A structure to enhance the contact strength of electronic circuit surface

An electronic circuit, surface contact technology, applied in the field of communication, can solve the problems of unstable electrical performance, contact failure, large contact resistance, etc., and achieve the effect of reducing unnecessary steps, improving performance stability, and reducing conductive resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

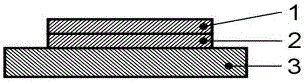

[0024] Such as figure 1 As shown, the first structure provided by the present invention to strengthen the surface contact strength of electronic circuits is used in a communication product. The structure includes an electronic circuit body 3, conductive glue or conductive double-sided tape 2 and a metal sheet 1, wherein the electronic circuit The circuit body 3 is a printed electronic circuit, including a laser direct structuring (LDS) circuit, a flexible circuit board or a circuit (PPA) made of pad printing conductive ink; conductive glue or conductive double-sided tape 2 is a reinforcing material with good conductivity The metal sheet 1 is a conductive material with good strength and toughness, including stainless steel sheet, copper sheet or other metal sheets with good conductivity; The two are connected and fixed to form an integral body, so that the electronic circuit body 3 is connected with the spring pins or pins on the main board, and the damage of the electronic cir...

Embodiment 2

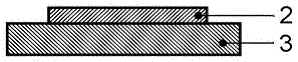

[0029] Such as figure 2 As shown, the second structure for strengthening the contact strength of the electronic circuit surface provided by the present invention includes an electronic circuit body 3 and a conductive glue or a conductive double-sided adhesive tape 2, wherein the electronic circuit body 3 is a printed electronic circuit, including Laser Direct Structuring (LDS) circuits, flexible circuit boards or circuits made of pad printing conductive ink (PPA), conductive glue or conductive double-sided tape 2 are conductive materials with good conductivity; by applying conductive glue or conductive double-sided tape 2 Uniformly cover the surface of the electronic circuit body 3 to solidify the two into one body, thereby connecting the electronic circuit body 3 with the spring pins or spring pins on the main board, and avoiding damage to the electronic circuit body 3 .

[0030] Wherein, the specific steps of the manufacturing method of the structure having two layers of el...

Embodiment 3

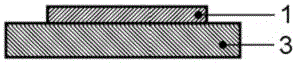

[0034] Such as image 3 As shown, the present invention proposes a third structure for strengthening the contact strength of the electronic circuit surface, which is used in a communication product. The strengthening structure includes an electronic circuit body 3 and a metal sheet 1, wherein the electronic circuit body 3 is a printed electronic circuit , or a circuit (PPA) made of pad printing conductive ink, the metal sheet 1 is a conductive material with good toughness, such as a stainless steel sheet, copper sheet or other metal sheets with good conductivity; the electronic circuit body made of nano-silver 3 is relatively soft, and before the electronic circuit body 3 is cured, the metal sheet is evenly covered on the electronic circuit body 3, and after curing, the two are combined to form a whole, so as to realize the connection of other components of the electronic circuit body 3 and avoid the electronic circuit Damage to body 3.

[0035] Wherein, the specific steps of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com