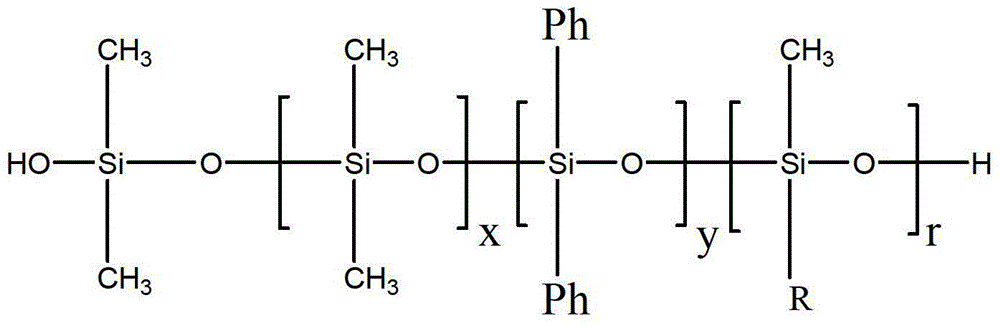

Method for preparing hydroxyl-terminated phenyl amino polyether modified silicone oil

A technology for modification of phenylamino-terminated polyether and polyether, which is applied in textiles, papermaking, fiber treatment, etc., to achieve good smooth hand feeling and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

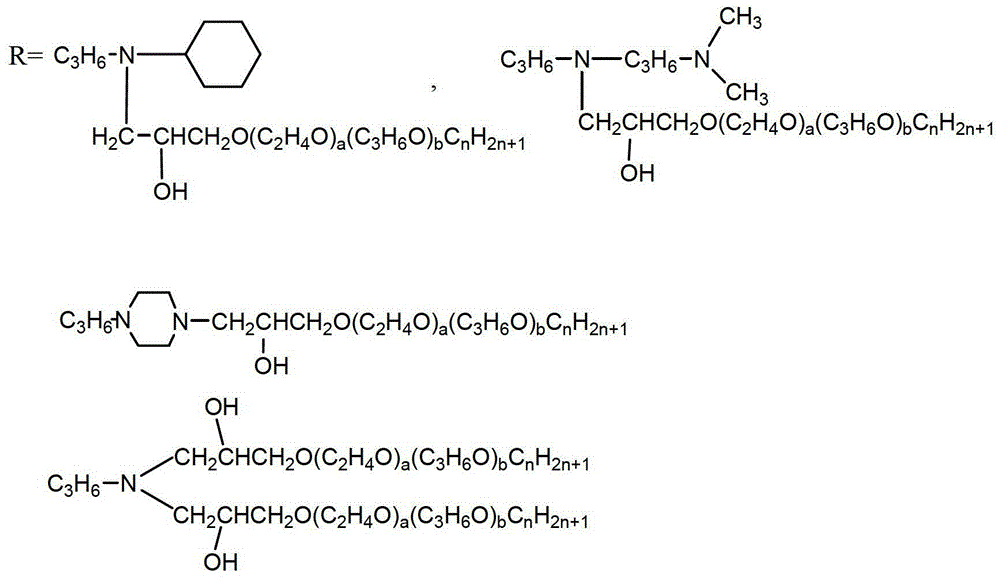

[0024] Example 1: Preparation of a hydroxyl-terminated phenylamino polyether modified silicone oil

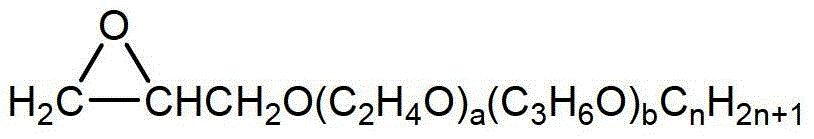

[0025] Step 1) Preparation of polyether-modified aminosilane: Add 150g of 3-piperazinylpropylmethyldimethoxysilane and 175g of alkyl epoxy polyether into a fully dried reaction kettle, seal it and raise the temperature After reaching 60°C, stirring and reacting for 60 minutes; adding catalyst tetramethylammonium hydroxide accounting for 1% of the total weight of the reactants, and continuing to keep warm for 5 hours to obtain the product; the structural formula of the alkyl epoxy polyether is as follows:

[0026]

[0027] In the formula: a and b are both positive integers, and: a=2~8, b=2~15, 0≤n≤4 (integer).

[0028] Step 2) Preparation of hydroxy-terminated phenylamino polyether-modified silicone oil: Take 100g of polyether-modified aminosilane, 200g of dimethoxydiphenylsilane, and 20g of octamethylcyclotetrasiloxane prepared above to react In the kettle, the temperature ...

Embodiment 2

[0031] Example 2: Preparation of a hydroxyl-terminated phenylamino polyether modified silicone oil

[0032] Step 1) Preparation of polyether-modified aminosilane: Add 250g of 3-cyclohexyl-aminopropylmethyldimethoxysilane and 85g of alkyl epoxy polyether into a fully dried reaction kettle, seal it and raise the temperature to 95°C, stirred and reacted for 30 minutes; added a catalyst tetrabutylphosphine hydroxide accounting for 5% of the total weight of the reactants, and continued the heat preservation reaction for 1 hour to obtain final product; the structural formula of the alkyl epoxy polyether is as follows:

[0033]

[0034] In the formula: a and b are both positive integers, and: a=2~8, b=2~15, 0≤n≤4 (integer).

[0035] Step 2) Preparation of hydroxyl-terminated phenylamino polyether-modified silicone oil: add 100 g of polyether-modified aminosilane, 50 g of diphenyldimethoxysilane, and 200 g of octamethylcyclotetrasiloxane prepared above to the reaction In the kettl...

Embodiment 3

[0039] Example 3: Preparation of a hydroxyl-terminated phenylamino polyether modified silicone oil

[0040] Step 1) Preparation of polyether-modified aminosilane: Add 20g of 3-(N,N-dimethylaminopropyl)-aminopropylmethyldimethoxysilane and 120g of alkyl epoxy polyether to In a well-dried reaction kettle, heat up to 85°C in airtight conditions, and stir for 45 minutes to react; add catalyst tetramethylammonium hydroxide accounting for 3% of the total weight of the reactants, and continue to keep warm for 3 hours to obtain; the alkyl ring The structural formula of oxypolyether is as follows:

[0041]

[0042] In the formula: a and b are both positive integers, and: a=2~8, b=2~15, 0≤n≤4 (integer).

[0043]Step 2) Preparation of hydroxyl-terminated phenylamino polyether-modified silicone oil: add 200 g of polyether-modified aminosilane, 150 g of diphenyldimethoxysilane, and 100 g of octamethylcyclotetrasiloxane prepared above to the reaction In the still, heat up to 100°C; add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com