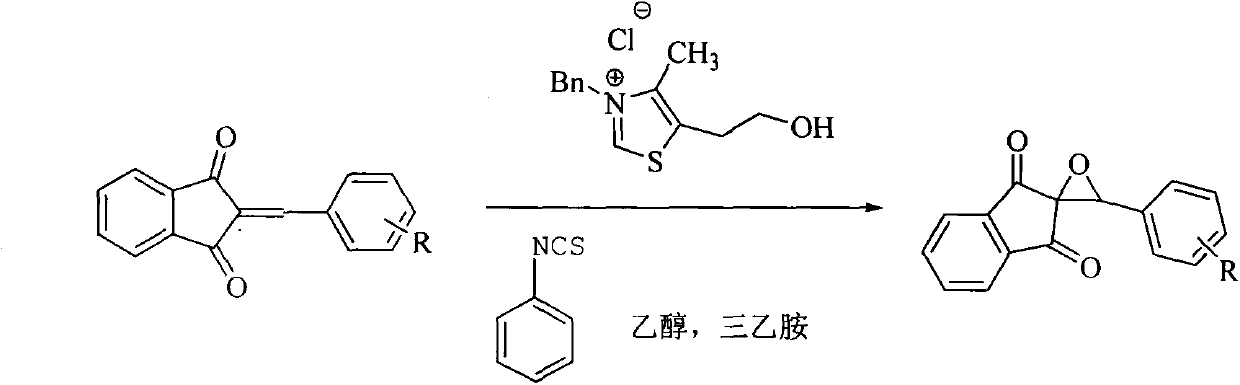

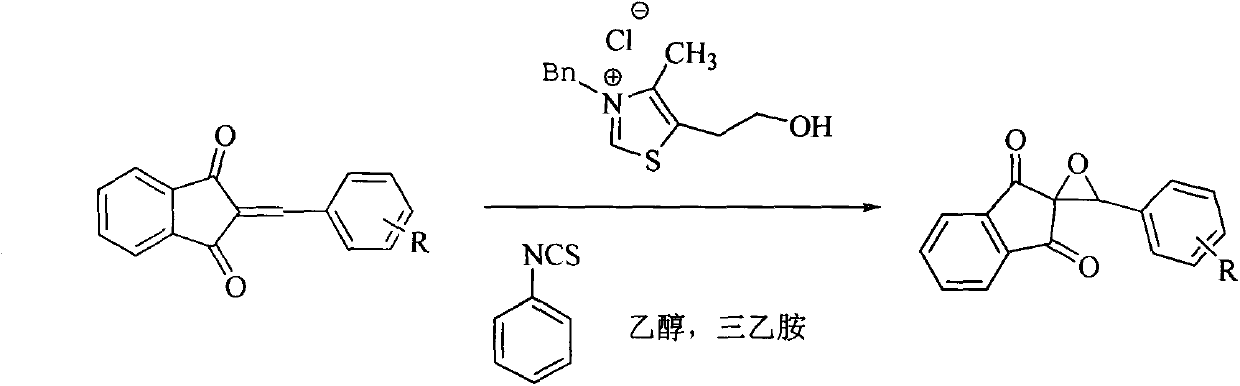

New epoxidation method of 2-benzylidene-1,3-indan diketone double bond

A technology of benzylidene and indandione, applied in the field of 2-benzylidene-1, can solve the problems of inability to synthesize epoxidation products, large damage to substrates, strong oxidation performance of hydrogen peroxide, etc., and achieves good effects , the effect of simple operation and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] 1. Reaction steps (taking the epoxidation of 2-phenylmethylene-1,3-indandione as an example):

[0014] Add 1mmol of 2-benzylidene-1,3-indandione, 0.25mmol of phenylisothiocyanate, 0.25mmol of thiazolium salt catalyst, 0.25mmol of triethylamine and 10mL of ethanol into a 50mL round bottom flask as solvent , stirred at room temperature for 30 min, evaporated most of the solvent residue and separated the product by thin layer chromatography (ethyl acetate:petroleum ether=1:4), product 227mg.

[0015] In the thin layer chromatography adopted, a mixture of cyclohexane and ethyl acetate was used as an eluent, and the mixing volume ratio of cyclohexane and ethyl acetate was 4:1.

[0016] Different epoxidized products can be obtained by substituting different substituted 2-benzylidene-1,3-indanediones for 2-benzylidene-1,3-indanediones.

[0017] General reaction formula of the present invention is:

[0018]

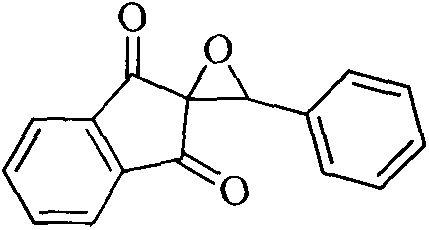

[0019] 2. Product identification:

[0020] Adopting different s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com