Air gap forming method

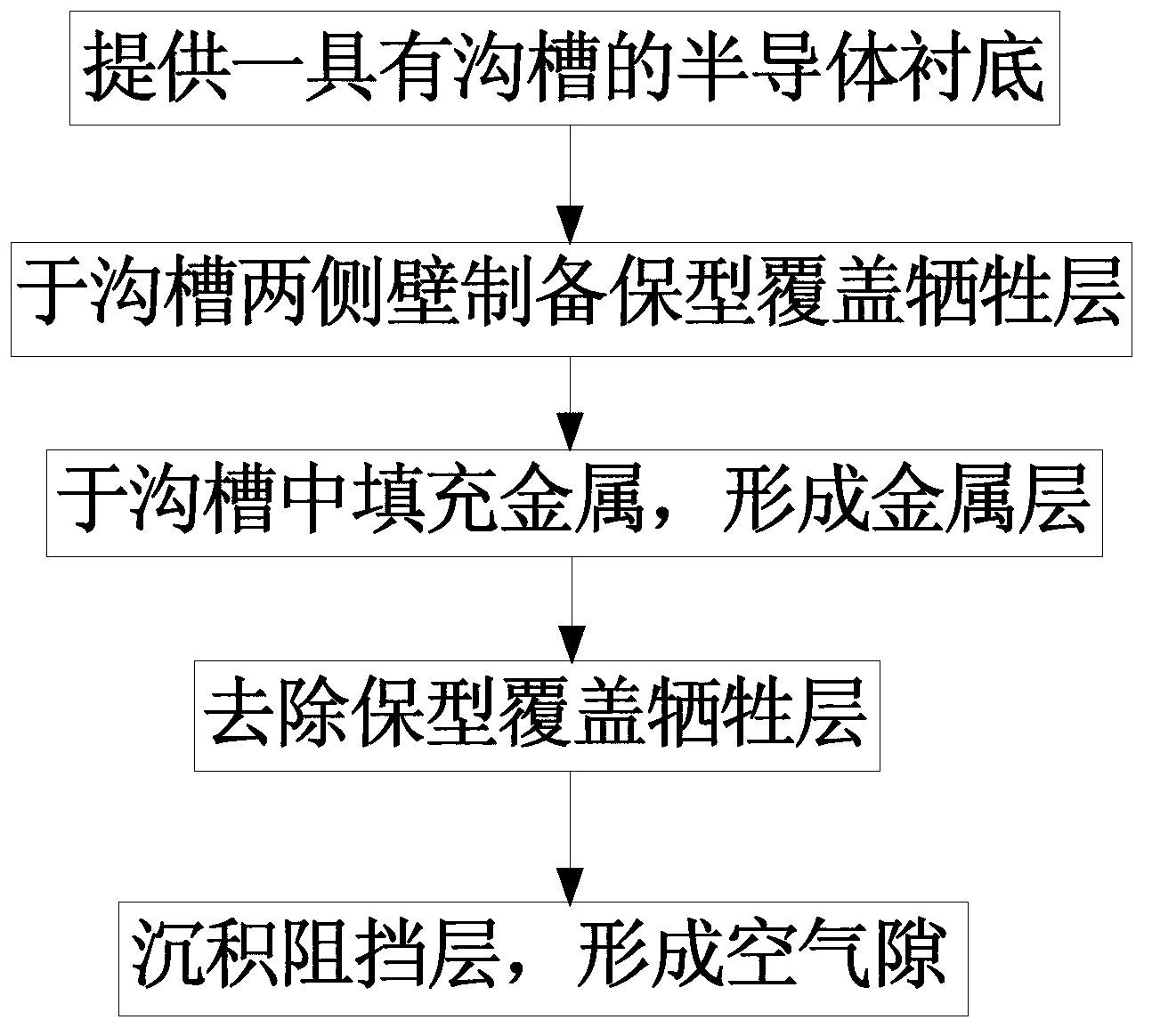

An air gap and trench technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing device manufacturing costs, losing more raw materials, increasing production costs, etc., achieving less consumables, improving production efficiency, Improve the effect of RC delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

