A batch preparation method of submicron hexanitrohexaazpentazane explosive

A technology of heteroisopentazane explosives and hexanitrohexanitrogen, which is applied in explosives processing equipment, explosives, offensive equipment, etc., can solve the problems of increased post-processing difficulty, small preparation amount, long grinding time, etc., and achieves grinding time Effects of shortness, reduced handling, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

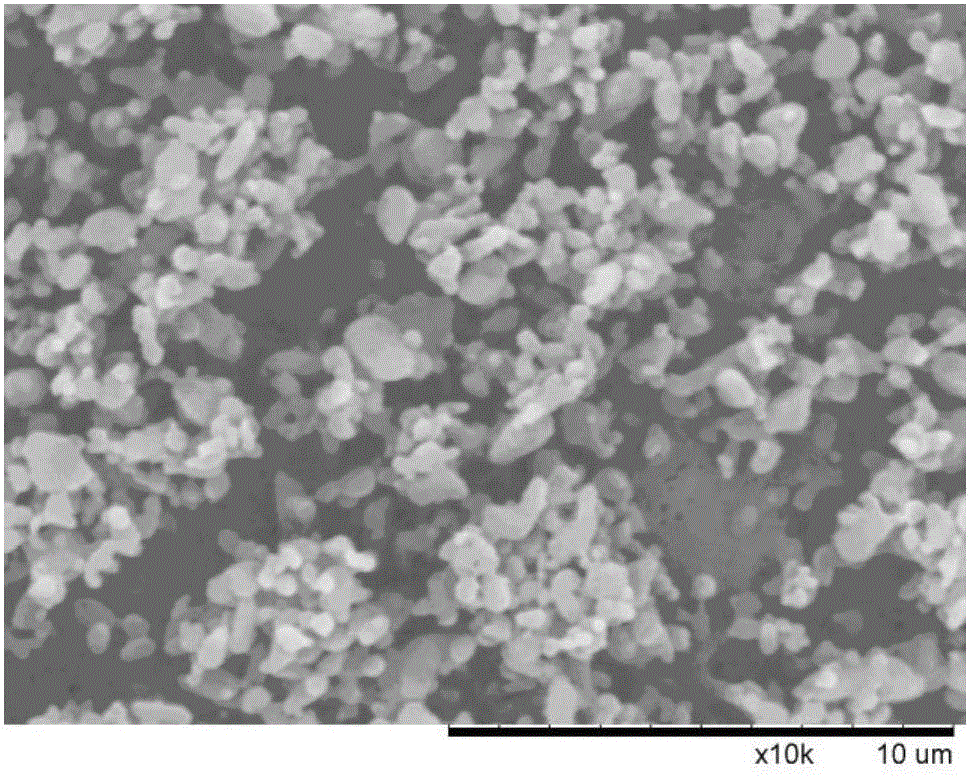

[0031] Take 0.2g of surfactant OP-10 and add it into 500g of water to make a 0.04% surfactant solution by mass percentage. Weigh two parts of the following substances: 330g of zirconia grinding balls with a diameter of 3mm, 150g of zirconia grinding balls with a diameter of 1mm, 30g of CL-20 raw materials, and 150g of surfactant solution, and add them to two grinding tanks respectively, and cool the grinding tanks to 1°C. Place the grinding jar symmetrically and fix it on the planetary grinder, start the planetary grinder, set the speed at 200rpm, take it out every hour and cool it down to 1°C, and grind for a total of 8 hours. Use a sieve to separate the ground explosive suspension from the grinding ball medium, centrifuge the separated explosive suspension at 10,000 rpm, and finally freeze-dry it at -45°C to obtain CL-20 explosive with an average particle size of 500nm .

Embodiment 2

[0033] Take 1.5g of surfactant OP-10 and add it into 500g of water to make a 0.3% surfactant solution by mass percentage. Weigh two parts of the following substances: 100g of 5mm zirconia grinding balls, 50g of ceramic grinding balls with a diameter of 1mm, 10g of CL-20 raw materials, and 25g of surfactant solution. ℃. Place the grinding tank symmetrically and fix it on the planetary grinder, start the planetary grinder, set the speed at 150rpm, take it out every hour and cool it to 5°C, and grind for 10 hours in total. Use a sieve to separate the ground explosive suspension from the grinding ball medium, filter the separated explosive suspension through a filter plate, and finally dry it in vacuum at 60°C to obtain a submicron CL-20 explosive with an average particle size of 660nm CL-20 Dynamite.

Embodiment 3

[0035] Get 4.0g of surfactant Tween-20 and add it into 2000g of water to make a 0.2% surfactant solution by mass percentage. Weigh four parts of the following substances: 1000g of zirconia grinding balls with a diameter of 3mm, 200g of tungsten carbide grinding balls with a diameter of 1mm, 100g of CL-20 raw materials, and 400g of surfactant solution. to 3°C. Place the grinding jar symmetrically and fix it on the planetary grinder, start the planetary grinder, set the speed at 200rpm, take it out every hour and cool it to 3°C, and grind for a total of 8 hours. Use a sieve to separate the ground explosive suspension from the grinding ball medium, centrifuge the separated explosive suspension at 10,000 rpm, and finally dry it in vacuum at 60°C to obtain CL-20 explosive with an average particle size of 970nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com