Novel wet flue gas desulfurization wastewater treatment method and system

A wet flue gas desulfurization and wastewater treatment technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The problem of high cost can reduce operation and maintenance costs and equipment investment, reduce a large amount of sludge discharge, and reduce the amount of system operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

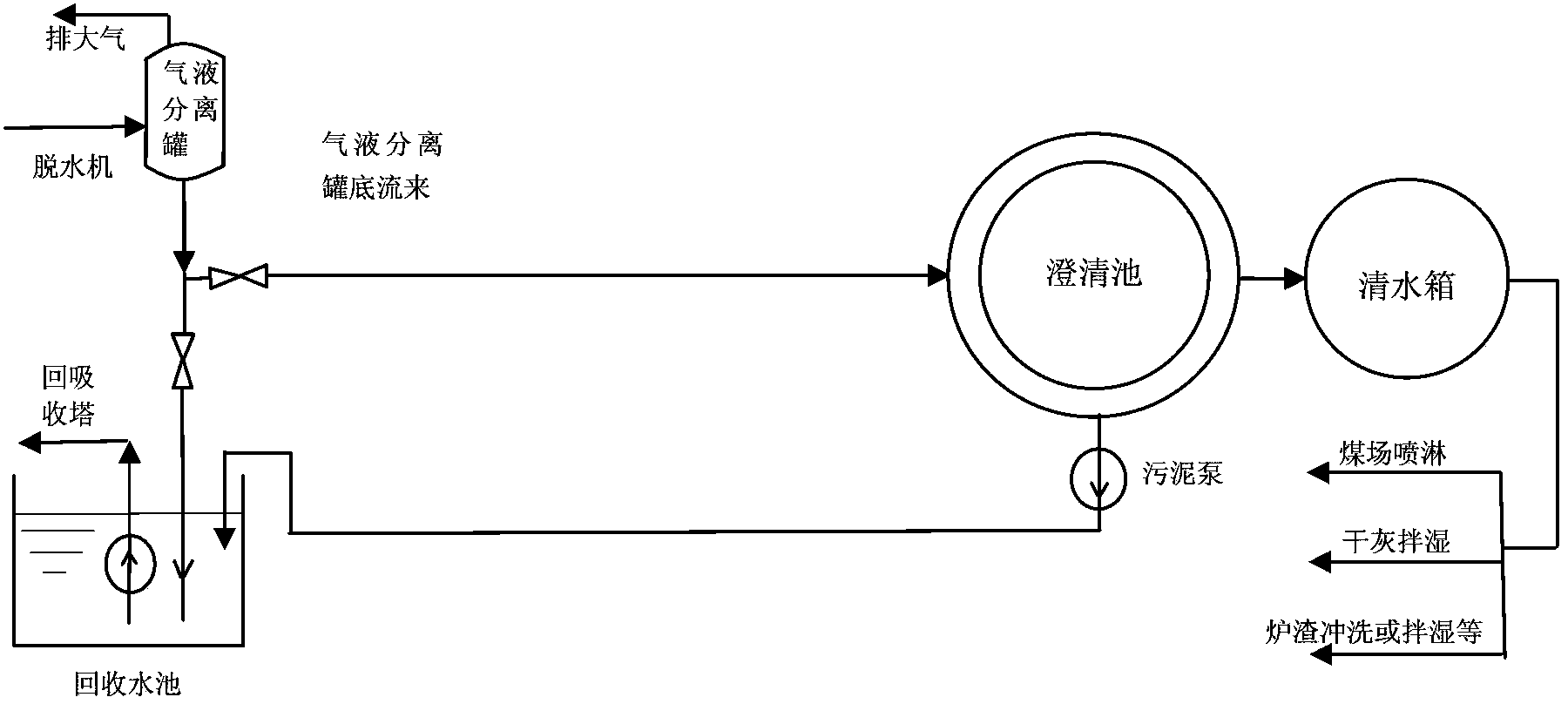

[0058] Such as image 3 As shown, this embodiment provides a 2×600MW coal-fired generating unit wet desulfurization wastewater treatment system, the overflow of the gypsum cyclone returns to the recovery pool, and the underflow of the gypsum cyclone is concentrated gypsum slurry, which is transported to the vacuum belt The dehydrator and the gas-liquid separation tank are the main suction equipment of the vacuum belt dehydrator, which are used to suck the water in the gypsum slurry through the filter cloth. The sucked desulfurization wastewater enters the gas-liquid separation tank of the vacuum belt conveyor. The desulfurization wastewater from the bottom flow of the gas-liquid separation tank, such as Figure 6 and Figure 7 As shown, its solid content rate is about 0.05%, which is greatly reduced compared with the solid content rate of 1% in the desulfurization wastewater separated by the wastewater cyclone of the traditional treatment system.

[0059] The maximum waste ...

