Device and method for quenching dry-method treatment and sensible heat recovery of high-temperature molten slag

A waste heat recovery device and slag technology, which are applied in waste heat treatment, energy efficiency improvement, lighting and heating equipment, etc., can solve the problems of complex structure of granulation device, distance for industrial application, and reliability to be improved, etc. Industrialized production, good application prospects, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

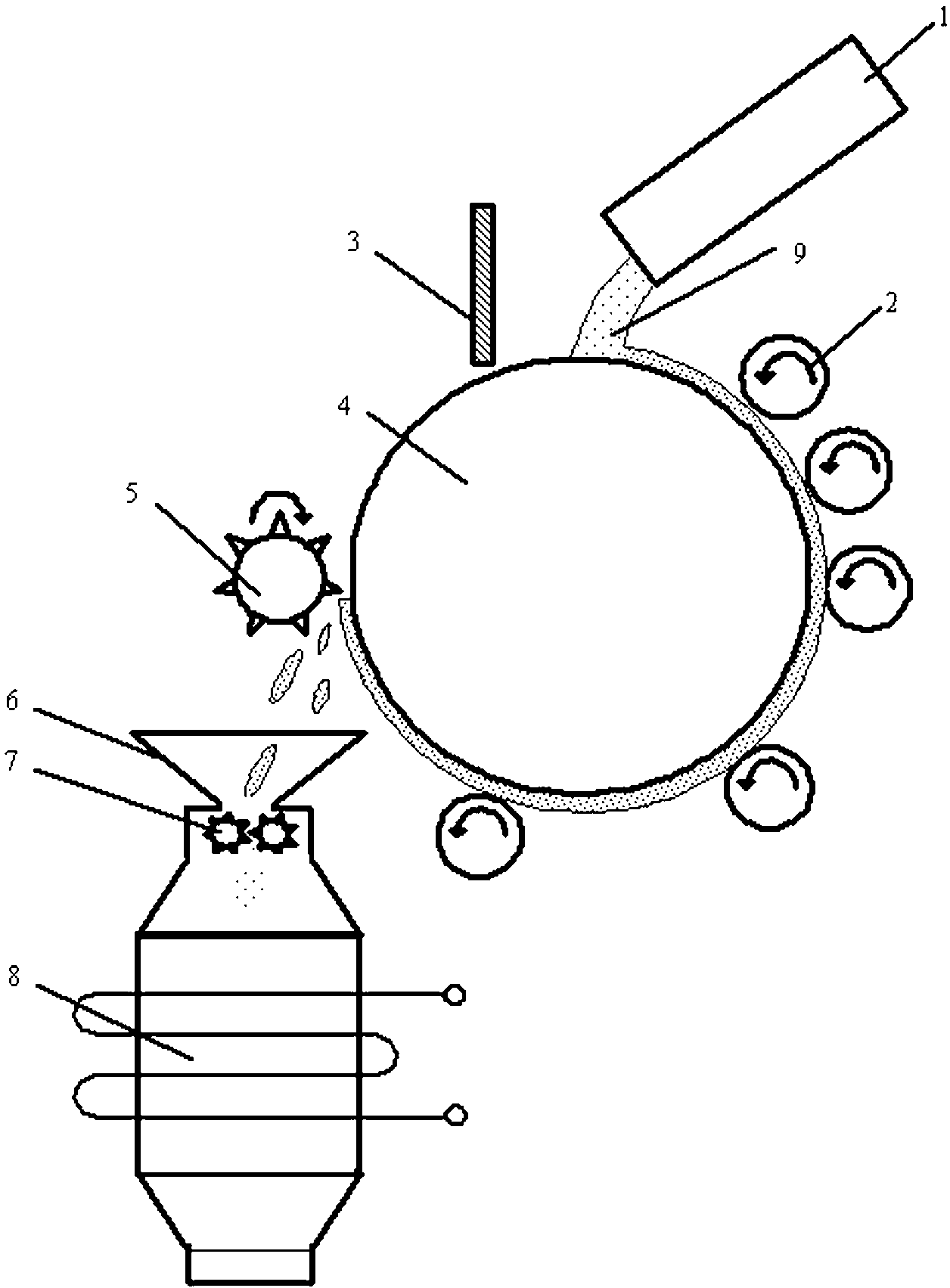

[0037] The structure of the device for rapid cooling and dry treatment of high-temperature slag and recovery of sensible heat is as follows: figure 1 As shown, it includes slag guide groove 1, slag retaining plate 3, drum 4, cooling roller group, slag removal roller 5, slag particle collector 6 and waste heat recovery device 8; slag retaining plate 3, slag guide groove 1, cooling roller The group and slag removal rollers 5 are arranged in turn on the outer surface of the drum 4 along the rotation direction of the drum 4. The slag guide groove 1 and the slag retaining plate 3 are respectively located on both sides above the top of the drum 4. The slag removal roller 5 and the slag retaining plate There is a gap between 3 and the drum 4, the distance between the cooling roller group and the outer surface of the drum 4 is 5mm, the distance between the slag guide groove 1 and the outer surface of the drum 4 is 100mm; There is a slag particle collector 6, a crusher 7 is provided at...

Embodiment 2

[0052] The structure of the high-temperature molten slag quenching dry process and recovery of sensible heat is the same as that of Example 1, the difference is that:

[0053] (1) The waste heat recovery device is a fixed bed, and the cooling medium is air;

[0054] (2) The cooling roll group consists of 4 water-cooled rolls;

[0055] (3) The distance between the cooling roller group and the outer surface of the drum is 30mm;

[0056] (4) The distance between the slag guide groove and the outer surface of the drum is 400mm;

[0057] The method of high-temperature molten slag quick-cooling dry process and recovery sensible heat is the same as embodiment 1, and the difference is:

[0058] (1) Granular slag is formed after being pulverized into the fixed bed, and normal temperature air is passed into the fixed bed to exchange heat with the granular slag, forming hot air to absorb heat, and the granular slag is discharged after waste heat recovery; 8.1x10 5 m 3 / h;

[0059]...

Embodiment 3

[0064] The structure of the high-temperature molten slag quenching dry process and recovery of sensible heat is the same as that of Example 1, the difference is that:

[0065] (1) The waste heat recovery device is a fixed bed, and the cooling medium is air;

[0066] (2) The cooling roll group consists of 12 water-cooled rolls;

[0067] (3) The distance between the cooling roller group and the outer surface of the drum is 60mm;

[0068] (4) The distance between the slag guide groove and the outer surface of the drum is 800mm;

[0069] The method of high-temperature molten slag quick-cooling dry process and recovery sensible heat is the same as embodiment 1, and the difference is:

[0070] (1) Granular slag is formed into the fluidized bed after being pulverized, and normal temperature air is passed into the fluidized bed to exchange heat with the granular slag, forming hot air to absorb heat, and the granular slag is discharged after waste heat recovery; The input amount is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com