A kind of biodiesel lubricant for water-based drilling fluid and its preparation method and application

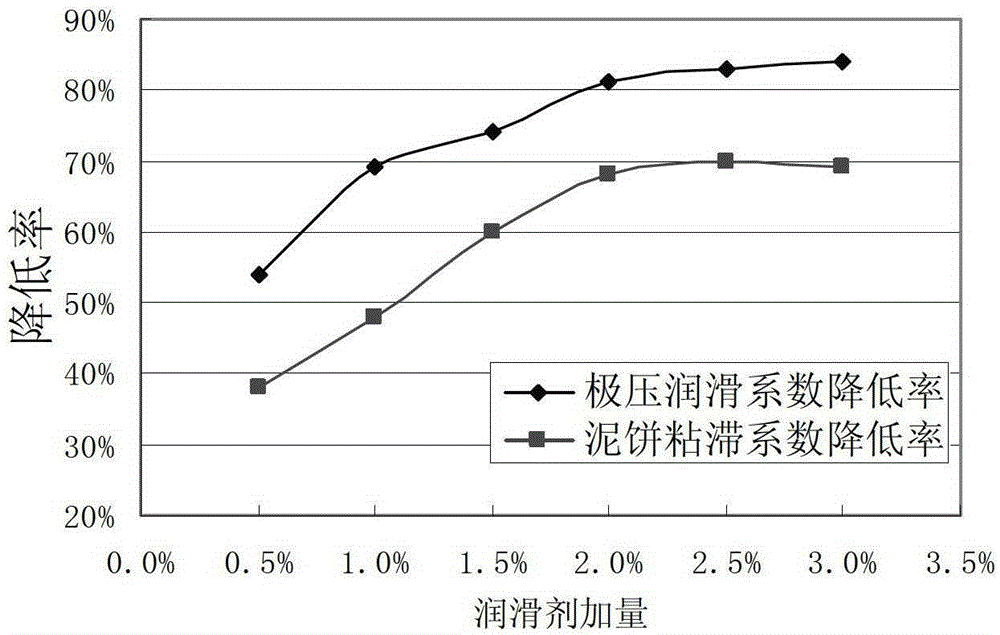

A technology of water-based drilling fluid and biodiesel, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of not meeting the requirements of lubricant temperature resistance, affecting the biodegradability of lubricants, and affecting the function of lubricants Effect and other issues, to achieve the effect of good compatibility, good synergy, and reduce friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The formula of the lubricant of the present embodiment:

[0051] 80 parts by weight of biodiesel;

[0052] 20 parts by weight of water;

[0053] Based on the total weight of biodiesel and water as 100%:

[0054]

[0055] The preparation method of the lubricant of the present embodiment is as follows:

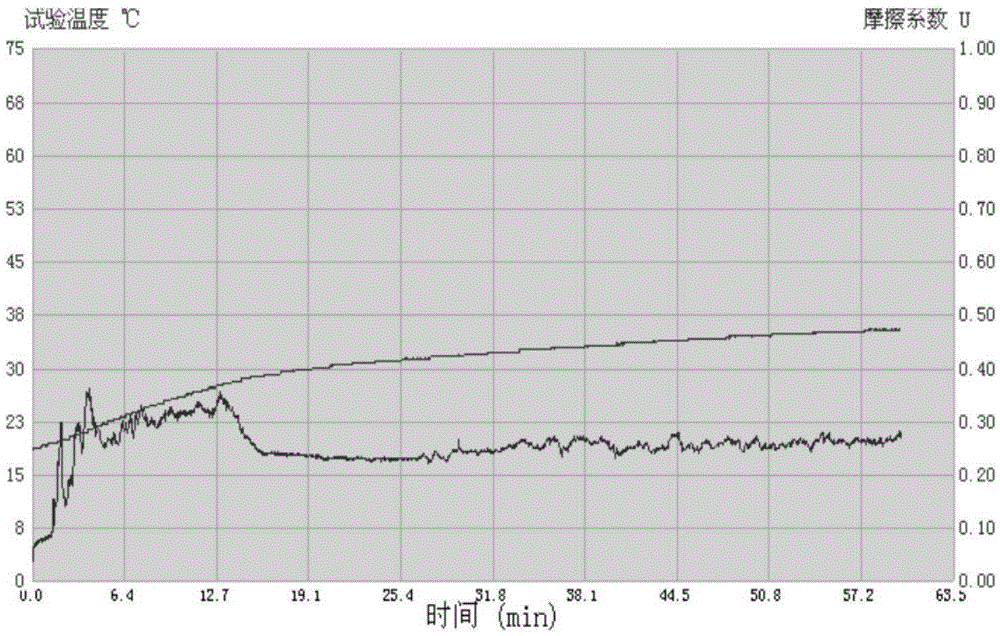

[0056] Add 3g of phosphate ester extreme pressure lubricant (the phosphate ester was purchased from KNAO Trading (Shanghai) Co., Ltd., product model S-830), 2g of Span80 lipophilic emulsifier, and 2g of graphite solid lubricant into 80g of fatty acid methyl ester In biodiesel, stir for 1 hour at room temperature and at a speed of 400 r / min to obtain an oil phase;

[0057] Add 2g of Tween80 hydrophilic emulsifier into 20g of water, stir evenly to form a solution, then add 0.1g of sodium carboxymethylcellulose dispersant, stir until completely dissolved, and obtain an aqueous phase;

[0058] Add the prepared water phase to the stirred oil phase, stir for 6 hours at a...

