Vertical-type capacitor structure and manufacturing method thereof

A technology of capacitor structure and manufacturing method, which is applied in the direction of circuits, electrical components, and electrical solid devices, and can solve the problems of large resistance, high-frequency channels of multi-layer chips in three-dimensional integrated circuits, and the inability to charge groove surfaces. Achieve high capacitance density, save layout area, and improve integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0046] Specific embodiment 1: vertical shape capacitor structure and manufacturing method thereof.

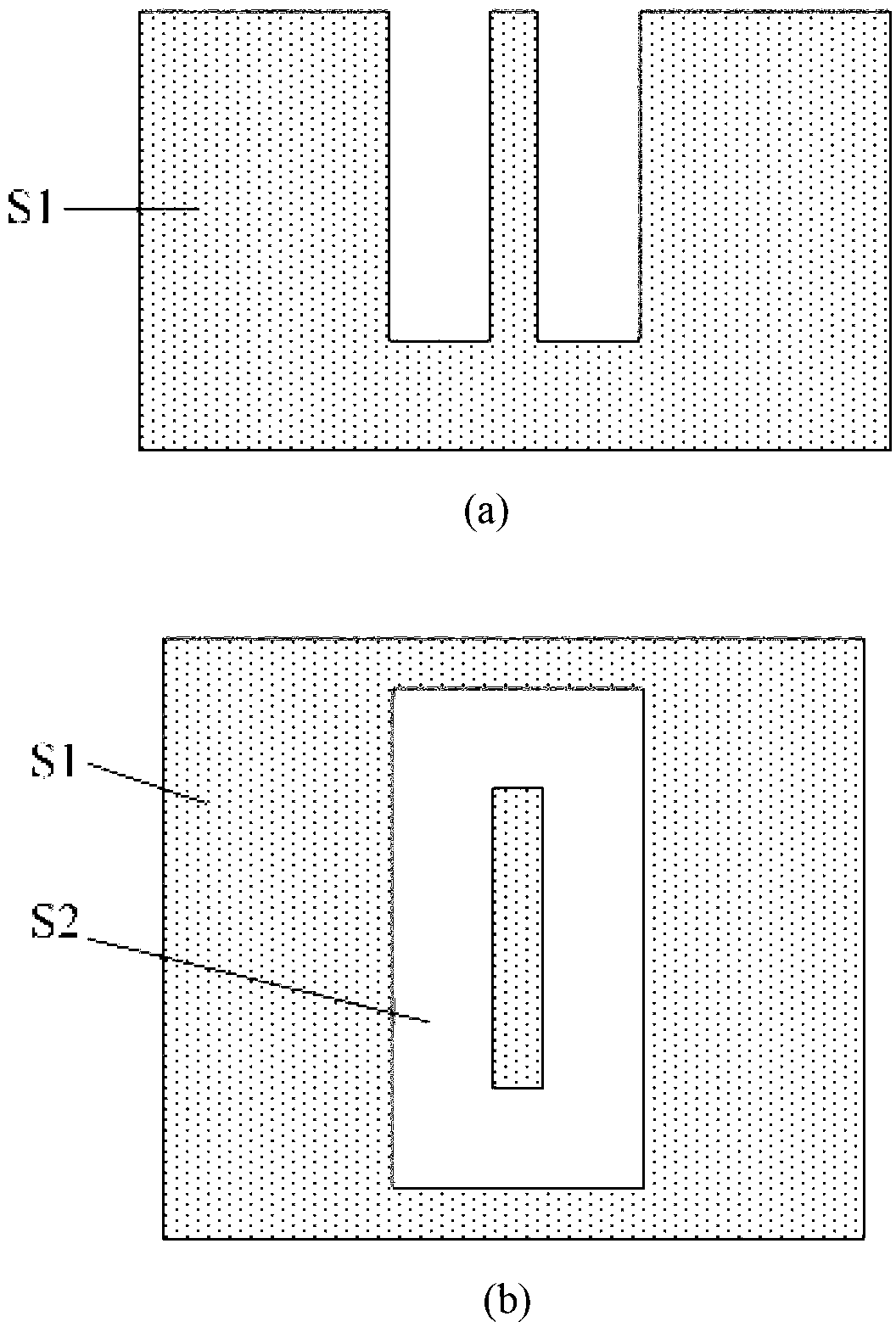

[0047] Such as figure 2 As shown, deep reactive ion etching technology is used to etch a circular deep groove S2 on the wafer substrate S1. The width of the deep trench is 5-10 microns; the length of the deep trench is not strictly limited, and can be 5-200 microns; the depth of the deep trench is less than the thickness of the wafer substrate, and can be 60-500 microns; the shape of the deep trench is One of a shape, a circular ring, or a polygonal ring.

