Method for recovering aluminum oxide from waste FCC catalyst

A catalyst and alumina technology, applied in alumina/aluminum hydroxide and other directions, can solve problems such as increasing the difficulty of aluminum recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

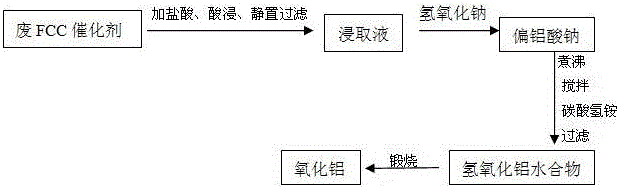

[0019] The present invention provides a kind of method that reclaims alumina from spent FCC catalyst, further illustrate technical scheme of the present invention through specific implementation below:

[0020] Step 1: Use hydrochloric acid with a mass concentration of 4.04% to convert the FCC catalyst into a hydrochloric acid double salt leaching solution under the conditions of 60°C, a mechanical stirring speed of 300 r / min, and a leaching time of 6 hours;

[0021] Step 2: Add a sodium hydroxide solution with a concentration of 1mol / L to the leaching solution to convert metal ions into their hydroxide precipitates, while only Al(OH)3 can react with strong alkali in the metal hydroxide precipitates in FCC Generate water-soluble sodium metaaluminate;

[0022] Step 3: separating the water-soluble sodium metaaluminate from the waste FCC by filtering;

[0023] Step 4: Boil the obtained sodium metaaluminate solution, add 40% ammonium bicarbonate solution under the condition of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com