Catalyst for preparing halogenated aniline through catalytic hydrogenation of halogenated nitrobenzene and application thereof

A technology for halogenated nitrobenzene and halogenated aniline production, which is applied in the field of catalysts for halogenated nitrobenzene catalytic hydrogenation to produce halogenated aniline, and can solve the problems of high production cost, difficult catalyst recovery, and expensive carbon nanotubes. , to achieve the effect of easy separation, easy solid-liquid separation, and inhibition of dechlorination side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

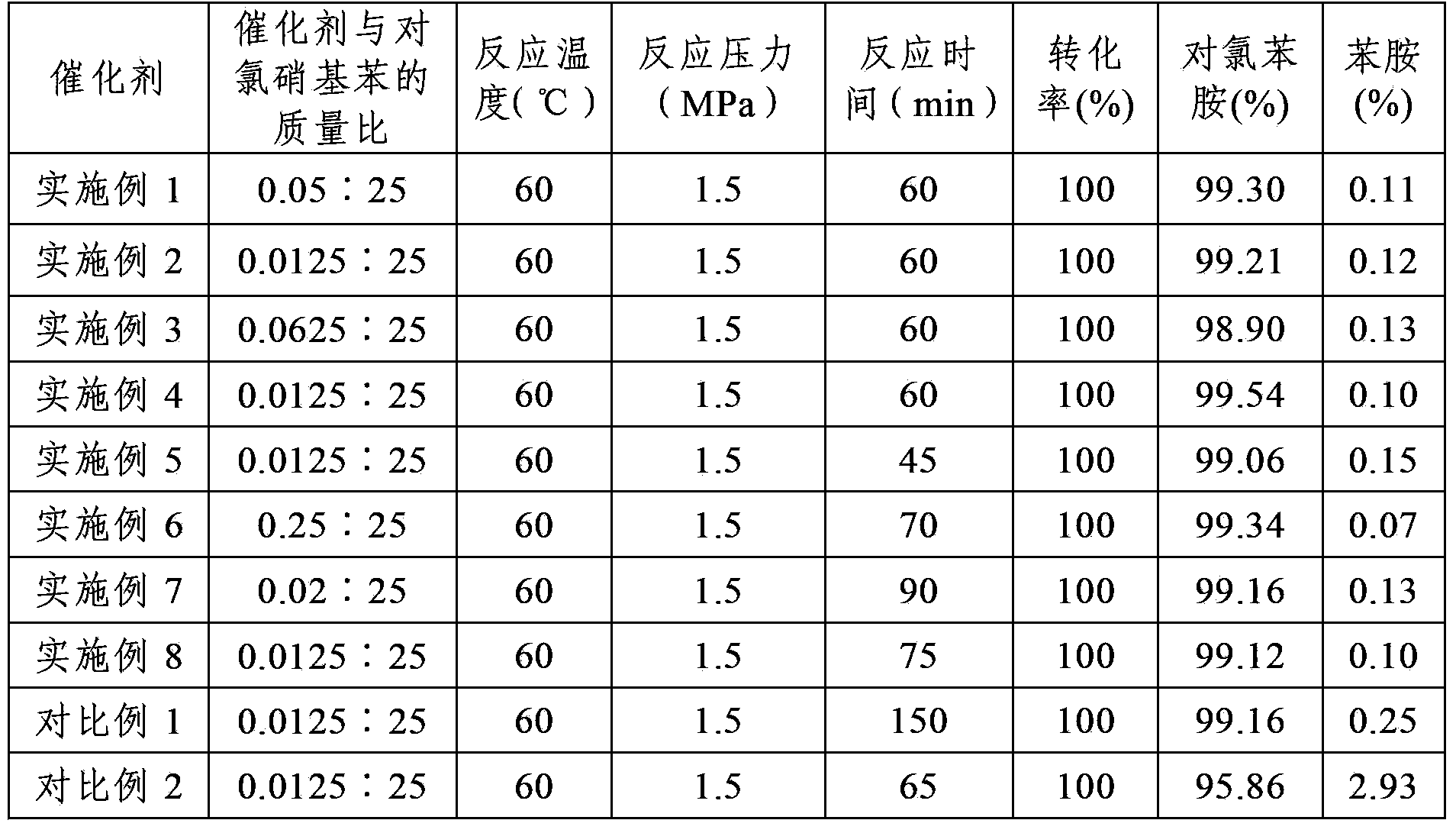

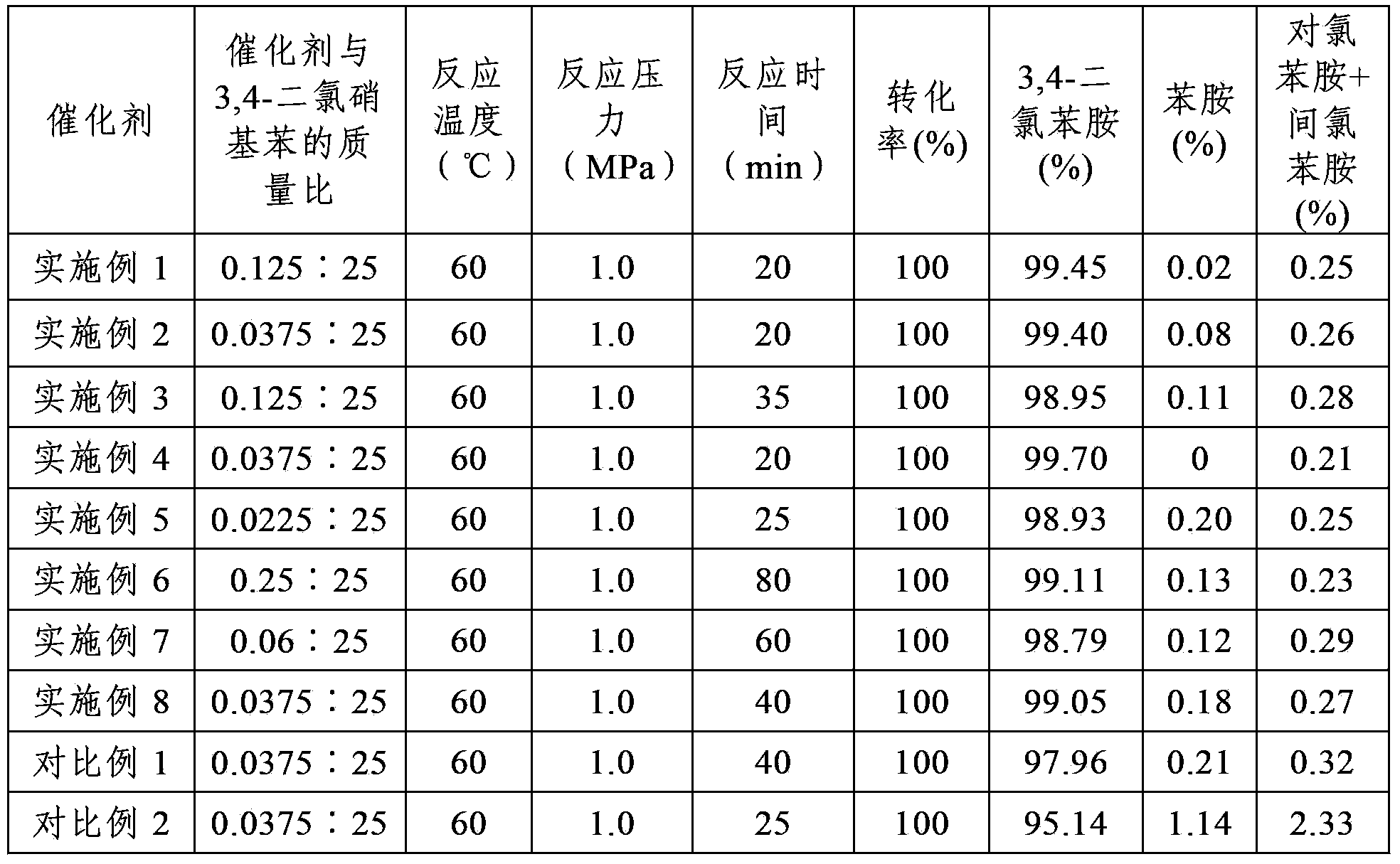

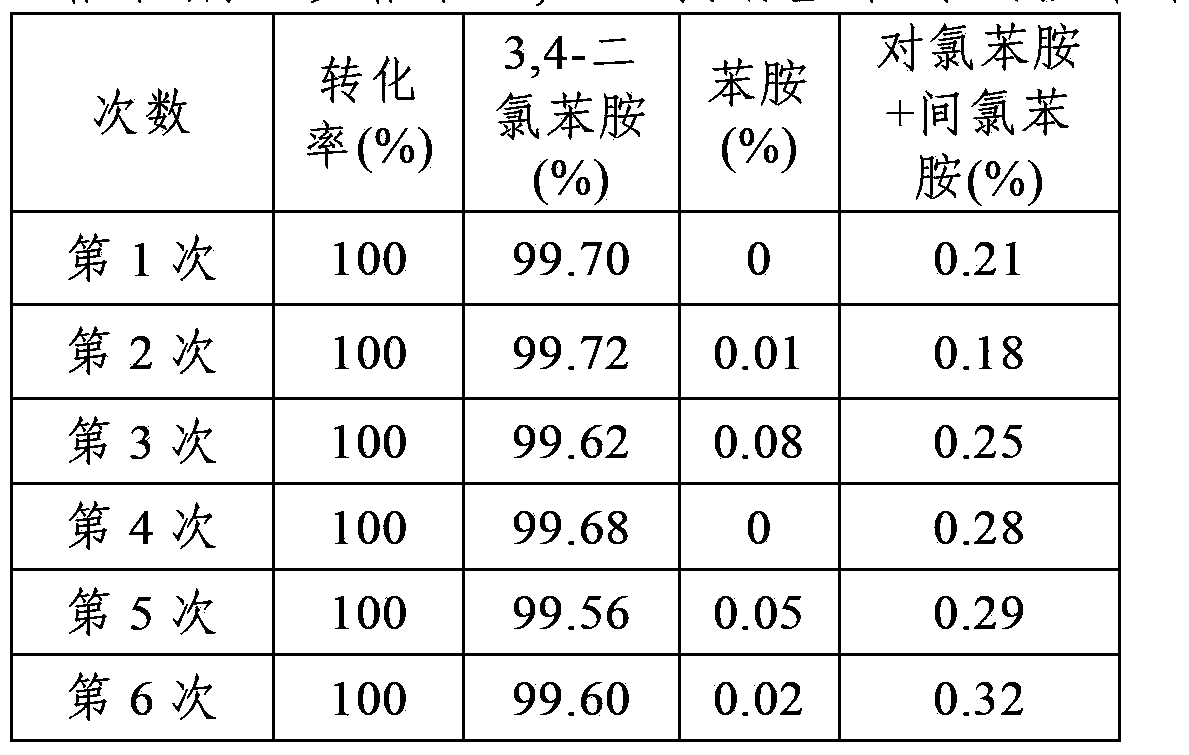

Examples

Embodiment 1

[0026] Step 1, the specific surface area of 10g is 1200m 2 / g of activated carbon was treated with nitric acid with a mass concentration of 15% at 100°C for 2 hours, then washed with water to neutrality, and dried for later use;

[0027] Step 2. Place 9.9 g of activated carbon dried in step 1 in an aqueous solution of sodium carbonate with a mass concentration of 0.05%, and soak for 0.5 h at a temperature of 60° C.;

[0028] Step three, put H 2 PtCl 6 Dissolve in water to obtain an active component solution with a platinum content of 0.05 g / mL;