Embodiment 2

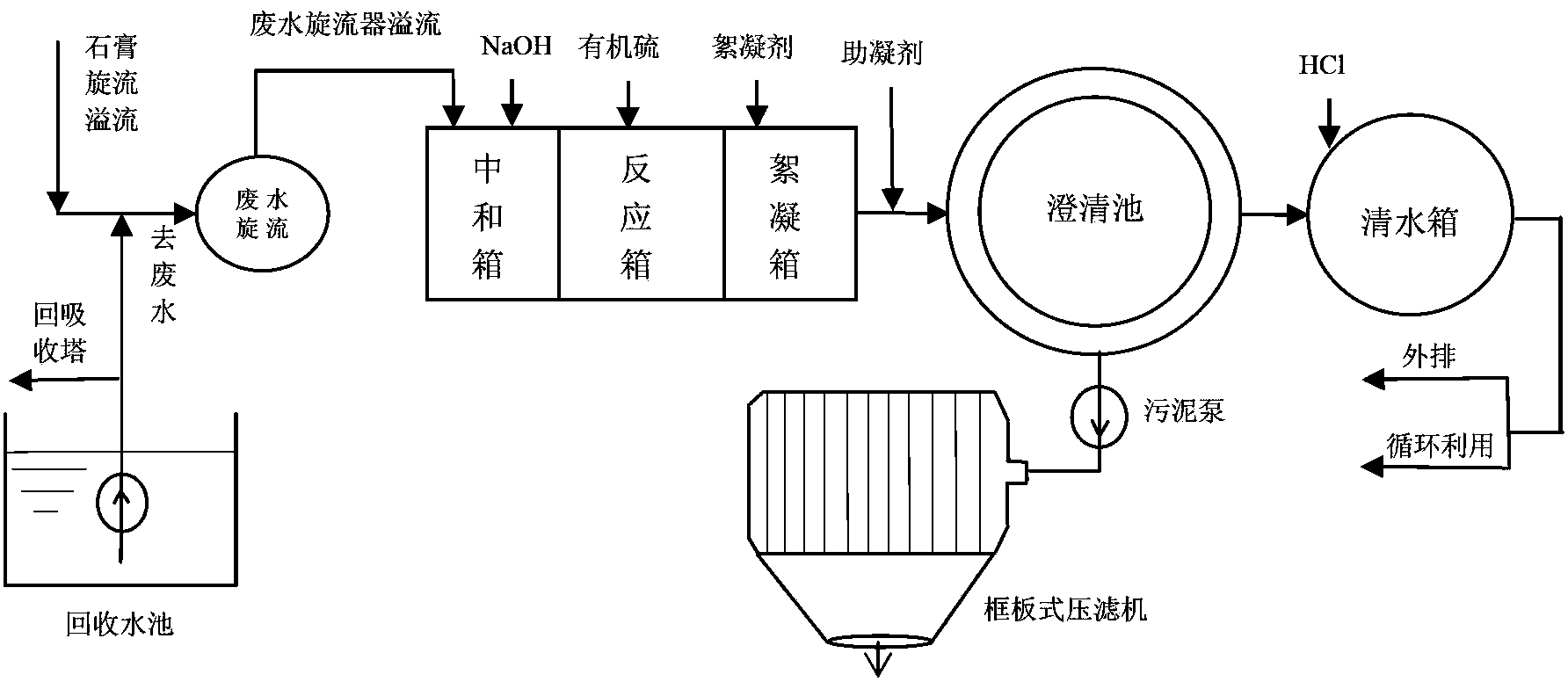

[0066] Such as Figure 4 As shown, this embodiment provides a 2×600MW coal-fired generating set wet desulfurization wastewater treatment system. On the basis of Embodiment 1, a waste water triple tank is added. The waste water triple tank includes a neutralization tank, a reaction tank and Flocculation box. Desulfurization wastewater can be settled in three stages in the wastewater triple tank to further reduce the solid content. In addition, there is another benefit: some enterprises have very strict requirements on wastewater, or the factory cannot be recycled and needs to be discharged. At this time The waste water triple box can add a dosing device at any time, which improves the flexibility of the system.

[0067] The system of this embodiment also adds a waste water triple tank bypass, and the connection and closure of the waste water triple tank bypass is controlled by a valve. This ensures the flexibility and reliability of the system, and ensures the long-term, stab...

Embodiment 3

[0069] Such as Figure 5 As shown, this embodiment provides a 2×600MW coal-fired generating set wet desulfurization wastewater treatment system. On the basis of Embodiment 2, the dosing device of the wastewater triple tank, the clarifier tank and the clean water tank is added, and as the sewage Frame plate filter press for mud pressing equipment.

[0070] After the desulfurization wastewater enters the neutralization tank, the pH value is 5.0-6.0. In order to remove heavy metals in the desulfurization wastewater, NaOH or Ca(OH)2 is added to increase the pH value to 9.0±0.5. At this time, Cu, Cr, Pb and other heavy metals are The hydroxide form is basically precipitated, and the remaining heavy metals are captured by organic sulfur in the reaction box to form a fine suspension. The suspended solids are interconnected and enlarged under the contact and wrapping of the flocculant, and continue to grow through the action of the polyacrylamide (PAM) coagulant. After entering the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com