Preparation method of crosslinked-acetylated-octenyl succinic acid ester ternary composite modified starch

A technology of octenyl succinate and ternary compounding, which is applied in the field of starch modification, can solve the problems of application limitations, modified starch products cannot meet the requirements, etc., achieve high peak viscosity, strong gel type, and improve pasting properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

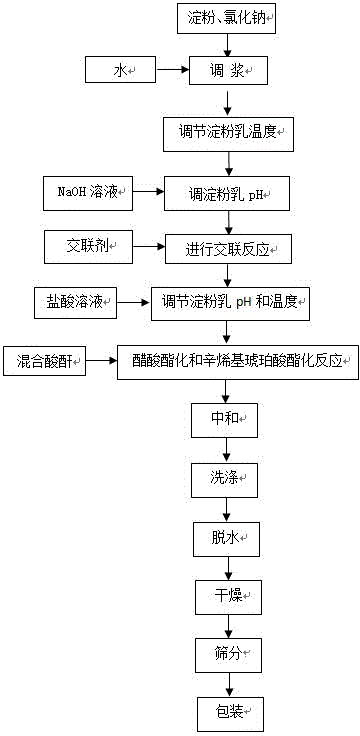

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of composite modified starch, this method is raw material with potato starch, adopts wet method to prepare cross-linking-acetylation-octenyl succinate ternary composite modified starch, and its specific steps are as follows:

[0035] Step 1: 1000kg of potato starch and water are mixed into starch milk with a concentration of 38% by mass, adding 10kg of sodium chloride, adjusting the pH value to 11.0 with a concentration of 3% by mass of sodium hydroxide solution, and raising the temperature to 25°C ;

[0036] Step 2: add 0.15 kg of phosphorus oxychloride, react for 2 hours, add hydrochloric acid with a concentration of 5% by mass to adjust the pH value to 8.5;

[0037] Step 3: Add 60kg of mixed acid anhydride, which is formed by mixing octenyl succinic anhydride and acetic anhydride in a mass ratio of 1:5, and maintain the pH of the system with a sodium hydroxide solution with a concentration of 3% by mass The pH value is 8.5, react for 1 h...

Embodiment 2

[0040] A preparation method of composite modified starch, the method uses tapioca starch as raw material, adopts wet method to prepare cross-linking-acetylation-octenyl succinate ternary composite modified starch, and its specific steps are as follows:

[0041] Step 1: 1000kg tapioca starch and water are made into starch milk with a concentration of 40% by mass, add 5kg of sodium chloride, adjust the pH value to 11.5 with a concentration of 3% by mass of sodium hydroxide solution, and heat up to 25°C .

[0042] Step 2: Add 0.10 kg of phosphorus oxychloride, react for 2.5 hours, and add hydrochloric acid solution with a concentration of 5% by mass to adjust the pH value to 9.0.

[0043] Step 3: Add 50kg of mixed acid anhydride, which is formed by mixing octenyl succinic anhydride and acetic anhydride in a mass ratio of 1:4, and maintain the pH value with a sodium hydroxide solution with a concentration of 3% by mass 9.0, react for 1.5h, and adjust the pH value to 6.5 with ...

Embodiment 3

[0046] A preparation method of composite modified starch, the method uses waxy cornstarch as raw material, adopts wet method to prepare crosslinking-acetylation-octenyl succinate ternary composite modified starch, and its specific steps are as follows:

[0047] Step 1: 1000kg waxy cornstarch and water are made into the starch milk that concentration is 38% by mass fraction, add 15kg sodium chloride, be that the sodium hydroxide solution of mass fraction 4% is adjusted pH value to 11.0 with concentration, be warming up to 30°C;

[0048] Step 2: Add 0.20kg of phosphorus oxychloride, react for 1.5h, add hydrochloric acid solution with a concentration of 5% by mass to adjust the pH value to 9.0;

[0049] Step 3: Add 30kg of mixed acid anhydride, which is formed by mixing octenyl succinic anhydride and acetic anhydride in a ratio of 1:6 by mass, adjusted with a sodium hydroxide solution with a concentration of 3% by mass to maintain the system pH value to 9.5, react for 2 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com