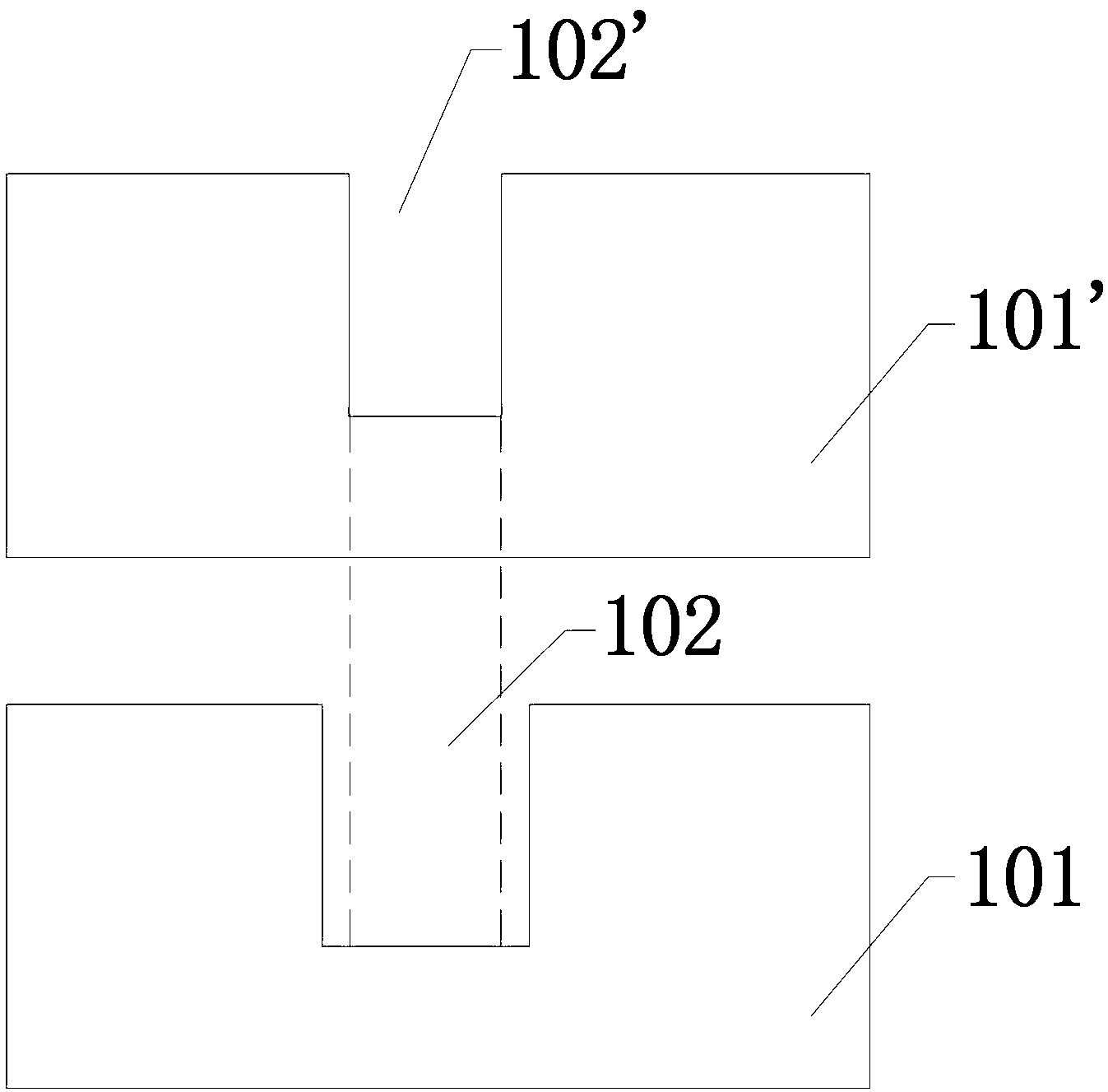

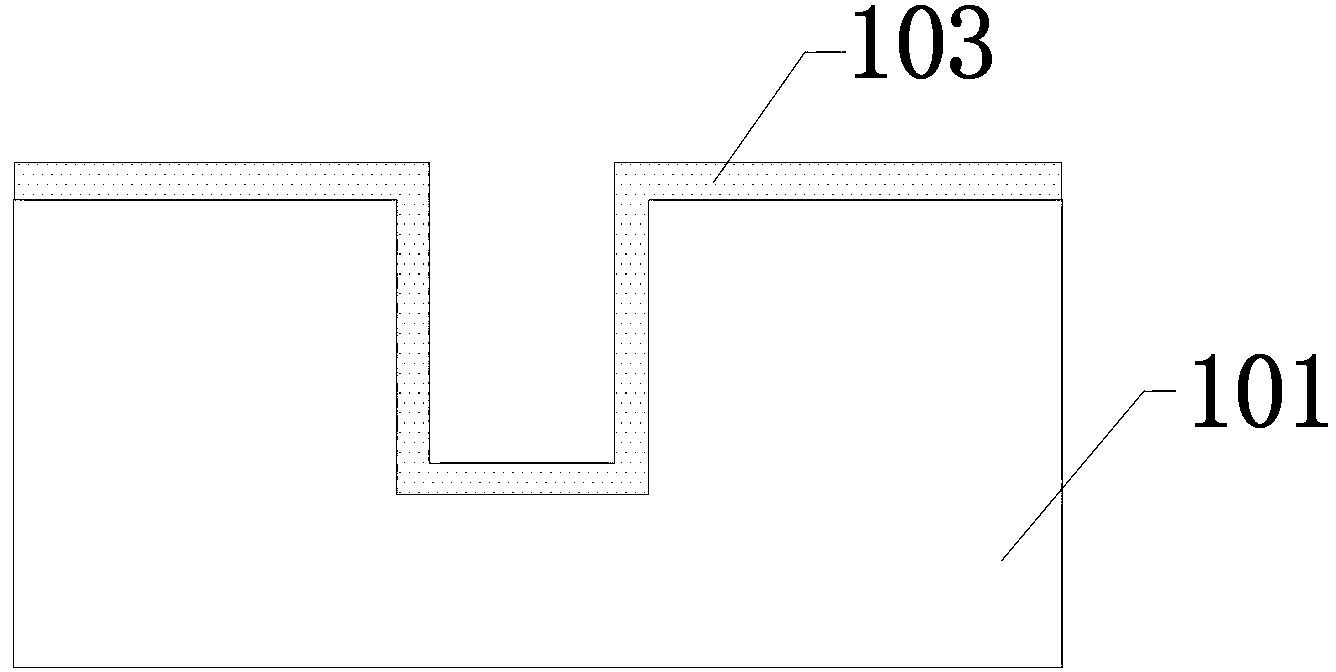

[0061] figure 2 It is a schematic diagram of the comparison between the critical dimensions of the trench design in the traditional process and the key dimensions of the trench design provided in Example 1 of the present invention; as shown in the figure, in the traditional process, the critical dimension of the trench design and the process requirements The critical dimensions are the same, and after subsequent photolithography, etching and wet processing processes, a trench 102' is formed on the semiconductor substrate 101', wherein the wet processing uses ST250 (organic chemicals, here is the American AIMI The company's commercially available organic chemicals (AIMI ST250) liquid medicine and DHF (Dilute Hydrogen Fluoride, dilute hydrofluoric acid solution, non-polar chemical) liquid medicine are used to prevent the existence of residual particles in the groove; in the process of the present invention, the design The critical dimension of the trench is larger than the crit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com