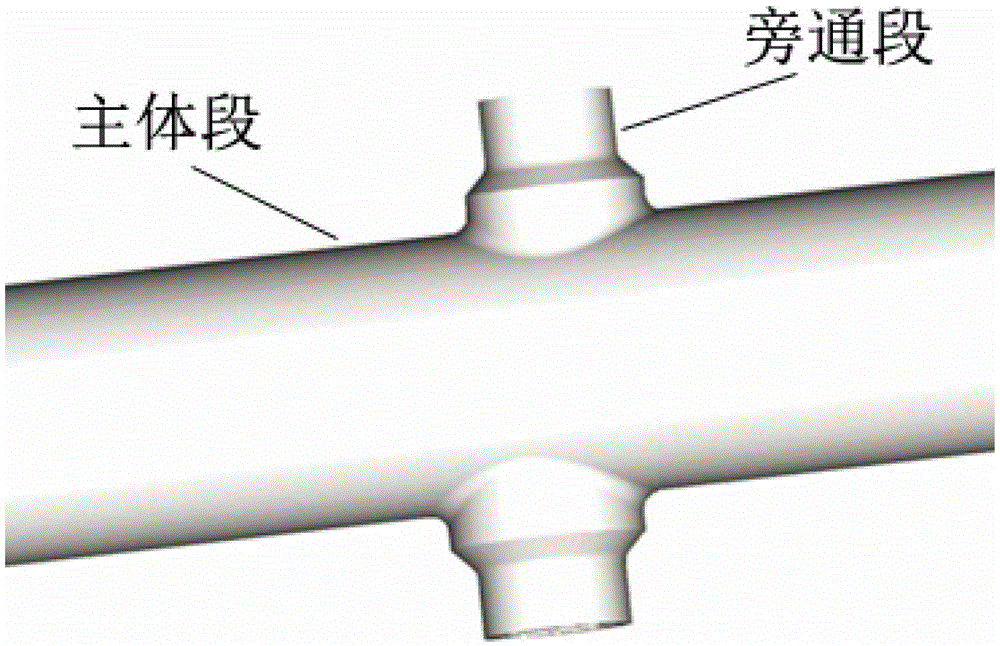

A production method of austenitic stainless steel special-shaped integral large forging

A technology for austenitic stainless steel and large forgings, applied in the field of stainless steel processing, can solve problems such as grain size control, achieve the effects of refining the structure of forgings, inhibiting abnormal growth, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1: Effects of electroslag ingot surface grinding and forging blanking on the thermal processing performance of steel ingots

[0054]The 3# electroslag ingot has not undergone surface grinding and forging blanking, and is directly heated at 1220 ° C for upsetting. The upsetting deformation ratio is 1.7:1, and serious cracks appear in the steel ingot; 2# electroslag ingot has not undergone surface grinding , heated at 1180°C for 11% deformation of the billet forging, and then returned to the furnace to heat upsetting at 1220°C, the upsetting deformation ratio was 1.9:1, and no cracks appeared; after surface grinding of 9# electroslag ingot, it was It was heated at 17% for open billet forging, and then returned to the furnace at 1220°C for upsetting. The upsetting deformation ratio was 2.8:1, and no cracks appeared. The results show that the surface grinding of electroslag ingot and forging billet can improve the hot workability of steel ingot.

