Formula and manufacturing method of black fungus culture material

A cultivation material, black fungus technology, applied in fertilizer mixture, fertilization device, application and other directions, can solve the problems of air, water source and ecological environment pollution, the proportion of processing is not large, etc., to broaden the channels of cultivation raw materials, fast growth, Thick and thin with reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

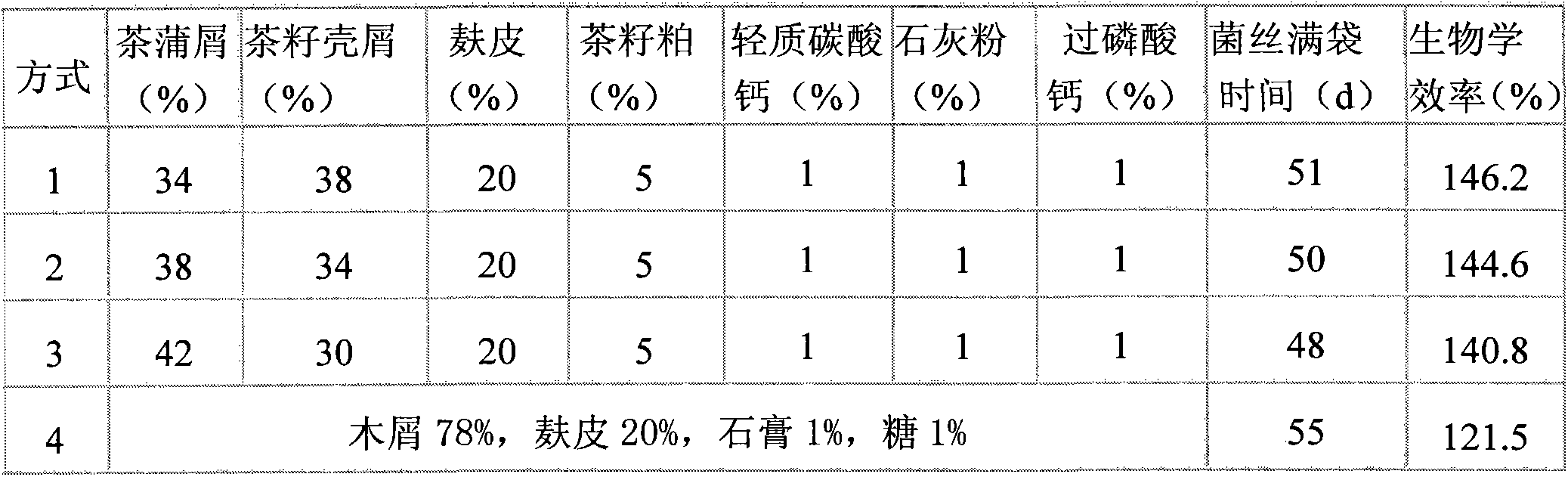

[0022] Method 1: In this example, the black fungus cultivation material includes the following components and mass ratio: 34% of tea cattail, 38% of tea seed husk, 20% of bran, 5% of tea seed meal, and 1% of light calcium carbonate , Lime powder 1%, superphosphate 1%, all are the quality of dry matter, and the sum of the ratios is 100%.

[0023] Production Method:

[0024] ① Pre-wetting: Mix the dry materials of tea cattail crumbs and tea seed husk crumbs evenly, and pre-wet them with lime water (lime powder dissolved in water) for 2 hours to keep the water content of the mixture at 50%-55%;

[0025] ② Mixing material: First mix the bran, tea seed meal, light calcium carbonate, superphosphate dry material, and then mix it into the pre-wet material of tea cattail crumbs and tea seed husk crumbs, then slowly add water while adding While mixing, fully stir evenly to keep the water content of the cultivation material at 63%-65%;

[0026] ③ Bagging: Use a high-pressure polyethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com