[0029] Step 4. Under the condition that the temperature is 80°C, add 2 mL of the active component solution described in Step 3 dropwise to the aqueous sodium carbonate solution impregnated with activated carbon in Step 2. After the addition is completed, keep warm and soak for 2 hours, and then use a mass concentration of 5% NaOH solution adjusts the pH value of the system to 9.0, filters after cooling, and obtains a filter cake;...

Embodiment 2

[0032] Step 1, the specific surface area of 10g is 1500m 2 / g of activated carbon was treated with nitric acid with a mass concentration of 30% at 90°C for 1 h, then washed with water to neutrality, and dried for later use;

[0033] Step 2. Place 9.7 g of activated carbon dried in step 1 in an aqueous solution of sodium carbonate with a mass concentration of 0.25%, and soak for 0.5 h at a temperature of 70° C.;

[0034] Step three, put H 2 PtCl 6 Dissolve in water to obtain an active component solution with a platinum content of 0.05 g / mL;

[0035]Step 4. Under the condition that the temperature is 70°C, add 6 mL of the active component solution described in Step 3 dropwise to the aqueous sodium carbonate solution impregnated with activated carbon in Step 2. After the addition is completed, keep warm and soak for 3 hours, and then use a mass concentration of 5% KOH solution adjusted the pH value of the system to 9.0, filtered after cooling to obtain a filter cake;

[003...

Embodiment 3

[0038] Step 1, the specific surface area of 10g is 800m 2 1 / g of activated carbon was treated with hydrochloric acid with a mass concentration of 5% at 90°C for 3 hours, then with nitric acid with a mass concentration of 15% at 90°C for 2 hours, washed with water until neutral, and dried for later use;

[0039] Step 2. Place 9.9 g of activated carbon dried in step 1 in an aqueous solution of potassium carbonate with a mass concentration of 0.01%, and soak for 5 hours at a temperature of 20° C.;

[0040] Step three, put H 2 PtCl 6 Dissolve in water to obtain an active component solution with a platinum content of 0.05 g / mL;

[0041] Step 4. Under the condition that the temperature is 80°C, add 2 mL of the active component solution described in Step 3 dropwise to the aqueous sodium carbonate solution impregnated with activated carbon in Step 2. After the addition is completed, keep warm and soak for 1 hour, and then use a mass concentration of 5% KOH solution adjusted the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com