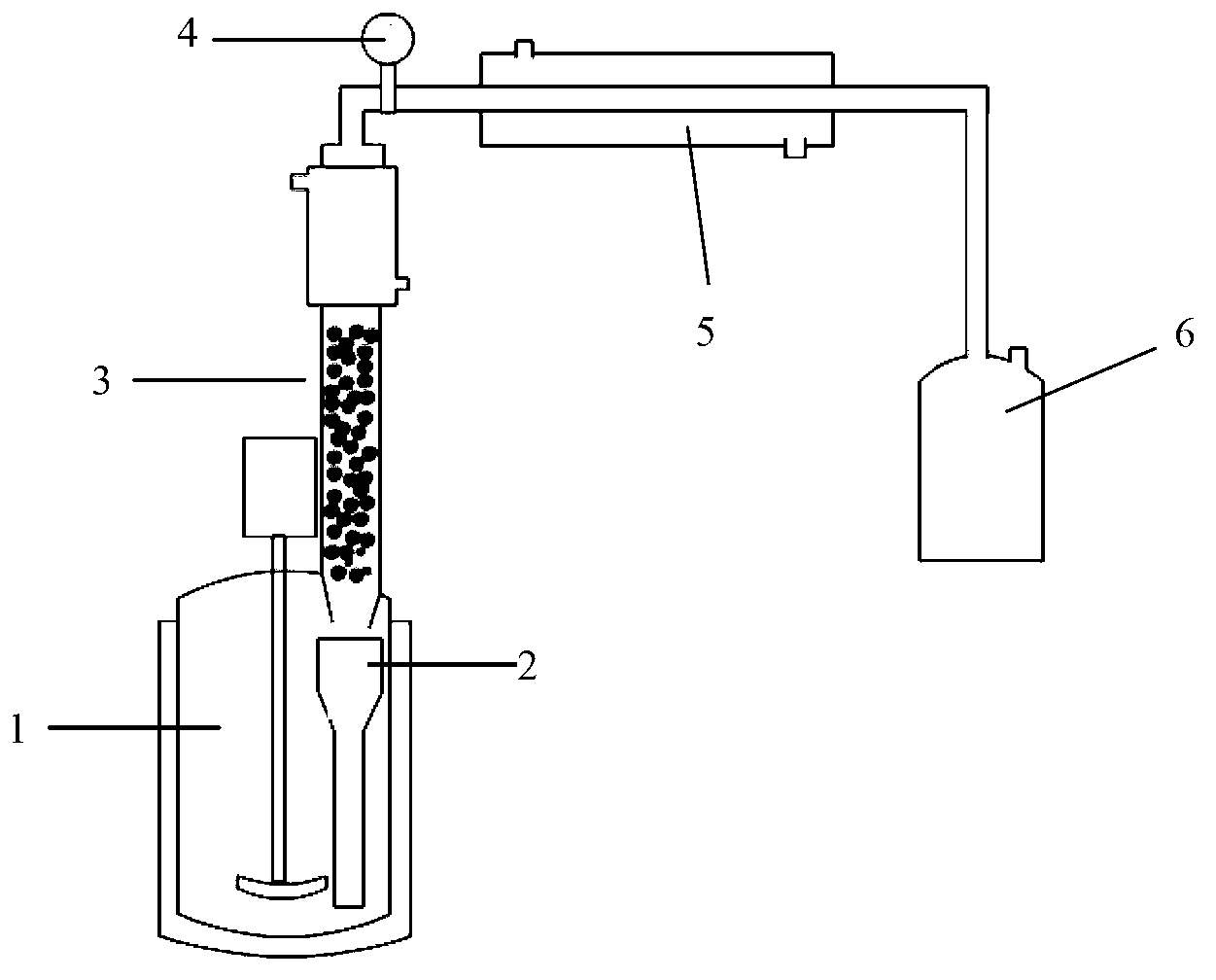

[0024] A device for adjusting pressure to synthesize a plasticizer, including a pressure-resistant kettle 1, a funnel line 2, a rectification tower 3, a pressure relief valve 4, a condenser 5 and a recovery tank 6, and the rectification tower 3 is located in the pressure-resistant kettle 1 The upper part of the funnel pipeline 2 is arranged in the pressure-resistant kettle 1, the outlet at the bottom of the rectification tower 3 is opposite to the upper inlet of the funnel pipeline 2, the upper part of the rectification tower 3 is connected with the recovery tank 6 through the condenser 5, and the pressure relief valve 4 It is arranged on the connecting pipeline between the rectification column 3 and the condenser 5. There is a gap between the bottom outlet of the rectification tower and the upper inlet of the funnel pipeline.

