A method for producing foam glass products at low temperature

A foam glass and product technology, which is applied in the field of low temperature production of foam glass products with high strength, can solve the problems of high foaming temperature, high energy consumption, not conforming to environment-friendly materials, etc., and achieves improved strength, reduced production cost, The effect of enhancing the strength of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

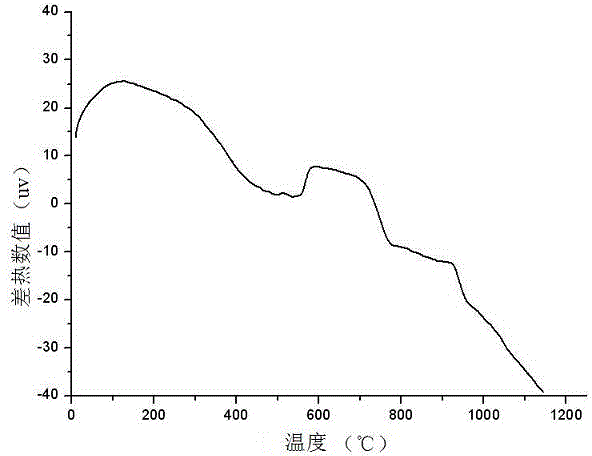

[0022] Depend on figure 1 It can be seen that figure 1 It is the DTA curve of the glass powder, and the softening temperature of the glass powder can be obtained through this curve, so as to determine the heat treatment process of the foam glass. Before 600°C, the curve fluctuates greatly, which may be due to the evaporation of water and the reaction inside the glass powder. There is an endothermic peak around 750°C, but it is not very obvious, so the softening temperature and endothermic peak of the glass cannot be directly determined. It is about 750°C, so the softening temperature of the glass frit is tentatively set at 750°C.

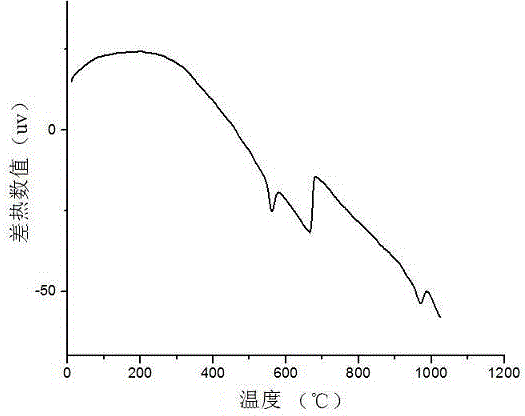

[0023] like figure 2 as shown, figure 2 It is the DTA curve of manganese dioxide, through which the decomposition temperature of manganese dioxide can be analyzed to determine whether it can release gas when the glass powder is softened. The DTA curve of manganese dioxide has an endothermic peak at 525-700°C, which is due to the decomposit...

Embodiment 2

[0030] Glass powder 100, manganese dioxide 1, sodium fluorosilicate 3, sodium phosphate 3, sodium carbonate 10, carbon fiber 1. The preheating temperature is 430°C, the time is 10 minutes, the foaming temperature is 780°C, the time is 7 minutes, the annealing temperature is 500°C, and the holding time is 30 minutes. The pore size of the prepared foam glass is small, less than 1mm, and the apparent density is 0.552g / cm 3 , The compressive strength is 5.16MPa.

Embodiment 3

[0032] Glass powder 100, manganese dioxide 3, sodium fluorosilicate 5, sodium phosphate 4, sodium carbonate 5, carbon fiber 3. The preheating temperature is 430°C, the time is 15 minutes, the foaming temperature is 750°C, the time is 10 minutes, the annealing temperature is 500°C, and the holding time is 30 minutes. The prepared foam glass has a relatively uniform pore size of about 2mm and an apparent density of 0.546g / cm 3, The compressive strength is 6.08 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com