Flue gas sampling system

A sampling system and flue gas technology, applied in the direction of sampling devices, etc., can solve the problems of inaccurate flue gas composition analysis, affecting flue gas composition, blockage of sampling passages, etc., to prevent dust from entering the sampling system, prolong service life, and improve accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

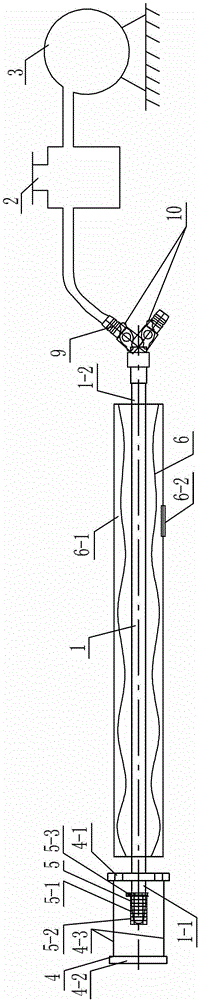

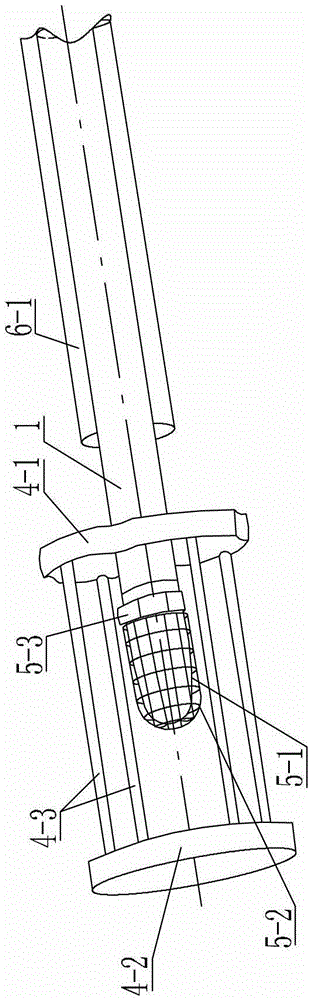

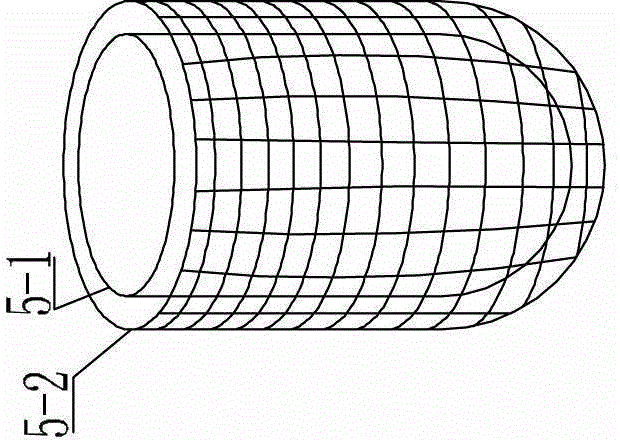

[0013] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, a kind of flue gas sampling system of this embodiment comprises sampling gun, absorbing bottle 2 and sampling pump 3, described sampling gun comprises gun barrel 1, the flue gas outlet end 1-2 of gun barrel 1 and absorbing bottle The inlet of 2 is communicated, the outlet of absorption bottle 2 is communicated with the inlet of sampling pump 3, and described sampling gun also comprises protective cover 4, filtering system 5 and heating system 6;

[0014] The heating system 6 includes a heating sleeve 6-1, and the gun barrel 1 is equipped with a heating sleeve 6-1;

[0015] The protective cover 4 includes a flange 4-1, a protective ring 4-2 and a plurality of pillars 4-3, and the smoke inlet end 1-1 of the gun barrel 1 is inserted in the middle part of the flange 4-1. One end of each pillar 4-3 is connected to the flange 4-1, and the other ends of multiple pillars 4-3 are connected to...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 This embodiment will be described. The heating sleeve 6-1 in this embodiment is an electric heating coil. With such setting, the operation is convenient and the thermal efficiency is high. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 To describe this embodiment, the heating sleeve 6-1 in this embodiment is a resistance heating coil. With such setting, the operation is convenient and the thermal efficiency is higher. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com