Method and device of cleaning microparticles on surface of metal workpiece with laser shock waves

A metal workpiece and shock wave technology, applied in the field of laser cleaning, can solve the problems of low cleanliness, easy damage to the surface, contamination of the substrate, etc., to achieve the effect of improving mechanical properties, preventing secondary pollution, and avoiding burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

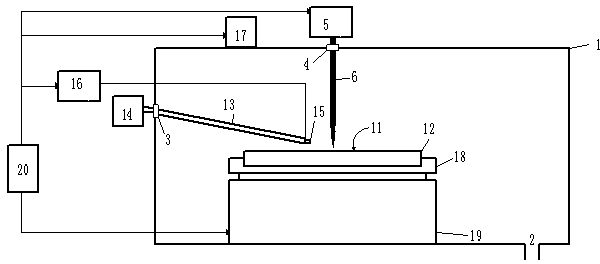

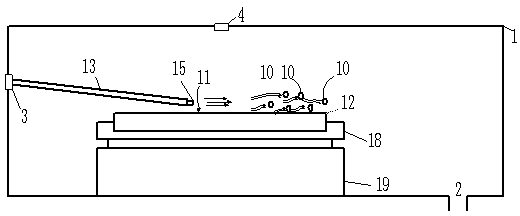

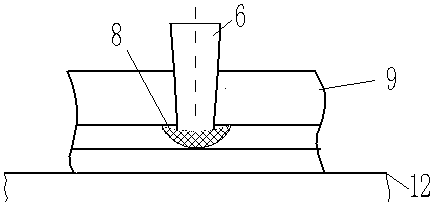

[0042] In order to better explain the details of the implementation of the present invention, a laser shock wave cleaning device and working method of the present invention for microparticles on the surface of metal workpieces will be described in detail below in conjunction with the accompanying drawings.

[0043] figure 1 Shown is a laser shock wave cleaning device for fine particles on the surface of metal workpieces, including cleaning chamber 1, water pipe window 3, laser window 4, drain outlet 2, computer control module 20, pulse laser 5, chuck 18, electric control platform 19, monitoring Module 17, metal workpiece surface 11, metal workpiece 12, water tank 14, stainless steel pipe 13, flat nozzle 15, water flow control module 16;

[0044] In the cleaning room 1, the chuck 18 on the electric control platform 19 is used to horizontally fix the metal workpiece 12 on the electric control platform 19, and the drain outlet 2 on the bottom surface of the cleaning room 1 is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Pulse energy | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com