Device capable of generating uniform linear laser beams based on high-numerical aperture cylindrical lens focusing

A high numerical aperture, cylindrical lens technology, applied in optics, optical components, instruments, etc., can solve the problems of the complex structure of the beam shaping system and the high price of aspheric lenses, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

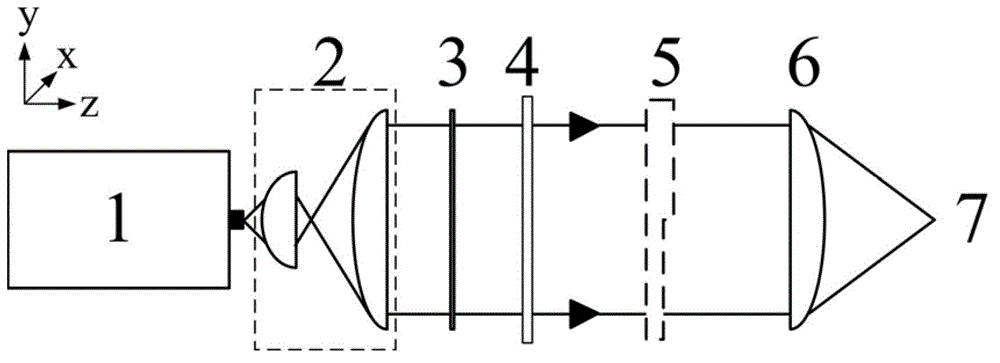

[0015] Such as figure 1 As shown, this embodiment provides a device based on high numerical aperture cylindrical lens focusing to generate a uniform line laser beam, which consists of a linearly polarized laser light source 1, a ball lens group 2, a rectangular diaphragm 3, a half-wave plate 4 and Composed of 6 high numerical aperture cylindrical lenses;

[0016] The light beam generated by the linearly polarized laser light source 1 is expanded and collimated by the ball lens group 2, and the almost uniform rectangular linearly polarized light in the center of the light spot is selected by the rectangular diaphragm 3 to pass through; the rectangular linearly polarized light emitted from the rectangular diaphragm 3 passes through two After the one-third wave plate 4 is focused by a high numerical aperture cylindrical lens 6, a uniform line laser beam is generated at the focal plane.

[0017] In this embodiment, the linearly polarized laser light source 1 is a gas laser light ...

Embodiment 2

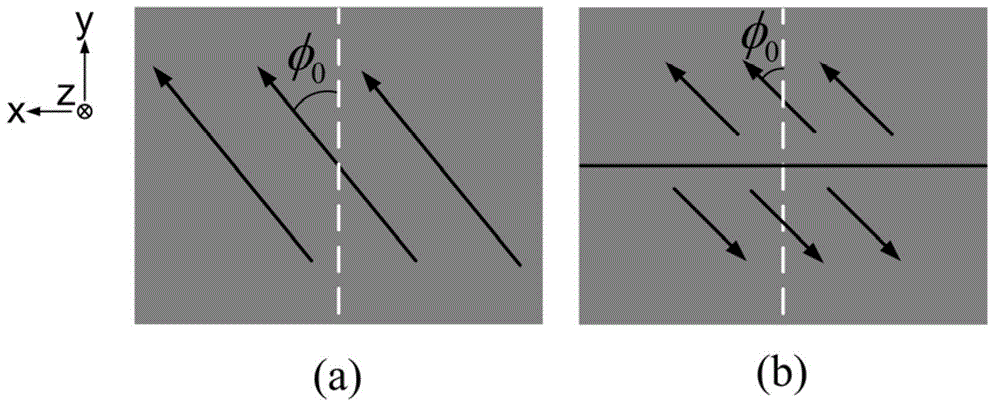

[0037] Such as figure 1 As shown, a discontinuous wave plate 5 is added in the optical path shown in embodiment 1, and the rectangular linearly polarized light is converted into a rectangular TEM 01 Linearly polarized light, rectangular TEM 01 The linearly polarized light is focused on the focal plane 7 by an aplanatic high numerical aperture cylindrical lens 6, and other conditions of this embodiment are the same as those of Embodiment 1.

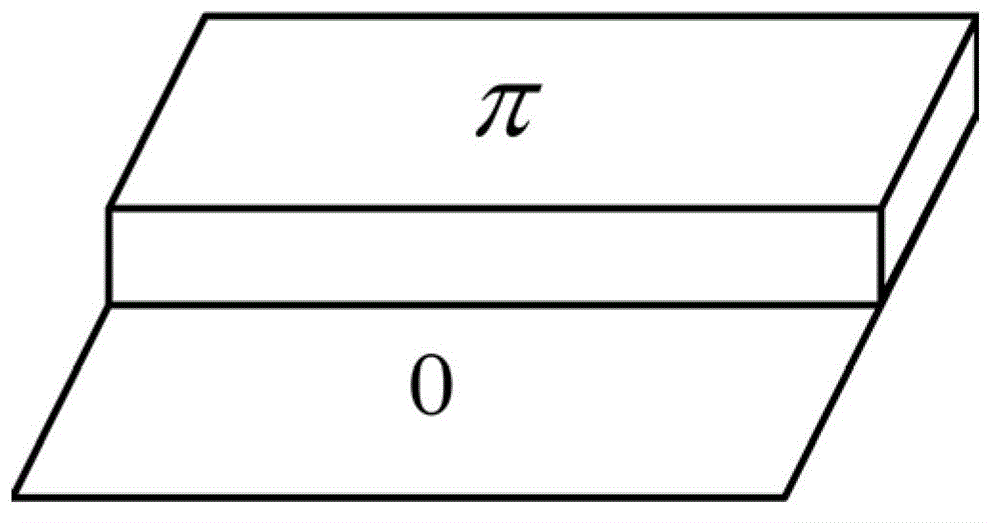

[0038] In this embodiment, there is a specific height difference between the two halves of the discontinuous wave plate 5, so that a relative phase difference of π is generated between the two halves of the beam, thereby converting rectangular linearly polarized light into a rectangular TEM 01 linearly polarized light; and the dividing line between the two halves of the discontinuous wave plate 5 is parallel to the x-axis. The structure diagram of the discontinuous wave plate 5 is as image 3 shown.

[0039] Rectangular TEM 01 The lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com