[0025] Raw materials: terephthalic acid, isooctyl alcohol, catalyst tetrabutyl titanate;

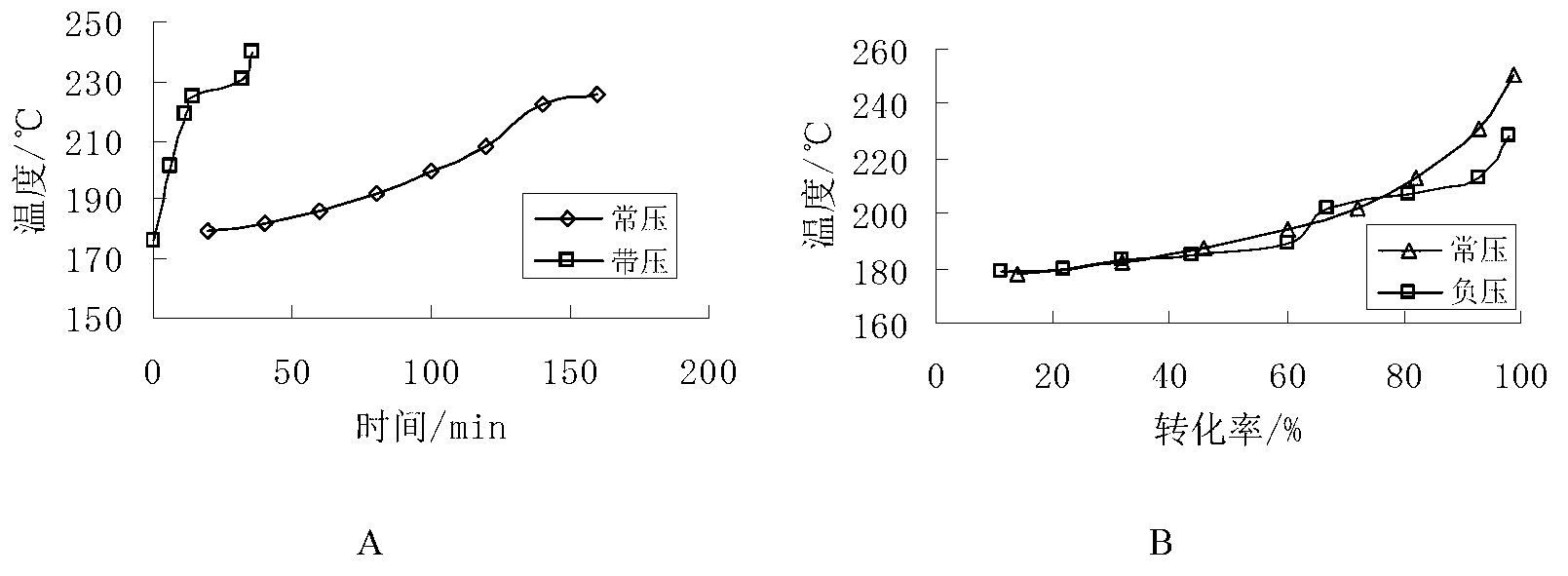

[0026] Put isooctyl alcohol and terephthalic acid with an ...

Embodiment 2

[0028] Raw materials: pool material PTA, isooctyl alcohol, catalyst isopropyl titanate, antioxidant sodium hypophosphite; the device is the same as in Example 1.

[0029] Put isooctyl alcohol with an alkyd molar ratio of 3.2:1 and pool material PTA into an autoclave, heat to 150°C for dehydration, then add 0.15%wt of isopropyl titanate and 0.1%wt of sodium hypophosphite to the reaction system Heating and stirring, pressurized reaction, when the temperature reaches 220°C and the pressure reaches 0.3MPa, the pressure control device will automatically exhaust the pressure and discharge the water generated in the reaction to the recovery tank, maintain the pressure at 0.25MPa, and release it after 1 hour of reaction Pressure to normal pressure reaction, the temperature rises again to 210°C within 2 to 3 hours, and gradually vacuums to -0.01MPa within 1 to 2 hours, and the pressure reaction can be stopped when the acid value is less than 1mgKOH / g. During the process, gaseous isooct...

Embodiment 3

[0031] Raw materials: ground material PTA, isooctyl alcohol, catalyst dibutyltin p-toluenesulfonate; the device is the same as in Example 1.

[0032] Put isooctyl alcohol with an alkyd molar ratio of 3:1 and the ground material terephthalic acid into an autoclave, heat to 160°C for dehydration, then add dibutyltin di-p-toluenesulfonate accounting for 0.3%wt of the reaction system, heat and stir, Pressurized reaction, when the temperature reaches 240°C and the pressure reaches 0.4MPa, the pressure control device automatically exhausts the pressure and discharges the water generated in the reaction to the recovery tank to maintain the pressure at 0.3MPa. After 1.5 hours of reaction, release the pressure to normal pressure for reaction, and the temperature rises to 200°C again within 2 to 3 hours, and gradually vacuum to -0.03MPa within 1 to 2 hours. When the acid value is less than 1mgKOH / g, the belt can be stopped. Pressure reaction, gaseous isooctyl alcohol is refluxed through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com