Production method of novel zwitterionic polyvinyl butyral resin

A polyvinyl butyral resin and amphoteric ion technology, which is applied in the production field of new zwitterionic polyvinyl butyral resin, can solve problems such as increased haze, decreased transparency, and decreased cohesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

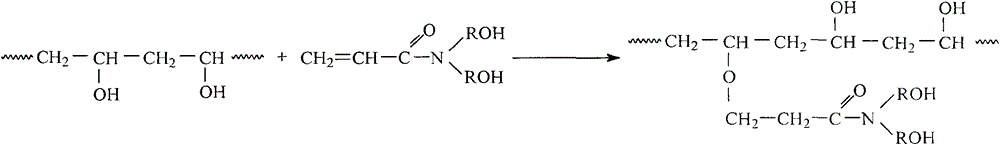

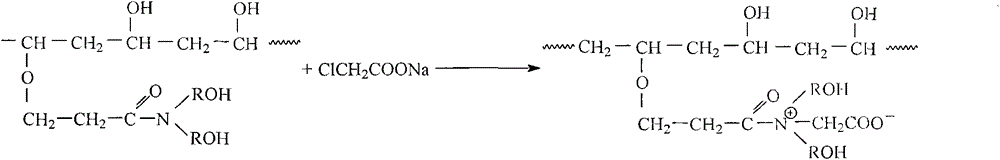

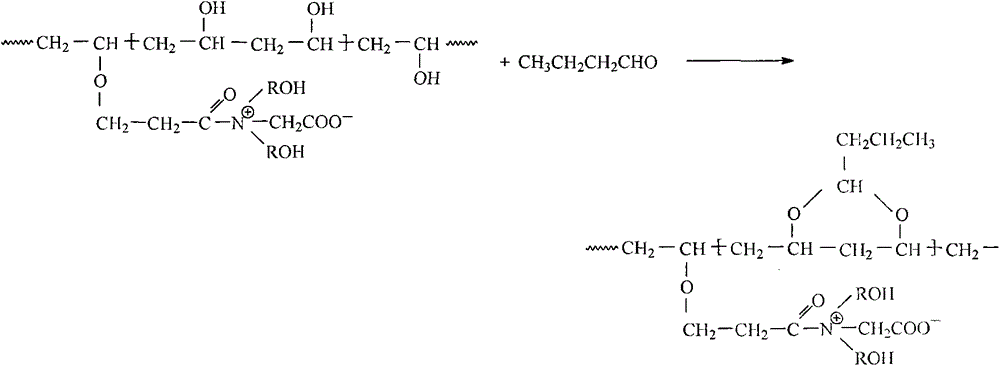

Method used

Image

Examples

Embodiment 1

[0031] Add 100g of PVA1799 into 900g of distilled water, stir to dissolve, configure it into a 10% PVA aqueous solution, adjust the pH value of the system to 9 with NaOH; add 0.045mol N,N-dimethylolacrylamide to the system, and stir at 80°C for 3 hours; then add 0.045mol sodium chloroacetate to the system, and stir and react at 80°C for 30min.

[0032] Cool the system down to 10°C, add 0.25g of sodium dodecylbenzenesulfonate, 9g of 36% hydrochloric acid, stir and mix evenly; then slowly add 57g of n-butyraldehyde dropwise for 30min. During the feeding process, the temperature of the system will rise slightly, and white polyvinyl butyral resin will start to precipitate. Control the system to react at 10°C for 30 minutes; then raise the temperature to 70°C in 90 minutes, and then adjust the pH of the system with 4.5g of sodium hydroxide 10, and then kept at 70°C for 60 minutes, filtered, washed 4 times with hot water at 70°C, and dried to obtain 149g of new zwitterionic polyviny...

Embodiment 2

[0034] Add 200g of PVA2199 into 3800g of distilled water, stir to dissolve, configure it into a 5% PVA aqueous solution, adjust the pH value of the system to 9 with KOH; add 0.18mol N,N-dihydroxyethylacrylamide to the system, and stir at 60°C for 5 hours; then add 0.18mol sodium chloroacetate to the system, and stir and react at 60°C for 60min.

[0035]Cool the system down to 12°C, add 0.45g maleic anhydride dioctyl sodium sulfonate, 20g 36% hydrochloric acid, stir and mix evenly; then slowly add 120g n-butyraldehyde dropwise for 60min. During the feeding process, the temperature of the system will rise slightly, and white polyvinyl butyral resin will start to precipitate. Control the system to react at 10-12°C for 60nin; The pH of the system is 10, and the reaction is maintained at 70°C for 60 minutes, filtered, washed three times with hot water at 65°C, and dried to obtain the new zwitterionic polyvinyl butyral resin 302.

Embodiment 3

[0037] Add 50g of PVA1099 into 284g of distilled water, stir to dissolve, and configure it into a 15% PVA aqueous solution. Use KOH to adjust the pH value of the system to 9; add 0.03mol N, N-dihydroxyethylacrylamide to the system, and stir at 50°C for reaction 6 hours; then add 0.03mol sodium chloroacetate to the system, and stir and react at 50°C for 50min.

[0038] 100 g of methanol was added to the system, and a white solid precipitated out of the system, which was filtered and dried to obtain 51 g of modified PVA.

[0039] Dissolve the modified PVA into 459g of dimethyl sulfoxide, add 4g of sulfuric acid under stirring, control the temperature of the system at about 60°C, and add 35g of butyraldehyde dropwise, and the dropping time is controlled at 40min. After the dropwise addition was completed, the mixture was incubated at 70° C. for 100 minutes. Add 82g of warm water to the system under high-speed stirring, precipitate solids, filter, wash with warm water for 5 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com