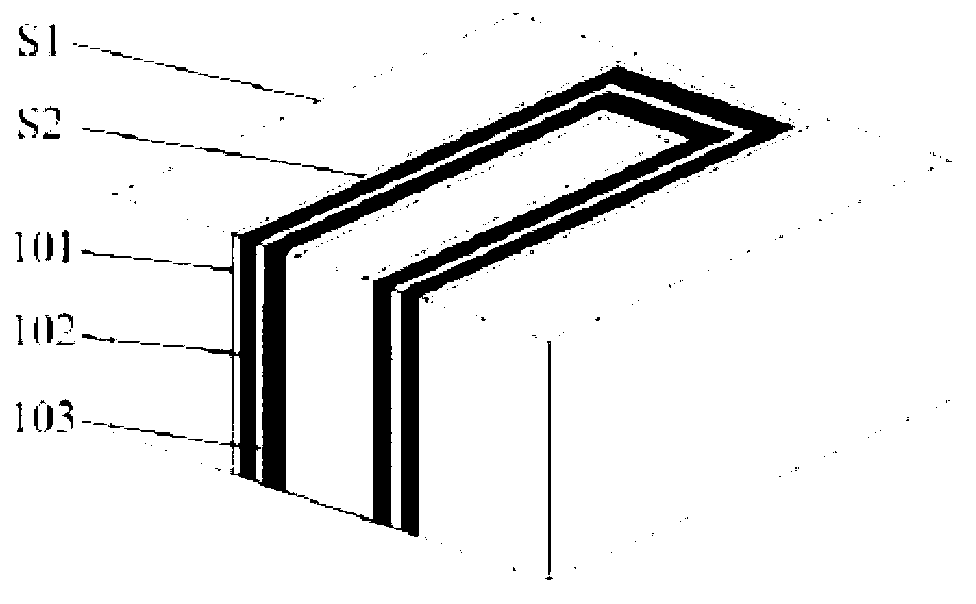

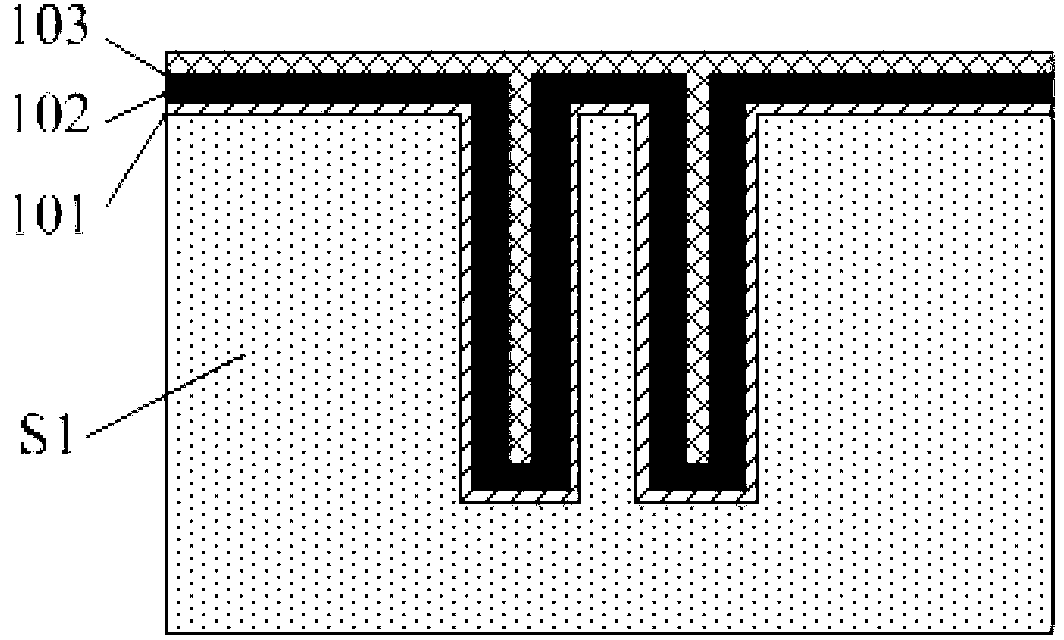

[0048] Such as image 3 As shown, the insulating layer 101 silicon dioxide is deposited on the inner wall of the deep trench by plasma enhanced chemical vapor deposition; the copper seed layer is deposited by sputtering technology, and the thickness of the copper layer is increased by electroplating to form a conductive layer 102. For inner and outer electrode plates. The thickness of the copper seed layer is not strictly...

specific Embodiment 2

[0051] Specific embodiment 2: vertical strip capacitor structure and manufacturing method thereof.

[0052] Such as Image 6 As shown, in this embodiment, the same manufacturing method as in Embodiment 1 is used to fabricate two strip-shaped deep groove structures S22 side by side. The production range of the length of the deep trench under the existing technology is 5-200 microns; the width of the deep trench in this embodiment is 3-5 microns; the depth of the deep trench is less than the thickness of the wafer substrate S21, which can be 60-500 microns; The distance between the deep grooves is 2-5 microns; the shape of the deep grooves is a rectangle or an "S" polygon.

[0053] Such as Figure 7 As shown, in this embodiment, the same manufacturing method as in Embodiment 1 is used to deposit the insulating layer 201 and deposit the conductive layer 202 in the deep trench S21 until the deep trench is filled.

[0054] Such as Figure 8 As shown, the silicon between the con...

specific Embodiment 3

[0057] Specific embodiment 3: vertical strip capacitor interdigitated parallel structure.

[0058] Such as Figure 11 As shown, this embodiment adopts the manufacturing method in Embodiment 2 to manufacture three vertical strip capacitors on the same wafer substrate, wherein 301 is an insulating layer, 302 is a conductive layer, and 303 is a dielectric layer, and then use The surface interconnection process forms the interdigitated electrodes S32 to form a parallel capacitor structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com