Method for testing element distribution in alloy board

A technology for element distribution and alloy plates, applied in the direction of material excitation analysis, thermal excitation analysis, etc., can solve the problem that the smelting and heat treatment process cannot provide quantitative data, the scanning electron microscope energy spectrometer cannot measure the measurement deviation, and the element distribution cannot be quantitatively determined, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

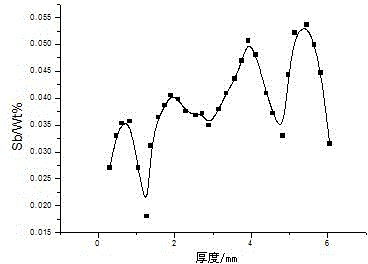

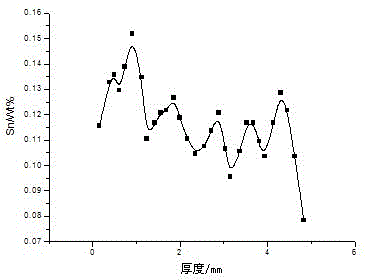

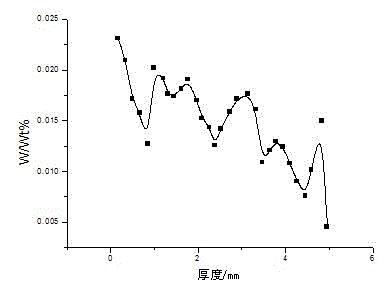

[0027] A method for testing the distribution of elements in alloy sheets. The test object of this embodiment is a strip steel plate with a thickness of 5mm, and the purpose is to test the distribution of Sb, Sn, W, Ni and Cu elements in the strip steel plate. The specific steps are:

[0028] Step 1. Cut out a strip steel plate with a diameter of 10mm and the same thickness as the plate to be tested as a test sample. Except for the upper surface of the sample, the rest of the surface is sealed with epoxy resin AB glue to prepare a test sample .

[0029] Step 2. Take the concentration as 20%HNO 3 solution in a glass container, and then add HNO to the glass container 3 The solution volume is 0.3% mercuric chloride, and the test solution is prepared.

[0030] Step 3: Take 10ml test solution in the first beaker, weigh and record the test sample mass m 0 =3.620g, put the weighed test sample into the first beaker, and stir it with ultrasonic vibration for 30s, take it out, wash ...

Embodiment 2

[0037] A method for testing the distribution of elements in alloy sheets.

[0038] The steps of the method described in this embodiment are as follows: the test object of this embodiment is a cast-rolled aluminum plate with a thickness of 7.3mm, and the purpose is to test the distribution of Si, Zn, Mg, Ti and Mn elements in the cast-rolled aluminum plate. The specific steps are:

[0039] Step 1. Cut a sample with a diameter of 20mm and the same thickness as the plate from the cast-rolled aluminum plate to be tested. Except for the lower surface of the sample, the rest of the surface is sealed with epoxy resin AB glue to prepare a test sample.

[0040] Step 2, take the strong acid solution HCL solution with a concentration of 50% in a glass container, and then add mercuric chloride with a volume of 0.3% of the HCL solution into the glass container to prepare a test solution.

[0041] Step 3: Take 10ml test solution in the first beaker, weigh and record the test sample mass m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com