Lithium-ion battery negative material and preparation method thereof

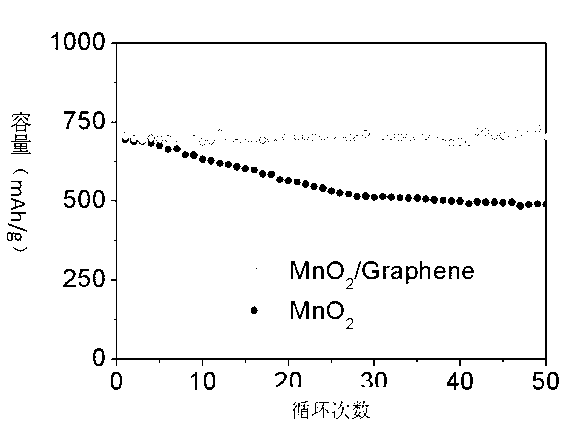

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the weak combination of metal oxides and graphene nanosheets, shorten the electron transmission path, overcome poor conductivity, and improve performance superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

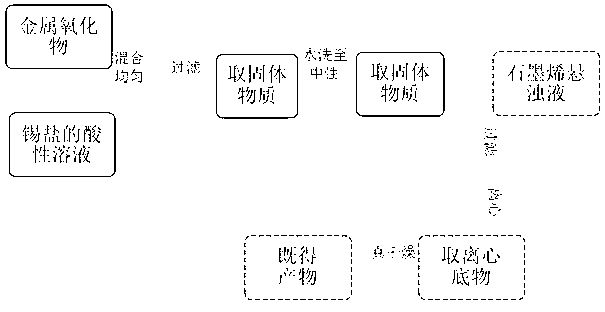

[0054] S1. Measure 2.5 milliliters of 37% concentrated hydrochloric acid and dilute to 1 liter of pH value of 1.5, then weigh 10 grams of stannous chloride and dissolve it in the above hydrochloric acid solution. Weigh 20 grams of manganese dioxide, a negative electrode material for lithium-ion batteries, and add it into the above-mentioned acidic tin chloride solution, keep the temperature at 40° C., and stir for 1 hour.

[0055] S2. Filter the above mixture, take the solid part after filtering, then add it to about 1 liter of distilled water and stir evenly, then filter, take the solid part, repeat washing 5 times, until the hydrogen ion concentration index in the distilled water after washing is measured About 7 (PH).

[0056] S3. Weigh 100 mg of graphene and add it to distilled water, set the volume to 100 ml, and then sonicate for 1 hour to obtain a suspension of graphene, and then add the solid substance treated by S2 into it and stir for 30 minutes.

[0057] S4. Use a ...

Embodiment 2

[0061] S1. Prepare 1 liter of acid aqueous solution with a pH value of 4 with nitric acid, then weigh 5 grams of stannous chloride and dissolve it in the above hydrochloric acid solution. Weigh 10 grams of manganese dioxide, a negative electrode material for lithium-ion batteries, and add it into the above-mentioned acidic tin chloride solution, keep the temperature at 30° C., and stir for 0.5 hours.

[0062] S2. Filter the above mixture, take the solid part after filtering, then add it to about 1 liter of distilled water and stir evenly, then filter, take the solid part, repeat washing 5 times, until the hydrogen ion concentration index in the distilled water after washing is measured About 7 (PH).

[0063] S3. Weigh 50 mg of graphene and add it to distilled water, set the volume to 50 ml, and then sonicate for 1 hour to obtain a suspension of graphene, then add the solid substance treated by S2 into it and stir for 10 minutes.

[0064] S4. Use a centrifuge to centrifuge sev...

Embodiment 3

[0066] S1. Take 2 milliliters of 37% concentrated hydrochloric acid and dilute to 2.5 liters, the pH value is 2, then weigh 5 grams of stannous chloride and dissolve it in the above hydrochloric acid solution. Weigh 20 grams of nickel oxide, a lithium-ion battery negative electrode material, and add it into the above-mentioned acidic tin chloride solution, and stir in a water bath with a constant temperature of 40° C. for 1 hour.

[0067] S2. Filter the above mixture, take the solid part after filtering, then add it to about 1 liter of distilled water and stir evenly, then filter, take the solid part, repeat washing 5 times, and measure the hydrogen ion concentration index of the lotion to be about 7 (PH).

[0068] S3. Weigh 100 mg of graphene and add it to distilled water, set the volume to 100 ml, and then sonicate for 1 hour to obtain a suspension of graphene, and then add the solid substance treated by S2 into it and stir for 30 minutes.

[0069] S4. Use a centrifuge to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com