Ultra-high toughness, excellent weldability ht550 steel plate and manufacturing method thereof

A technology with ultra-high toughness and weldability, applied in manufacturing tools, furnace types, quenching agents, etc., can solve problems such as high steel plate manufacturing costs, reduced welding efficiency, and deterioration of the working environment at the welding site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with embodiments and drawings.

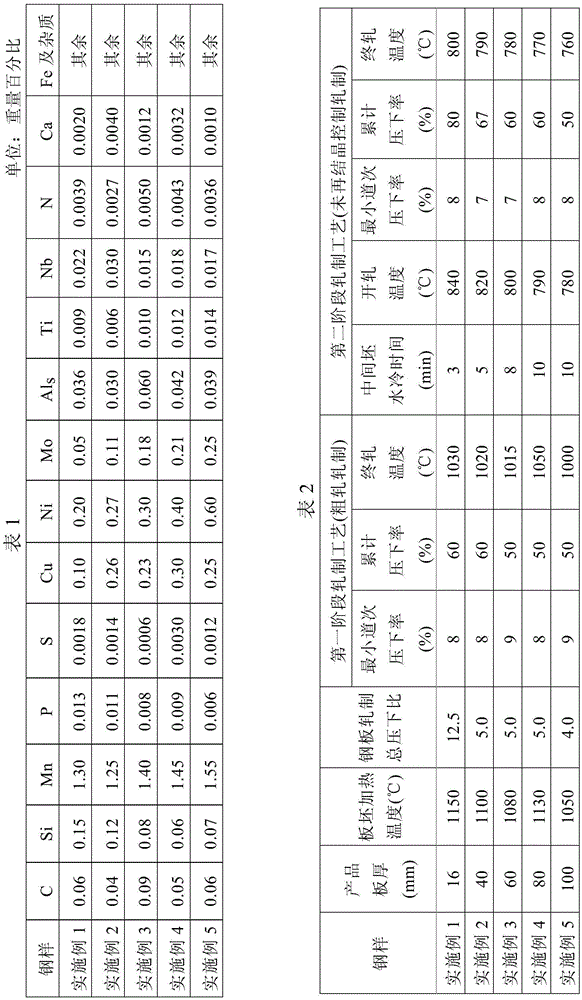

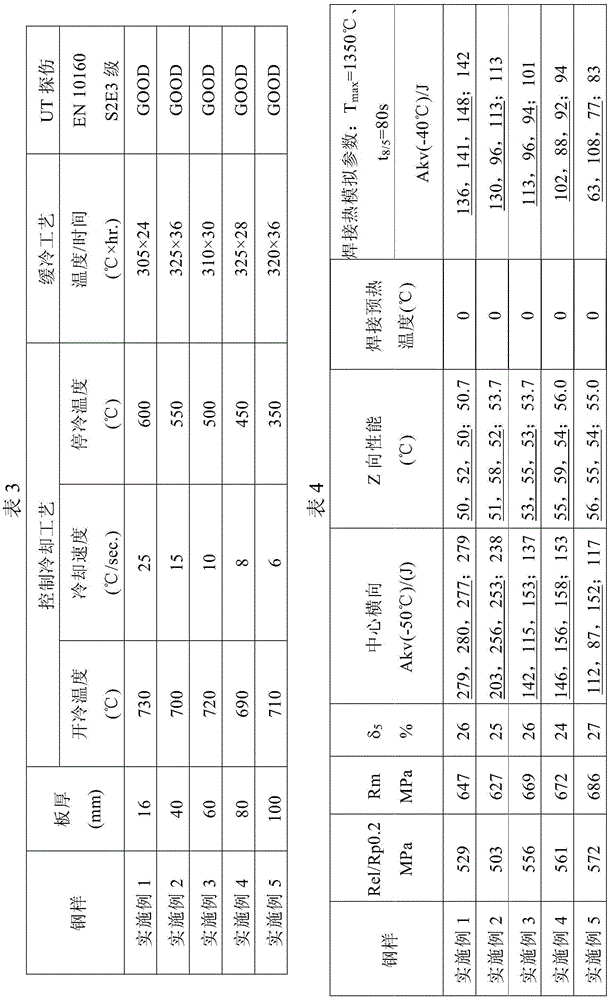

[0056] See Table 1 for the composition of the example steel of the present invention, and refer to Table 2 and Table 3 for the manufacturing process of the example steel. Table 4 shows the properties of the example steel of the present invention.

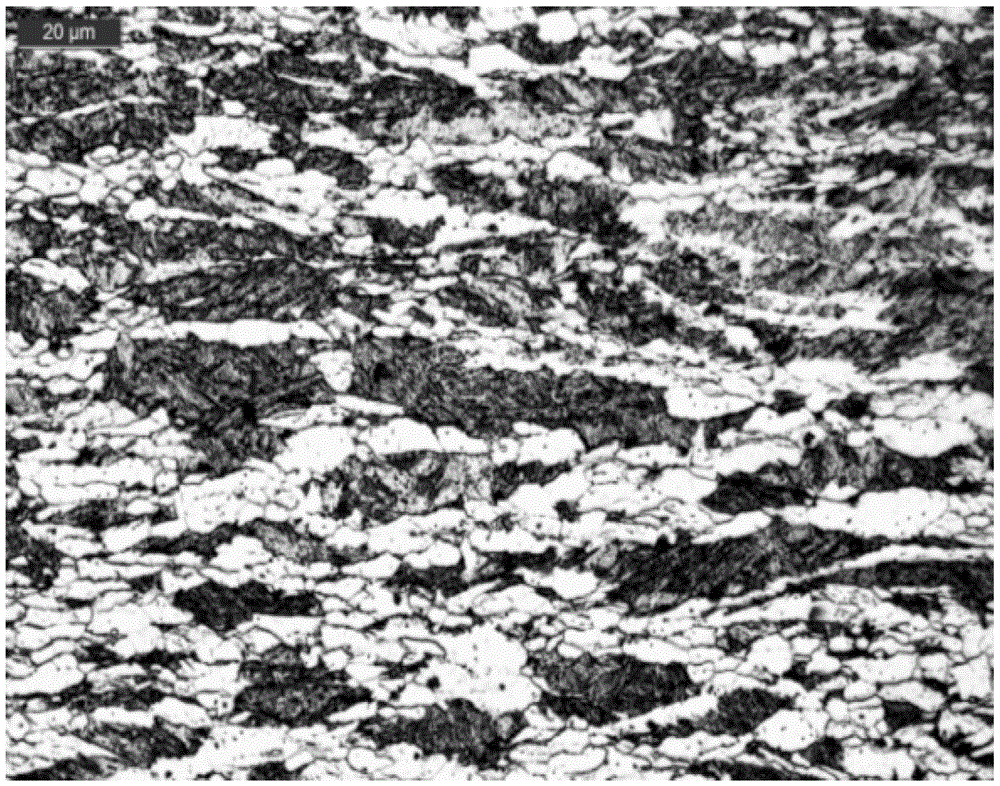

[0057] Such as figure 1 As shown, the final microstructure of the steel sheet of the present invention is fine ferrite + self-tempered bainite, and the average grain size is below 15 μm.

[0058] The steel plate of the present invention not only produces TMCP steel plate with excellent comprehensive performance at low cost through simple component combination design and combination with TMCP manufacturing process, but also greatly shortens the steel plate manufacturing cycle, creates huge value for the enterprise, and realizes Green manufacturing process. The high performance and high added value of the steel plate are concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com