IGBT module parallel connection protection circuit applied to high-power inverter

A technology for protecting circuits and inverters, applied to emergency protection circuit devices, electrical components, etc., can solve problems such as desaturation, IGBT module overheating damage, overheating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

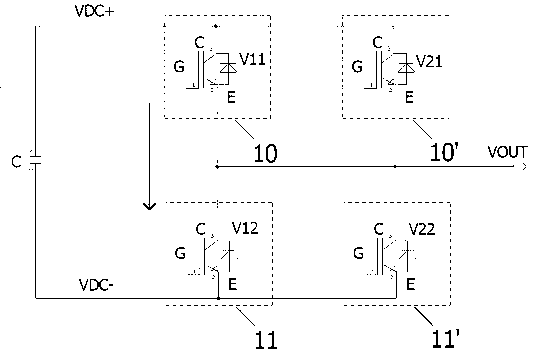

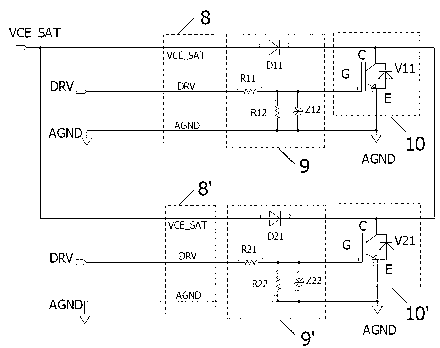

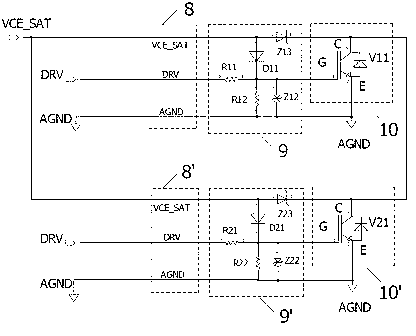

[0015] A parallel protection circuit for IGBT modules applied to high-power inverters, a parallel protection circuit for IGBT modules applied to high-power inverters, the parallel protection circuit includes a circuit for realizing safe shutdown of IGBT modules A soft-off module 5 , the soft-off module 5 is respectively connected to a plurality of saturation voltage drop detection modules, and the plurality of saturation voltage drop detection modules are respectively connected to a feedback optocoupler module 7 .

[0016] like figure 1 As shown, the parallel protection circuit includes a soft turn-off module 5 for realizing the safe shutdown of the IGBT module, and the soft turn-off module 5 is respectively connected with the first Vce saturation voltage drop detection module for detecting the short-circuit fault of the IGBT module 6 is connected to the second Vce saturation voltage drop detection module 6' used to detect the short circuit fault of the IGBT module, and the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap