System and method for simultaneous dry-method hydrogen production from catalytic methane decomposition and carbon dioxide separation

A carbon dioxide and methane catalysis technology, applied in chemical instruments and methods, hydrogen, chemical recovery, etc., can solve the problems of loss of catalytic performance, easy carbon deposition of catalysts, reduction of process stability and continuity, etc., to achieve the elimination of carbon deposition routes, Reduce costs and overcome the effect of complex separation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

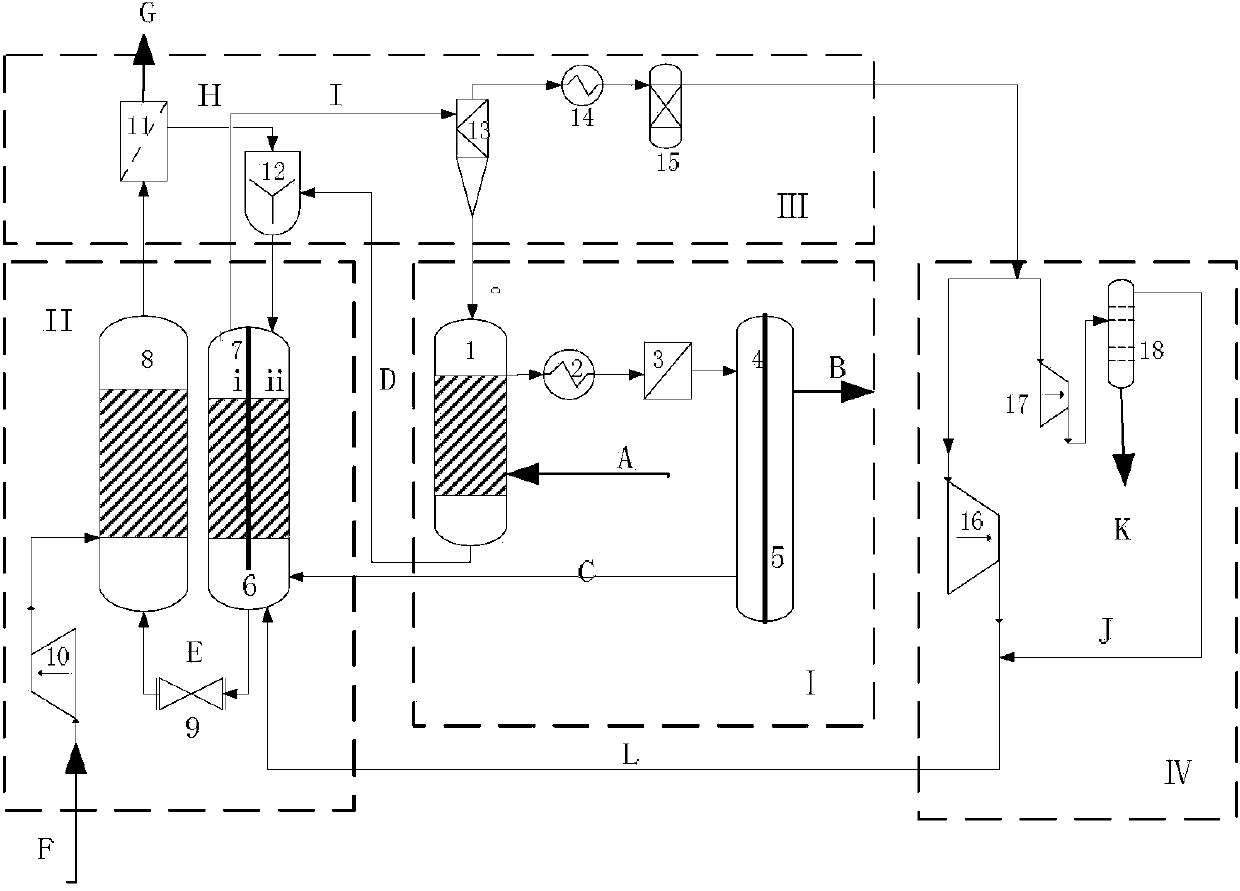

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0041] The invention provides a system and method for catalytically decomposing methane in a dry process to produce hydrogen while separating carbon dioxide. In the method, methane is catalytically decomposed to produce hydrogen, and the obtained gas phase products are separated to obtain high-purity hydrogen. Undecomposed or incompletely decomposed methane and carbon deposits on the catalyst are eliminated through catalyst regeneration, and used as a heat source to heat the regenerated catalyst to accelerate the catalytic reaction.

[0042] Through the reasonable combination of the two processes of hydrogen production by catalytic methane decomposition and catalyst regeneration, technical problems such as large water consumption, coking and deactivation of catalysts, supply of reaction heat, separation of carbon dioxide and difficulties in hydrogen purif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com