Embodiment 2

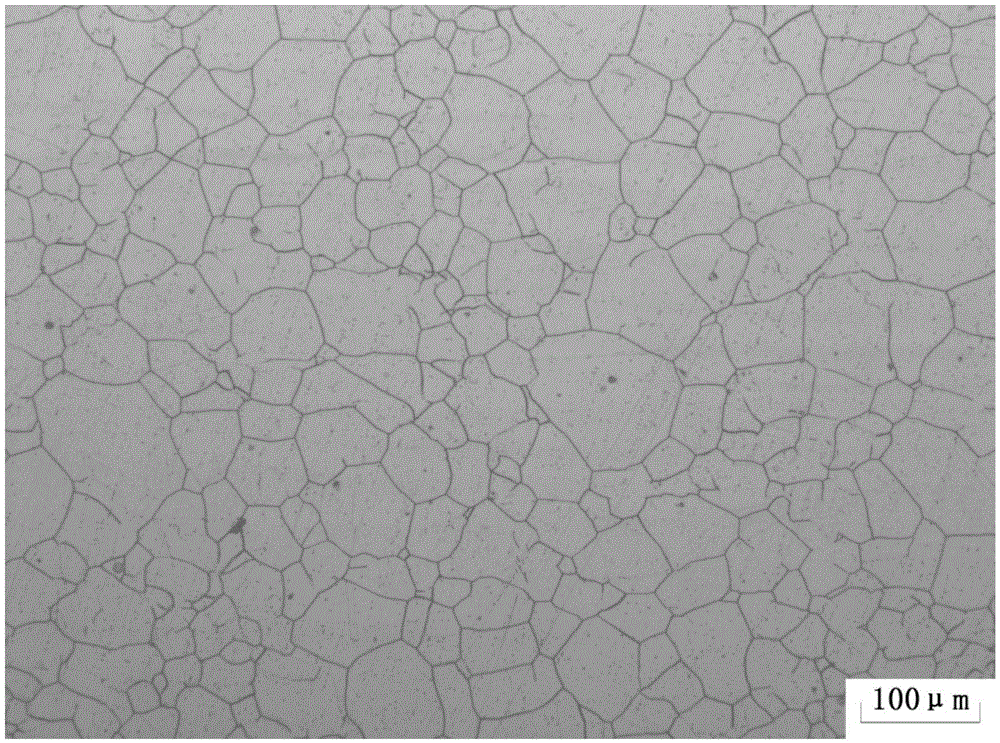

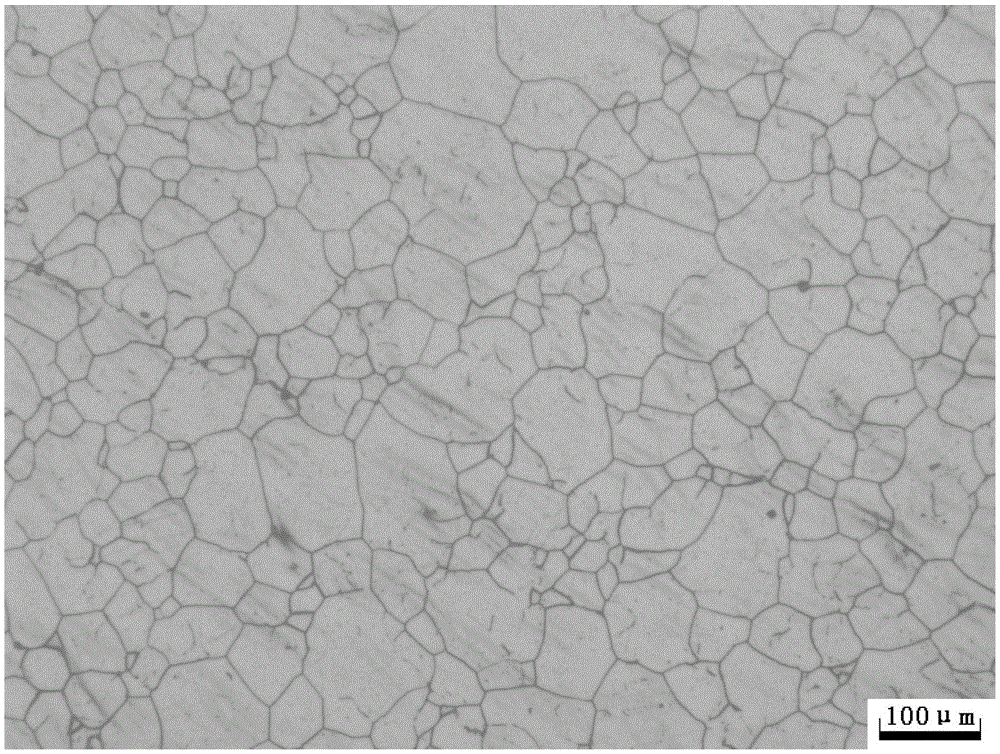

[0055] Example 2: Influence of upsetting and elongation with large amount of deformation on the grain size of special-shaped forgings

[0056] The upsetting deformation ratio of the 7# forging is 1.5:1, and the grain size of the special-shaped forging is 3.5 (attached Figure 4 ), the upsetting deformation ratio of 2# forging is 1.9:1, and the grain size reaches 4.5 grades (attached image 3 ); the upsetting deformation ratio of 1# forging is 2.3:1, and the grain size reaches grade 5.0 (attached figure 2 ). The results show that increasing the upsetting deformation ratio can refine the grain size of forgings. Example 3: Influence of integral forging return heating temperature and deformation amount on the grain size of special-shaped forgings

Embodiment 3

[0057] The upsetting deformation ratio of 8# forging and 1# forging is basically the same, 2.2:1 and 2.3:1 respectively. The main difference is that the overall forging heating temperature and deformation are different. The heating temperature of the 8# forging is 1180°C, the deformation is 15%, and the grain size is 2.5 (attached Figure 5 ); the heating temperature of 1# forging is 1120°C, the deformation is 30%, and the grain size is 5.0 (attached figure 2 ). The results show that reducing the reheating temperature and increasing the forging deformation can refine the grain size of the forging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com