Preparation method of fibroin microsphere

A technology of silk fibroin and microspheres, applied in animal feed, animal husbandry, applications, etc., can solve the problems of different release mechanisms and time, and achieve the effects of slow and uniform degradation, excellent biocompatibility, and high embedding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

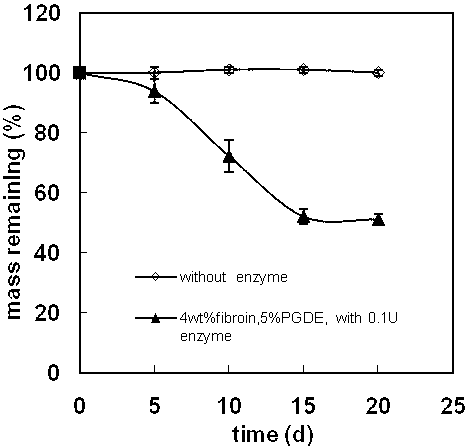

Image

Examples

Embodiment 1

[0019] Prepared in the present embodiment are silk fibroin microspheres of slow-release nano-silver, and the steps of the preparation method of the silk fibroin microspheres are as follows: 1000 grams of silkworm cocoon shells are mixed with 0.5wt% Na 2 CO 3 The aqueous solution degumming is performed twice, 30 minutes each time, the degumming temperature is 100°C, and the bath ratio is 1:100. After degumming, it is fully washed with water and dried at 60°C to obtain silk fibers. with CaCl 2 Aqueous solution dissolves silk fiber, silk fiber: CaCl 2 2H 2 O: water=1g:25g:25ml, the dissolution temperature is 100°C, and the dissolution time is 5min. The solution obtained after dissolving is filtered and injected into a cellulose dialysis membrane for dialysis for 3 days. The molecular weight cut-off of the cellulose dialysis membrane used is 8000-14000. Concentrate the silk fibroin solution to 4wt%, add 0.3wt% nano-silver, dropwise add 5% diglycidyl ether, and mix slowly and ...

Embodiment 2

[0023] Prepared in the present embodiment is the silk fibroin microsphere of slow-release growth factor, and the steps of the preparation method of this silk fibroin microsphere are as follows: 1000 grams of silkworm cocoon shells are mixed with 0.5wt% Na 2 CO 3 The aqueous solution degumming is performed twice, 30 minutes each time, the degumming temperature is 100°C, and the bath ratio is 1:100. After degumming, it is fully washed with water and dried at 60°C to obtain silk fibers. with CaCl 2 Aqueous solution dissolves silk fiber, silk fiber: CaCl 2 2H 2 O: water=1g:25g:25ml, the dissolution temperature is 100°C, and the dissolution time is 5min. The solution obtained after dissolving is filtered, poured into a cellulose dialysis membrane for dialysis for 3 days, and the molecular weight cut-off of the cellulose dialysis membrane used is 8000-14000. The silk fibroin solution was concentrated to 4 wt%. Cool the sterilized silk fibroin solution to about 0°C, add 0.5wt% ...

Embodiment 3

[0026] Prepared in the present embodiment are silk fibroin microspheres of slow-release antimicrobial peptides, and the steps of the preparation method of the silk fibroin microspheres are as follows: 500 grams of silkworm cocoon shells are washed with 0.5wt% Na 2 CO 3The aqueous solution degumming is performed twice, 30 minutes each time, the degumming temperature is 100°C, and the bath ratio is 1:100. After degumming, it is fully washed with water and dried at 60°C to obtain silk fibers. Dissolve silk fiber with calcium chloride, water and ethanol solution with a molar ratio of 1:8:2, the dissolution temperature is 70°C, the bath ratio is 1:25, and the time is 10 minutes. The solution obtained after dissolving is filtered and poured into a cellulose dialysis membrane for dialysis for 3 days. The molecular weight cut-off of the cellulose dialysis membrane used is 8000-14000. Concentrate the silk fibroin solution to 5wt%, add 1wt% antibacterial peptide, add 5wt% ethanol drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com