Natural plant sun cream and preparation process thereof

A preparation process and a technology for sunscreen, applied in the field of natural plant sunscreen and its preparation, can solve the problems of inability to cultivate, easily washed off by sweat, and good heat resistance stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] In the present embodiment, the raw material components and consumption of preparing natural plant sunscreen are:

[0088] water 1000g

[0089] Glycerin 60g

[0090] Isooctyl Palmitate 50g

[0091] Aloe Vera Extract 55g

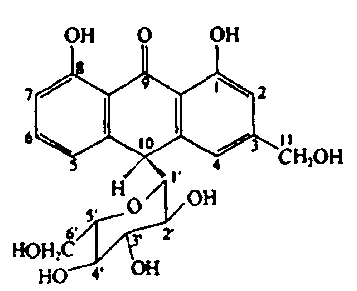

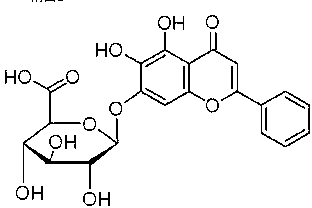

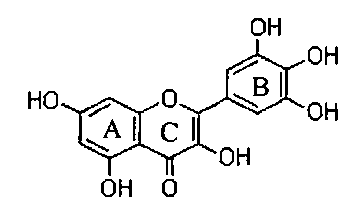

[0092] Scutellaria baicalensis extract 55g

[0093] Red bayberry extract 55g

[0094] Fatty alcohol 17.5g

[0095] Bisabolol 2g

[0096] Dimethicone 17.5g

[0097] Cetyl Polyethylene Glycol / Polypropylene Glycol-10 / 1-Dimethicone 65g

[0098] Methylparaben 3g

[0099] Propylparaben 3g

[0100] Daily fragrance 5g

[0101] Wherein the preparation technology of aloe extract, scutellaria baicalensis extract, bayberry extract is:

[0102] The aloe extract is (1) firstly add aloe gel raw juice and pasty aloe alcohol mixture into a blender for stirring, and mix to form a semi-finished product of the aloe extract. The ingredients of the semi-finished product are composed of the following components by weight percentage: Aloe vera gel raw juice 30%, pa...

Embodiment 2

[0119] In the present embodiment, the raw material components and consumption of preparing natural plant sunscreen are:

[0120] water 900g

[0121] Glycerin 20g

[0122] Isooctyl Palmitate 30g

[0123] Aloe Vera Extract 10g

[0124] Scutellaria baicalensis extract 10g

[0125] Red bayberry extract 10g

[0126] Fatty alcohol 15g

[0127] Bisabolol 1g

[0128] Dimethicone 10g

[0129] Cetyl Polyethylene Glycol / Polypropylene Glycol-10 / 1-Dimethicone 50g

[0130] Methylparaben 1 g

[0131] Propylparaben 1g

[0132] Daily fragrance 2g

[0133] Wherein the preparation technology of aloe extract, scutellaria baicalensis extract, bayberry extract is:

[0134] The aloe extract is (1) firstly add aloe gel raw juice and pasty aloe alcohol mixture into a blender for stirring, and mix to form a semi-finished product of the aloe extract. The ingredients of the semi-finished product are composed of the following components by weight percentage: Aloe gel raw juice 10%, paste aloe al...

Embodiment 3

[0154] In the present embodiment, the raw material components and consumption of preparing natural plant sunscreen are:

[0155] water 1100g

[0156] Glycerin 100 g

[0157] Isooctyl Palmitate 70 g

[0158] Aloe Vera Extract 100 g

[0159] Scutellaria baicalensis extract 100 g

[0160] Bayberry extract 100 g

[0161] Fatty alcohol 20 g

[0162] Bisabolol 3 g

[0163] Dimethicone 25 g

[0164] Cetyl Polyethylene Glycol / Polypropylene Glycol-10 / 1-Dimethicone 80 g

[0165] Methylparaben 5 g

[0166] Propylparaben 5 g

[0167] Daily fragrance 8 g

[0168] Wherein the preparation technology of aloe extract, scutellaria baicalensis extract, bayberry extract is:

[0169] The aloe extract is (1) firstly add aloe gel raw juice and pasty aloe alcohol mixture into a blender for stirring, and mix to form a semi-finished product of the aloe extract. The ingredients of the semi-finished product are composed of the following components by weight percentage: Aloe gel raw juice 50%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com