All solid-state ion selective electrode and preparation method and application thereof

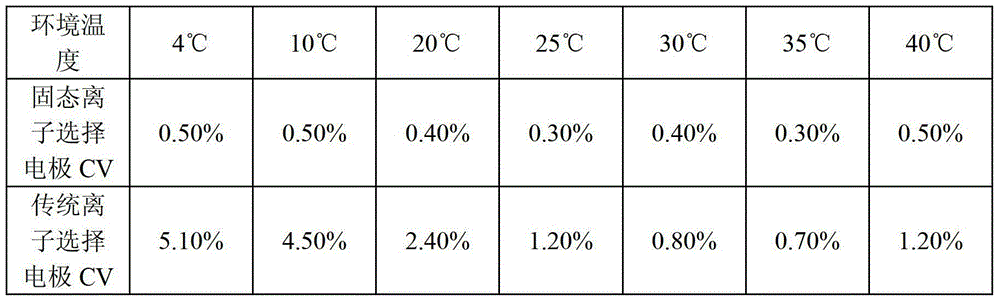

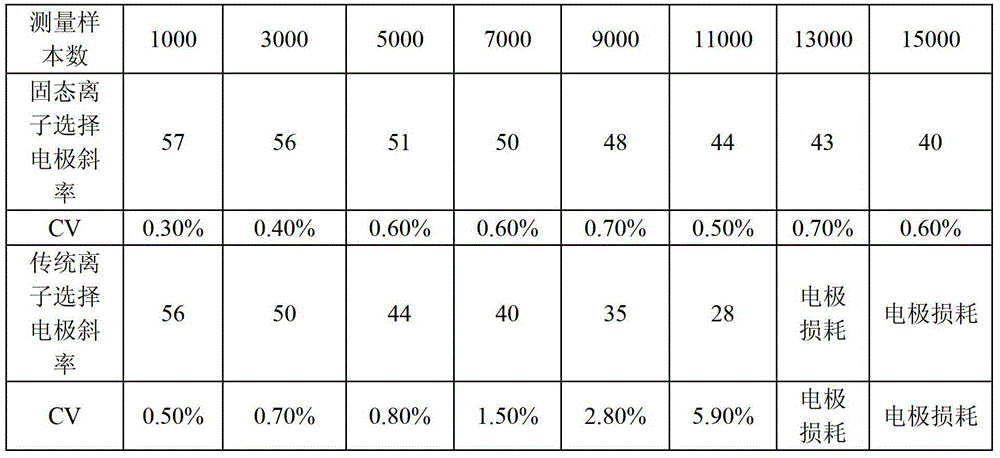

An ion-selective electrode and ion-selective technology, applied in the field of biological and non-biological detection, can solve the problems of difficult maintenance and cleaning, unstable electrode measurement, and narrow temperature adaptability, and achieve wide temperature adaptability, stable measurement, and external interference. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

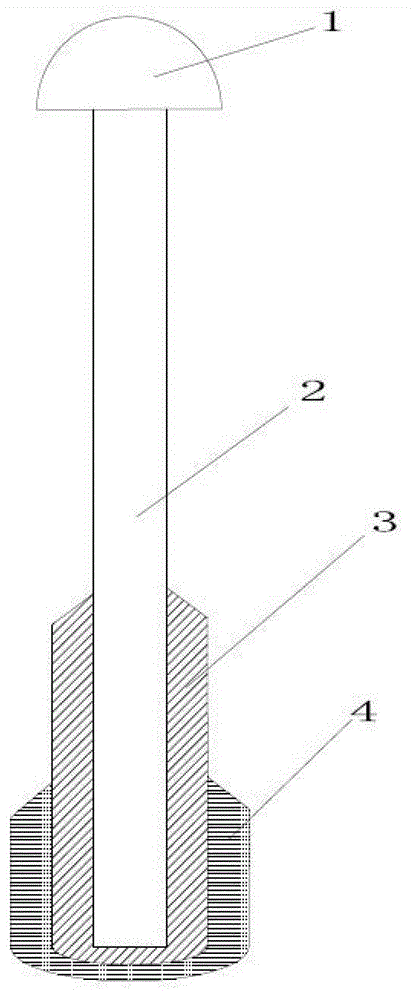

[0023] An all-solid-state ion-selective electrode, comprising an electrode cap 1 and an electrode core 2, the lower part of the electrode core 2 is covered with a conductive polymer layer 3, and the surface of the conductive polymer layer 3 is covered with a layer of ion-selective membrane 4, the conductive The polymer layer 3 contains conductive polymers and lipophilic additives, and the thickness of the ion-selective membrane 4 is 0.5-2 mm. The electrode cap 1 is a mushroom-shaped electrode cap. The electrode cap 1 is an electrode cap formed by closely connecting a gold-plated surface with a silver wire. The thickness of the conductive polymer layer 3 is 10 μm, and the resistance of the conductive polymer layer 3 is 1*10 6 ohm. The conductive polymer is polythiophene. The lipophilic additives are n-butyl acrylate and methyl methacrylate, and the molar ratio of n-butyl acrylate and methyl methacrylate is 80:20. The ion-selective membrane 4 is polyvinyl chloride, co-polyvi...

Embodiment 2

[0030] Basically the same as Example 1, the difference is that the thickness of the conductive polymer layer 3 is 20 μm, and the resistance of the conductive polymer layer 3 is 5*10 6 ohm. The oxidizing agent is 10% perchloric acid. The conductive polymer is polyphenol. The lipophilic additives are n-butyl acrylate and methyl methacrylate, and the molar ratio of n-butyl acrylate and methyl methacrylate is 95:5. The ion-selective membrane 4 is polyvinyl chloride, co-polyvinyl acetate and poly-vinyl alcohol, and the ratio of polyvinyl chloride:co-poly-vinyl acetate:poly-vinyl alcohol is 1:3:6.

[0031] The preparation method of the above-mentioned all-solid-state ion-selective electrode comprises the following steps:

[0032] 1) Preparation of conductive polymer copolymer solution: phenol solution with a volume concentration of 0.01% and an oxidant with a volume concentration of 10% are mixed to obtain a conductive polymer solid-water mixture, and the lipophilic additive and ...

Embodiment 3

[0037] Basically the same as Example 1, the difference is that the thickness of the conductive polymer layer 3 is 15 μm, and the resistance of the conductive polymer layer 3 is 3*10 6 ohm. The oxidizing agent is 6% hypochlorous acid. The conductive polymer is polypyrrole. The lipophilic additives are n-butyl acrylate and methyl methacrylate, and the molar ratio of n-butyl acrylate and methyl methacrylate is 60:40. The ion selective membrane 4 is polyvinyl chloride, co-polyvinyl acetate and poly-vinyl alcohol, and the ratio of polyvinyl chloride:co-poly-vinyl acetate:poly-vinyl alcohol is 1:2:4.

[0038] A method for preparing an all-solid-state ion-selective electrode, comprising the steps of:

[0039] 1) Preparation of conductive polymer copolymer solution: acetylene solution with a volume concentration of 0.005% and an oxidant with a volume concentration of 6% are mixed to obtain a conductive polymer solid-water mixture, and the lipophilic additive and conductive polymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com