Embodiment 2

[0075] The formula of the lubricant of the present embodiment:

[0076] 75 parts by weight of biodiesel;

[0077] 25 parts by weight of water;

[0078] Based on the total weight of biodiesel and water as 100%:

[0079]

[0080] The preparation method of the lubricant of the present embodiment is as follows:

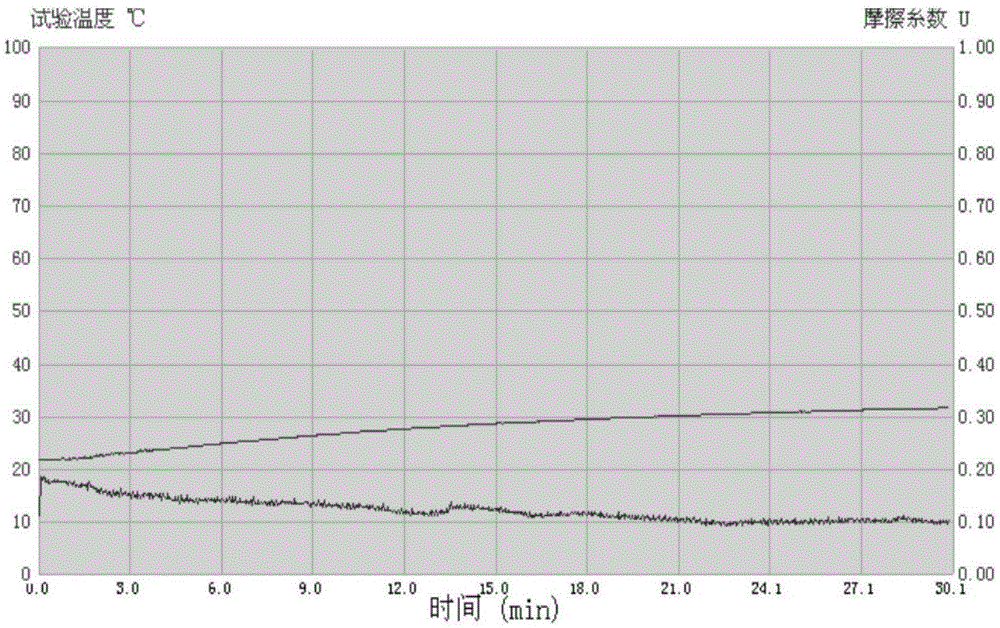

[0081] Add 5g of phosphate ester extreme pressure lubricant (the phosphate ester was purchased from KNAO Trading (Shanghai) Co., Ltd., product model S-830), 3g of Span80 lipophilic emulsifier, and 3g of graphite solid lubricant into 75g of fatty acid methyl ester In biodiesel, stir for 1.5h at room temperature and at a speed of 800r / min to obtain an oil phase;

[0082] Add 4g of Tween80 hydrophilic emulsifier into 25g of water, stir evenly to form a solution, then add 0.2g of sodium carboxymethylcellulose dispersant, stir until completely dissolved, and obtain an aqueous phase;

[0083] The prepared water phase was added to the stirred oil phase, stirred for 5 hour...

Embodiment 3

[0091] The formula of the lubricant of the present embodiment:

[0092] 70 parts by weight of biodiesel;

[0093] 30 parts by weight of water;

[0094] Based on the total weight of biodiesel and water as 100%:

[0095]

[0096] The preparation method of the lubricant of the present embodiment is as follows:

[0097] Add 1g of oil-soluble boron nitride (purchased from Ningxia Dongke Petrochemical Co., Ltd., product model T391), 1g of Span80 lipophilic emulsifier, and 1g of graphite solid lubricant to 70g of fatty acid methyl ester biodiesel, at room temperature and at a speed of 600r / Stir for 1 h under the condition of min to obtain the oil phase;

[0098] Add 2g of Tween80 hydrophilic emulsifier into 30g of water, stir evenly to form a solution, then add 0.3g of sodium carboxymethylcellulose dispersant, stir until completely dissolved, and obtain an aqueous phase;

[0099] The prepared water phase was added to the stirred oil phase, stirred for 3 hours at a temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com