High heat conduction substrate and manufacturing method thereof

A high thermal conductivity, substrate technology, applied in printed circuit manufacturing, printed circuit parts, electrical components, etc., can solve the problems of easy diffusion, insulation decline, low thermal expansion coefficient, etc., and achieve the solution of buffer layer metal diffusion and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

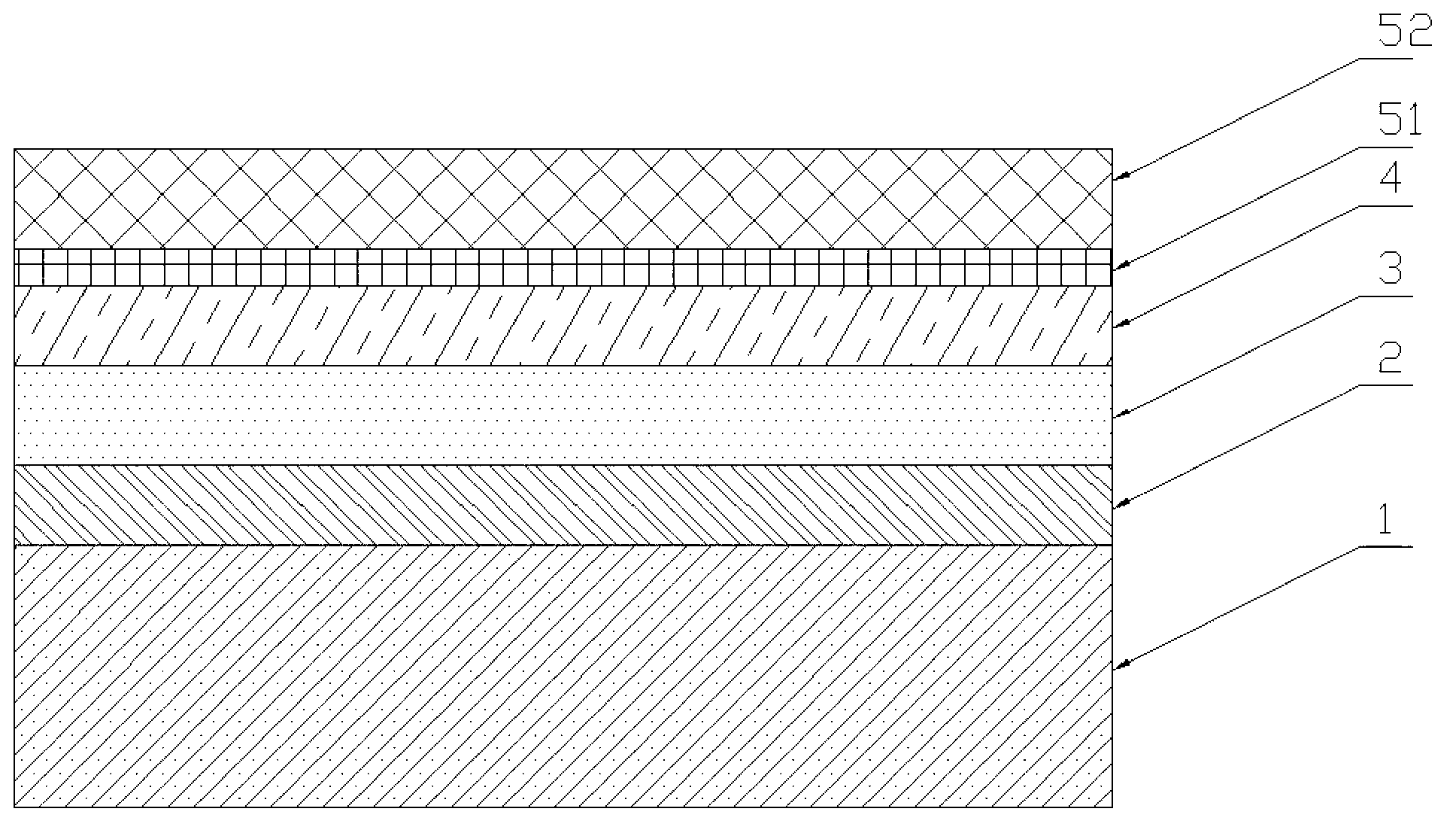

[0028] A method for preparing a high thermal conductivity substrate, characterized in that: comprising the following steps:

[0029] 1) A layer of aluminum is formed on one side of the alloy buffer layer by physical vapor deposition or hot-dip plating to form a connection layer between the aluminum substrate and the buffer layer, and then the alloy buffer layer is connected to the aluminum substrate by diffusion welding;

[0030] 2) Cover a layer of aluminum on the other side of the buffer layer by physical vapor deposition or hot-dip plating;

[0031] 3) Use anodic oxidation or micro-arc oxidation to convert the aluminum layer in the previous step into an aluminum oxide insulating layer;

[0032] 4) A primary conductive layer is formed on the surface of the insulating layer by physical vapor deposition; a secondary conductive layer is formed on the surface of the primary conductive layer by electrochemical deposition.

[0033] The anodic oxidation solution used in the anodic...

Embodiment 1

[0040] A method for preparing a high thermal conductivity substrate, comprising the steps of:

[0041] 1) A layer of 10 μm metal aluminum is formed on one side of the 50 μm molybdenum-copper alloy buffer layer by evaporation, which is used as the connection layer between the aluminum substrate and the buffer layer;

[0042] 2) The buffer layer and the aluminum substrate are connected by the connection layer by means of diffusion welding;

[0043] 3) Cover the other side of the molybdenum-copper alloy buffer layer with an aluminum layer by evaporation plating (the thickness of the aluminum layer is such that after anodic oxidation becomes an insulating layer, the thickness of the insulating layer is 10 μm);

[0044] 4) Through anodic oxidation, the aluminum layer is converted into an aluminum oxide insulating layer;

[0045] 5) The conductive layer is processed in this way: first magnetron sputtering metallic silver 300 ?

[0046] The coefficient of thermal expansion of the all...

Embodiment 2

[0050] A method for preparing a high thermal conductivity substrate, comprising the steps of:

[0051] 1) Form a layer of 50 μm metal aluminum on one side of the 200 μm titanium-copper alloy buffer layer by evaporation, and use it as the connection layer between the aluminum substrate and the buffer layer;

[0052] 2) The buffer layer and the aluminum substrate are connected by the connection layer by means of diffusion welding;

[0053] 3) Cover the other side of the titanium-copper alloy buffer layer with an aluminum layer by hot-dip plating (the thickness of the aluminum layer is such that after micro-arc oxidation becomes an insulating layer, the thickness of the insulating layer is 100 μm);

[0054] 4) Through micro-arc oxidation, the aluminum layer is converted into an aluminum oxide insulating layer;

[0055] 5) The conductive layer is processed in this way: first magnetron sputtering metal silver 850? on the insulating layer to realize its conductivity, and then elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com