Drilling machine for machining crankshaft inclined oil hole of engine

An oblique oil hole and engine technology, applied in the direction of drilling dies for workpieces, boring/drilling, metal processing equipment, etc., can solve the problems of high processing difficulty, manual loosening and clamping, cumbersome steps, etc. The effect of service life, improving machining accuracy and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

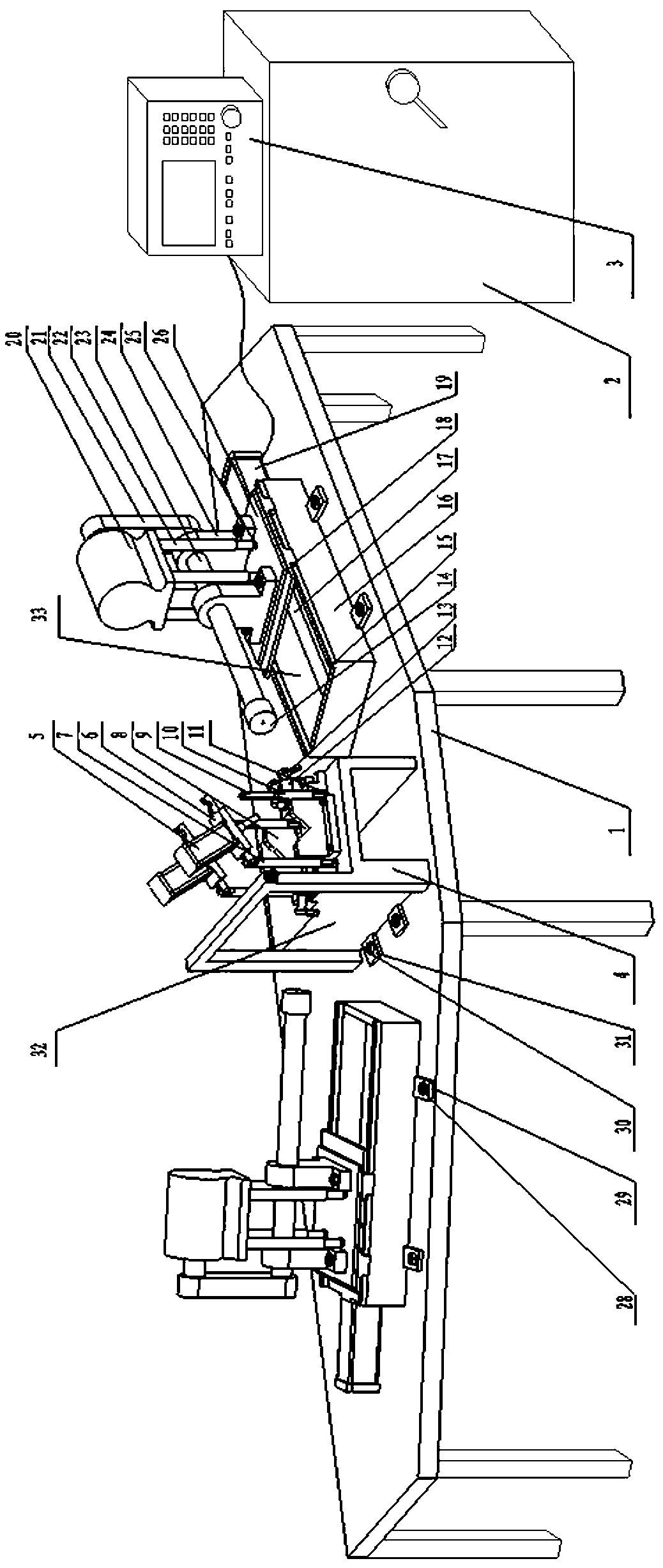

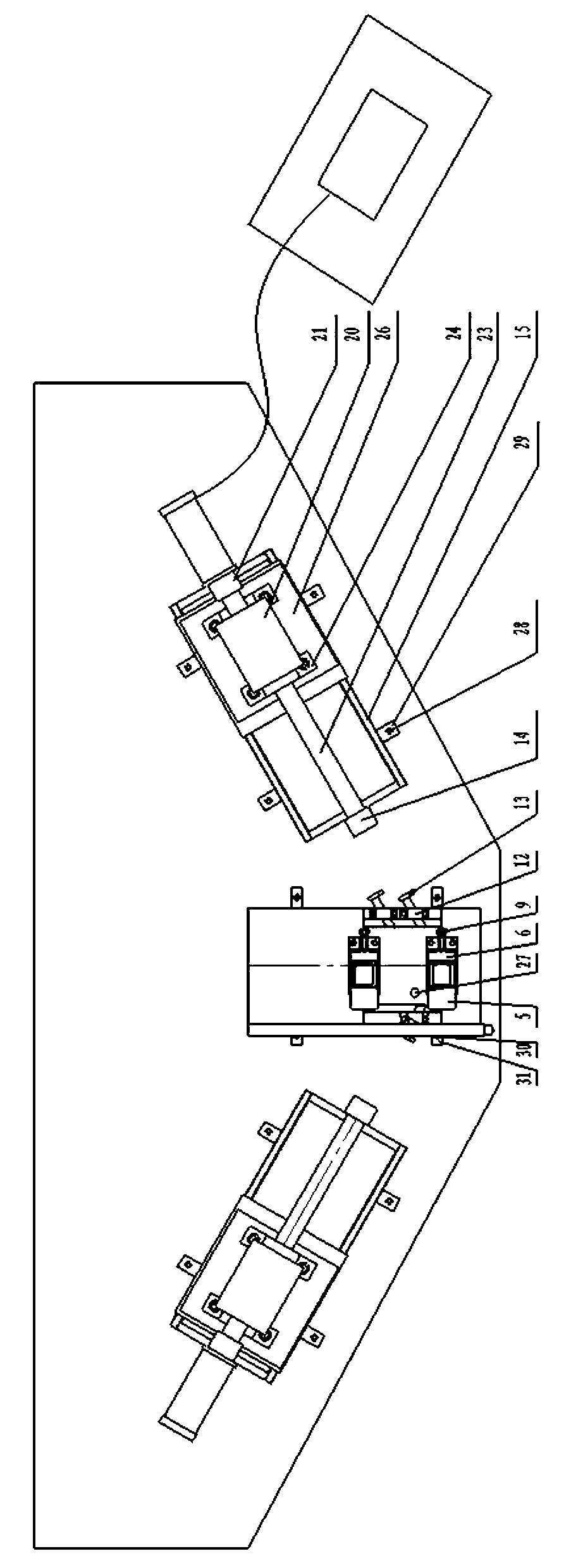

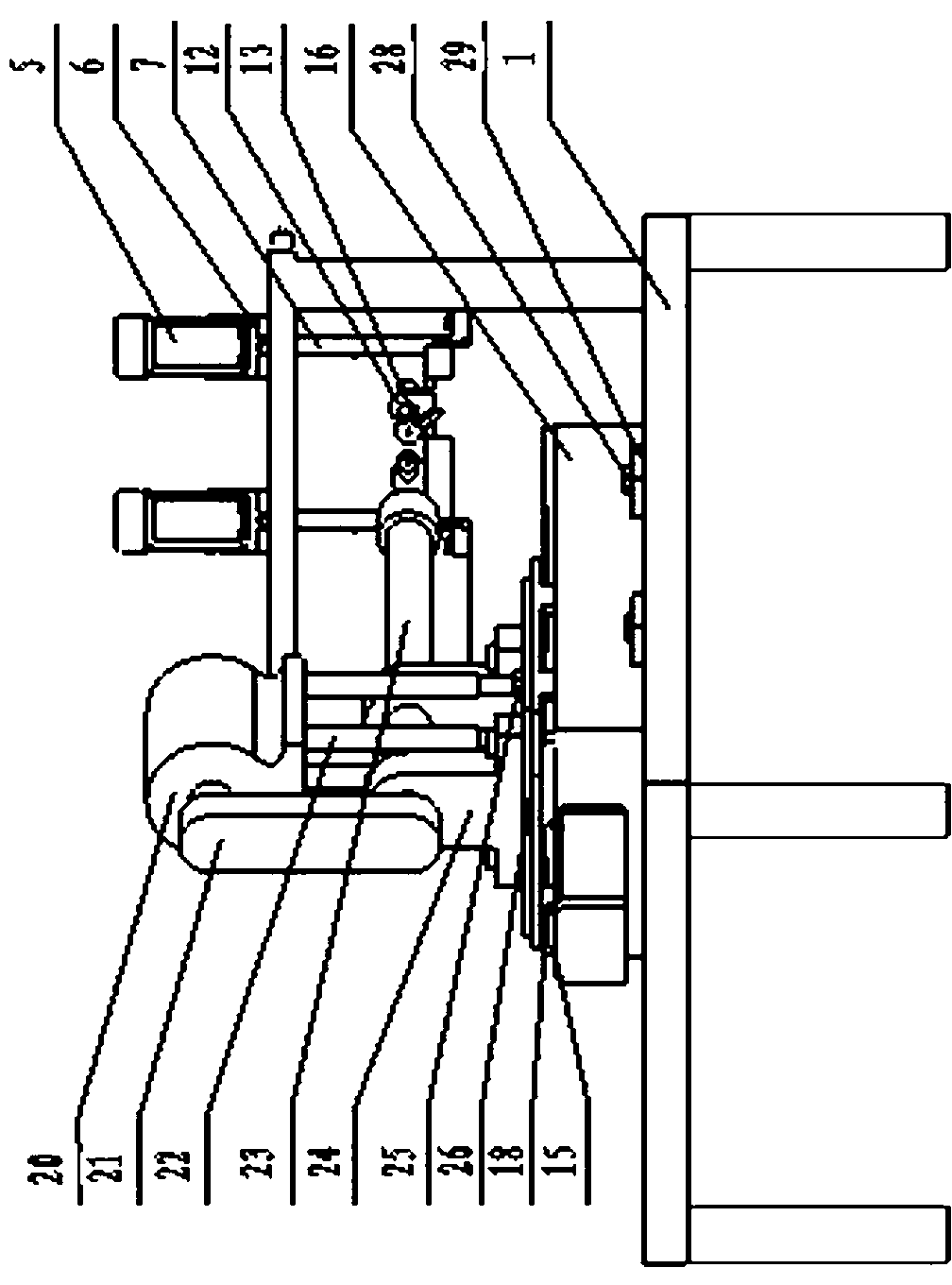

[0024] Below in conjunction with accompanying drawing, the present invention is further described:

[0025] A drilling machine for machining oblique oil holes of engine crankshafts, such as Figure 1 to Figure 3 As shown, it includes a bed 1, a clamping device 32, a drilling inclined oil hole device 33, a power supply control cabinet 2 and a numerical control cabinet 3, and the clamping device 32 and the drilling inclined oil hole device 33 are arranged on the bed 1, and the numerical control The control cabinet 3 is arranged on the power control cabinet 2, and the numerical control control cabinet 3 is connected with the drilling inclined oil hole device 33 through wires. The clamping device 32 includes a positioning plate 4, a cylinder 5, a cylinder positioning plate 6, a first stud 7, a V-shaped block 8, a tension rod 9, a second stud 10, a first nut 11, and a guide sleeve positioning Part 12 and guide sleeve 13. The guide sleeve 13 is arranged on the guide sleeve locato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com