Method for pretreating lignocellulose raw material by pyrolysis

A lignocellulose and pretreatment technology, which is applied in the fields of biomass pretreatment, biomass post-treatment, biochemical equipment and methods, etc., to achieve the effects of short time consumption, improved conversion rate and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

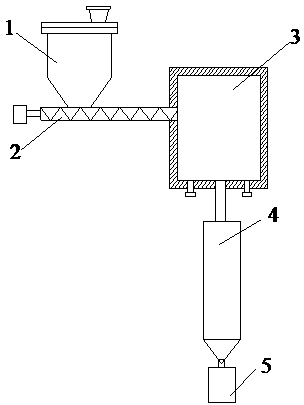

Method used

Image

Examples

Embodiment 1

[0020] Set the temperature of the pyrolyzer to 200°C, and feed the hot carrier gas with oxygen-deficient combustible gas under normal pressure. The treated corn stalks (moisture content 8.7%, volatile solids 76.45%, cellulose 34.31%, semi-fiber 26.82% lignin, 16.18% lignin, particle size 0.1-1mm) into the material box, the raw material enters the reactor through an adjustable speed feeder, and the residence time of the raw material in the reactor is 1s. The temperature in the reactor is measured by a thermocouple, and the temperature control device monitors it in real time. After the raw material is heated rapidly, it enters the separator, and the processed raw material is separated through the separator and collected into the material box. Then, the treated corn stalks were measured with Italian WELP FIWE6 cellulose measuring instrument, referring to the Paradigm Washing Fiber Method, for the determination of cellulose, hemicellulose and lignin. The measurement results showe...

Embodiment 2

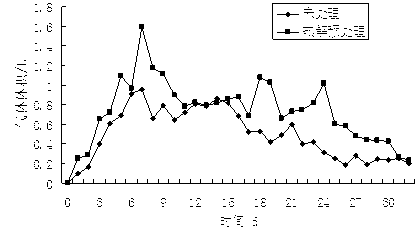

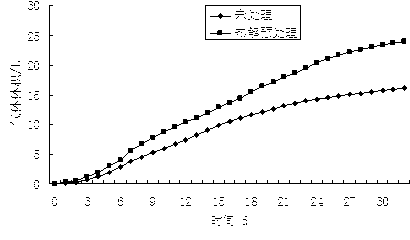

[0022] Set the temperature of the pyrolyzer to 200°C, and feed the hot carrier gas with oxygen-deficient combustible gas under normal pressure. The treated corn stalks (moisture content 8.7%, volatile solids 76.45%, cellulose 34.31%, semi-fiber 26.82% lignin, 16.18% lignin, particle size 0.1-1mm) into the material box, the raw material enters the reactor through an adjustable speed feeder, and the residence time of the raw material in the reactor is 1s. The temperature in the reactor is measured by a thermocouple, and the temperature control device monitors it in real time. After the raw material is heated rapidly, it enters the separator, and the processed raw material is separated through the separator and collected into the material box. Then 118g of corn stalks pretreated by pyrolysis were taken for anaerobic fermentation test. The test adopts liquid fermentation, the concentration of fermentation feed liquid is 8.5%, the concentration of inoculum is 30%, and the organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com