Hydrothermal preparation method of CU2ZnSnS4, CU2ZnSnS4 material and application thereof

A hydrothermal, selected technology, applied in chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve the problem that compounds are difficult to obtain pure and equal, and achieve the effects of low production cost, easy size control, and optimized conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] (1) Express the amount of substance in millimoles, add copper acetate, zinc acetate, tin chloride and ascorbic acid and thioacetamide to 50ml polytetrafluoroethylene respectively in the millimole ratio of 2:1:1:2:40 In the ethylene reactor, then add 40ml of water, stir, ultrasonically dissolve, to be made into the solution that concentration is 0.02M (mol / liter), wherein, ascorbic acid is reducing agent; Thioacetamide is sulfur source;

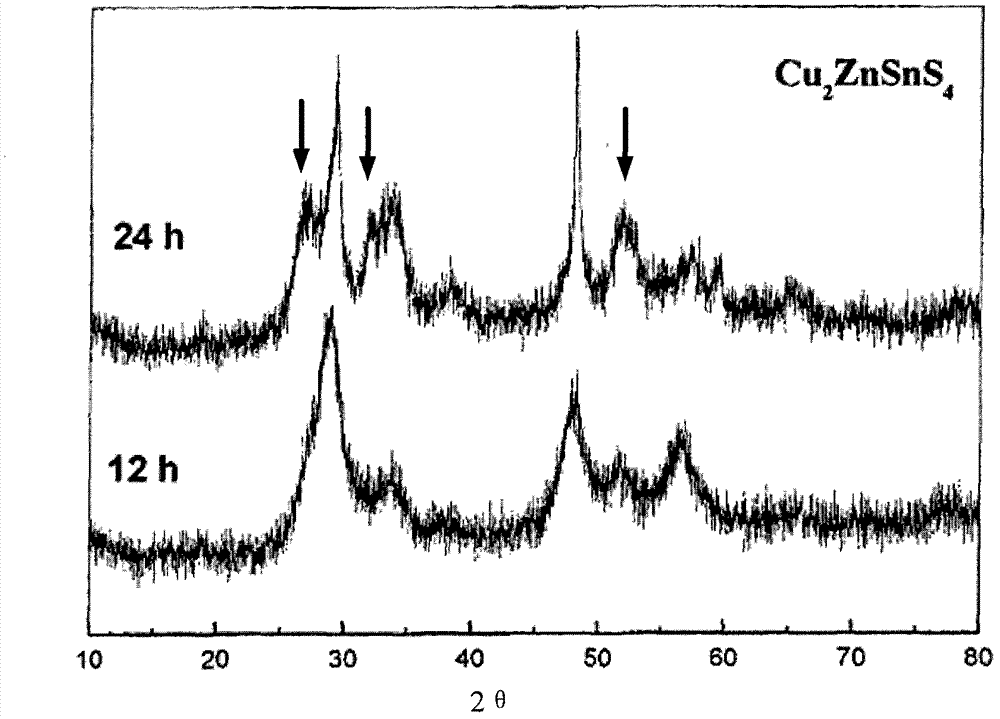

[0088] (2) Seal the reaction kettle, control its reaction temperature to 200°C, and the reaction time is 12 hours; after the reaction, the reaction kettle is naturally cooled to room temperature, the product is filtered or centrifuged, washed several times with absolute ethanol, vacuum Drained to produce Cu 2 ZnSnS 4 Material.

