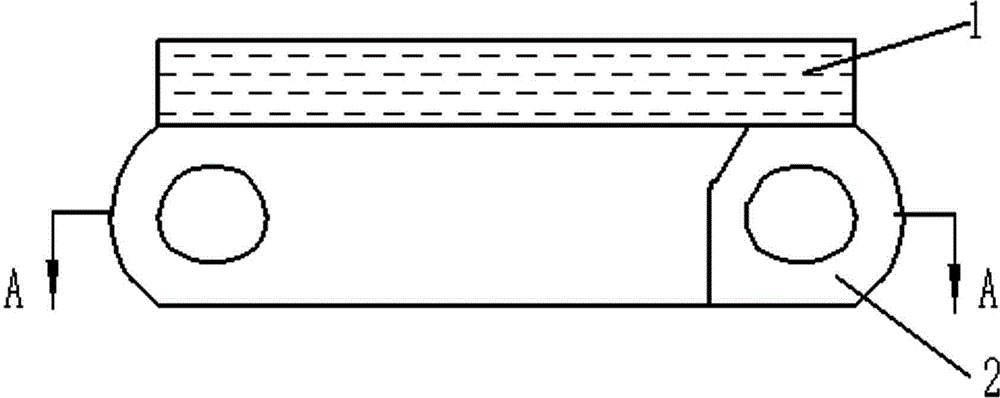

Heat-resistant microwave-radiable conveying belt for microwave exfoliated graphite and manufacturing method of conveying belt

A technology of microwave puffing and conveyor belt, applied in the field of conveyor belt, can solve the problems of poor stability and low high temperature resistance, and achieve the effects of good high temperature oxidation resistance, long service life and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a. Raw material drying

[0024] Weigh 500g of polypropylene and dry it in a plastic hopper dryer at 100°C for 4h.

[0025] b.Plastification

[0026] The dried polypropylene is put into the cylinder of the screw injection molding machine to be plasticized to a molten state. The temperature of the cylinder is 210°C, the degree of vacuum is 0.06Mpa, and the plasticizing back pressure is 3Mpa.