Embodiment 2

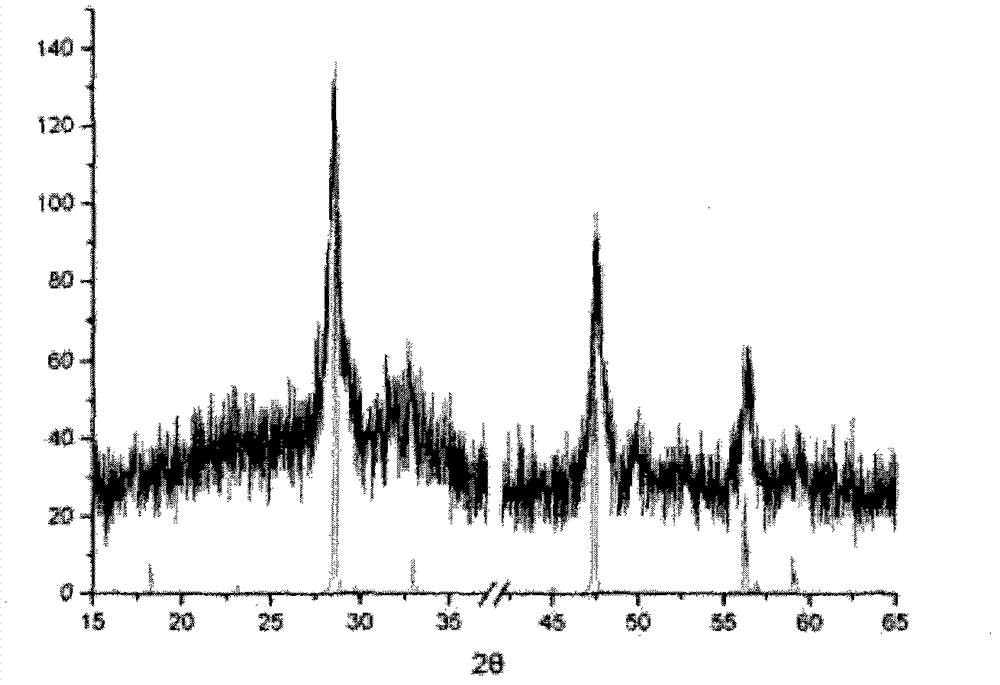

[0090] The steps are the same as in Example 1, except that the reducing agent ascorbic acid in Example 1 is replaced by triethanolamine to obtain Cu 2 ZnSnS 4 nanomaterials.

Embodiment 3

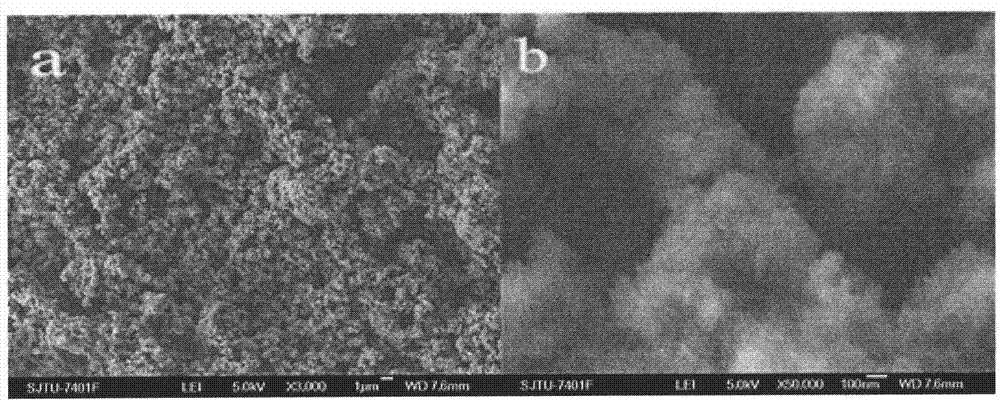

[0092] (1) The amount of substance is expressed in millimoles, and copper acetate, zinc acetate, tin chloride, triethanolamine, thioacetamide and polyvinylpyrrolidone are respectively mixed with the millimole ratio of 2:1:1:2:40:10 Add it into a 50ml polytetrafluoroethylene reaction kettle, then add 40ml of water, stir, and ultrasonically dissolve to form a solution with a concentration of 0.02M (mol / liter), wherein triethanolamine is a reducing agent, and thioacetamide is a sulfur source, polyvinylpyrrolidone is a modifier;

[0093] (2) Seal the reaction kettle, control the reaction temperature to 200°C, and the reaction time is 6 hours. After the reaction, the reaction kettle is naturally cooled to room temperature, the product is centrifuged, washed with water and absolute ethanol several times, and vacuum pumped Dry, get Cu 2 ZnSnS 4 Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com