[0027] c. Injection molding filling

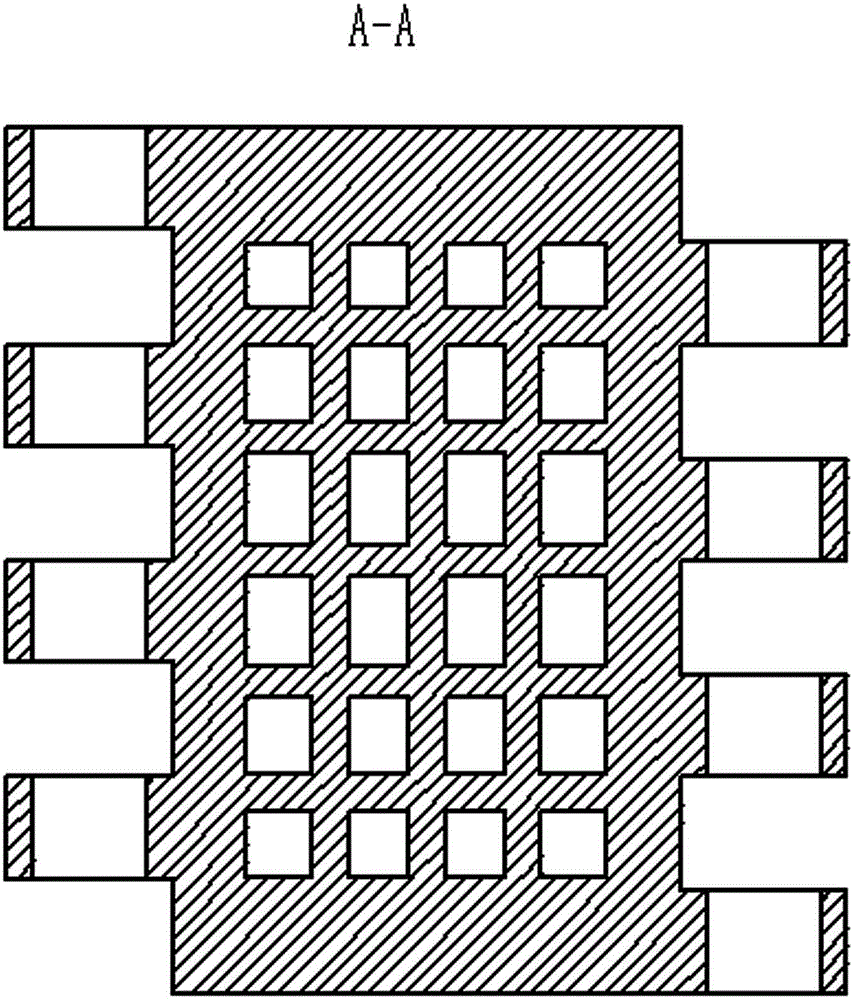

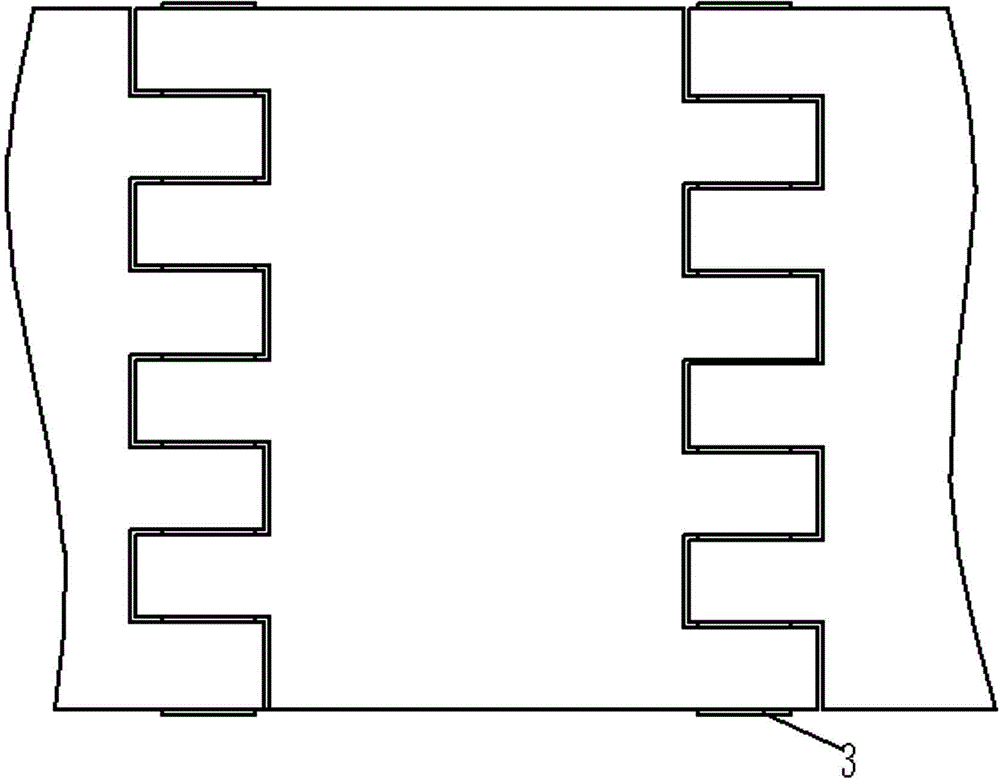

[0028] The aluminum silicate fiber blanket 1 is placed in the cavity of the closed mold of the screw injection molding machine. The temperature of the closed mold is 60° C., and the polypropylene melt is subjected to the following steps: i. Under pressure, inject polypropylene into the closed cavity of the closed mold through the nozzle, runner and gate, the injection pressure is 100MPa, and the injection speed is 40 rpm; ii Flow filling: the polypropylene melt fills the entire cavity The closed cavity of the mould; Ⅲ cooling and setting: the...

Embodiment 2

[0033] a. Raw material drying

[0034] Weigh 500g of polypropylene and dry it in a plastic hopper dryer at 110°C for 4.5h.

[0035] b.Plastification

[0036] The dried polypropylene is put into the cylinder of the screw injection molding machine to be plasticized to a molten state. The temperature of the cylinder is 200° C., the degree of vacuum is 0.04 MPa, and the plasticizing back pressure is 4 MPa.

[0037] c. Injection molding filling

[0038] The aluminum silicate fiber blanket 1 is placed in the cavity of the closed mold of the screw injection molding machine. The temperature of the closed mold is 65° C., and the polypropylene melt is subjected to the following steps: i. Under pressure, inject polypropylene into the closed cavity of the closed mold through the nozzle, sprue and gate, the injection pressure is 110MPa, and the injection speed is 40 rpm; ii Flow filling: the polypropylene melt fills the entire cavity The closed cavity of the mould; Ⅲ cooling and setting...

Embodiment 3

[0043] a. Raw material drying

[0044] Weigh 500g of polypropylene and dry it in a plastic hopper dryer at 110°C for 5h.

[0045] b.Plastification

[0046] The dried polypropylene is put into the barrel of the screw injection molding machine to be plasticized to a molten state. The temperature of the barrel is 220°C, the degree of vacuum is 0.03Mpa, and the plasticizing back pressure is 2MPa.

[0047] c. Injection molding filling

[0048] The aluminum silicate fiber blanket 1 is placed in the cavity of the closed mold of the screw injection molding machine. The temperature of the closed mold is 55° C., and the polypropylene melt is subjected to the following steps: i. Under pressure, polypropylene is injected into the closed cavity of the closed mold through the nozzle, runner and gate, the injection pressure is 120MPa, and the injection speed is 45 rpm; ii Flow filling: the polypropylene melt fills the entire cavity The closed cavity of the mould; Ⅲ cooling and setting: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com