Preparation method of high purity fenofibric acid

A fenofibric acid, high-purity technology, applied in the field of preparation of high-purity fenofibric acid, can solve the problems of unpredictable trace impurities in the product, low purity of fenofibric acid, and increased burden on patients, etc., to achieve convenient medicinal use Effects of review, drug cost reduction, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

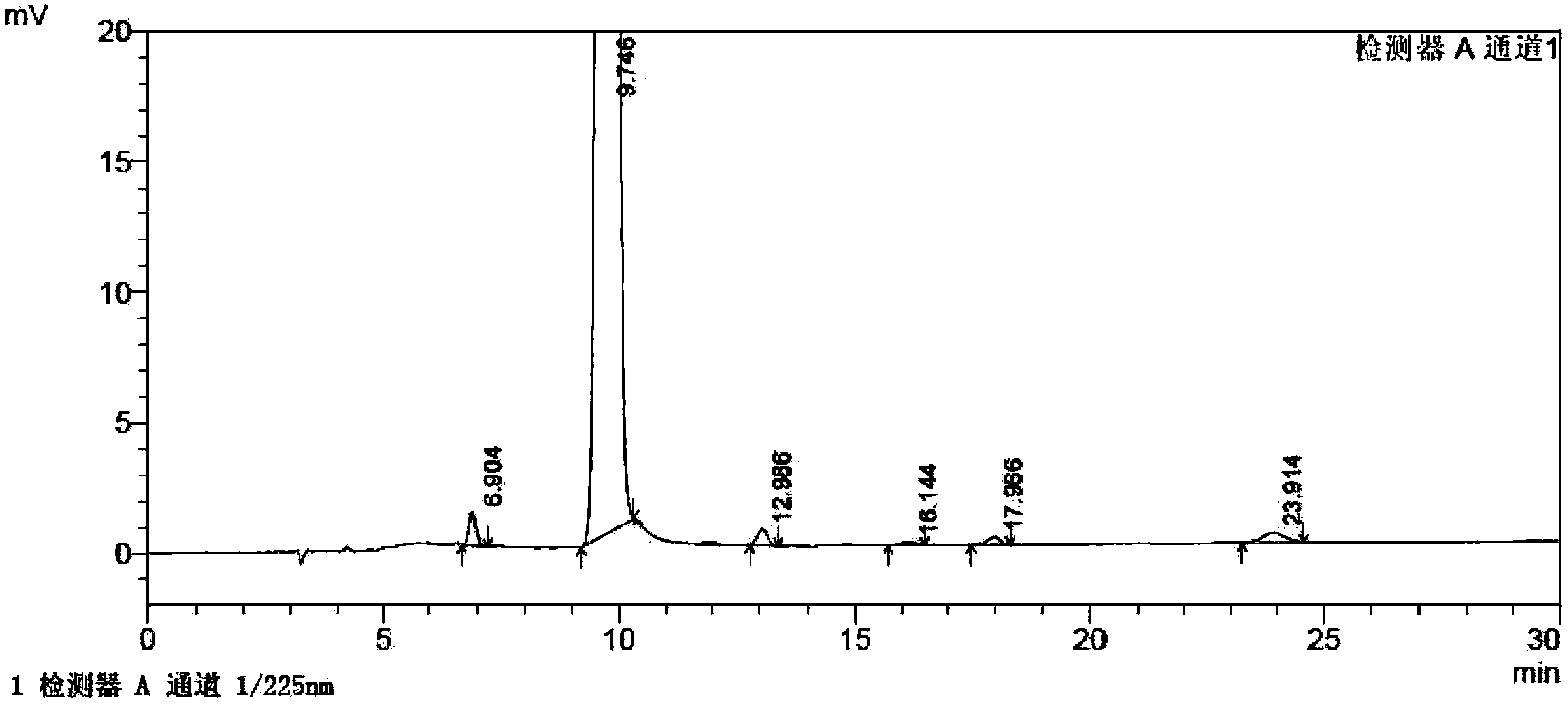

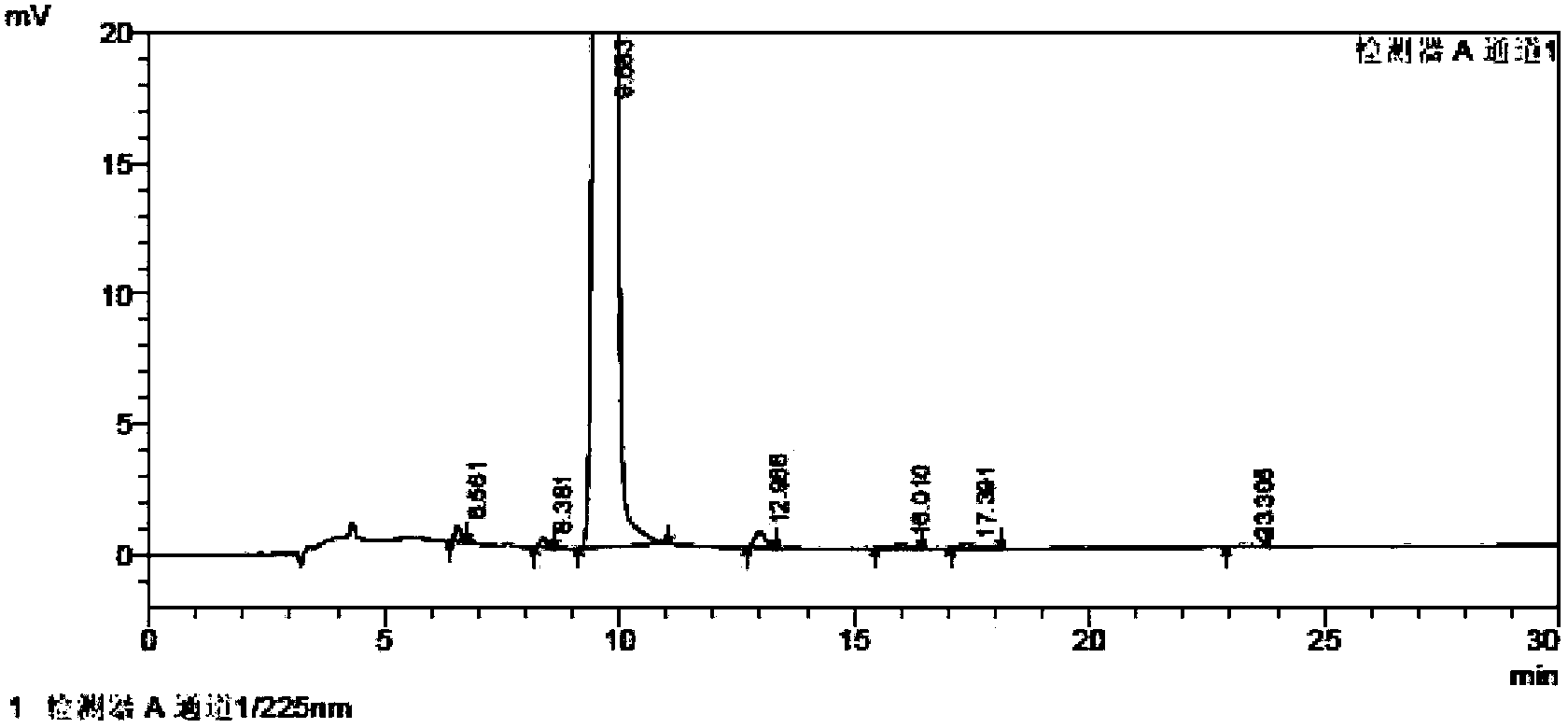

[0044] Example 1 Synthesis of fenofibric acid (tetrabutylammonium bromide catalyzed condensation reaction to synthesize fenofibric acid)

[0045] Weigh 1.00kg of 4-chloro-4'-hydroxybenzophenone, add it to a 20L dry reaction kettle, then add 8.6L of acetone, stir and dissolve, then add 1kg of sodium hydroxide and 138g of tetrabutylammonium bromide . Heat to reflux state, stir for 1 hour, add dropwise 3L of acetone solution of chloroform with a concentration of 1.55kg / 3.0L during stirring, and react at 60°C for 6 hours after the dropwise addition is completed.

Embodiment 2

[0046] The crude purification of embodiment 2 fenofibric acid

[0047]After the reaction in Example 1 was completed, the solvent was concentrated at 40°C until there was no distillate, and then 13L of purified water was added dropwise at room temperature (25°C, the same below). Then add 3.2L of methyl tert-butyl ether to the aqueous solution (water phase), stir for 30 minutes, let stand to separate layers, and keep the water phase. The aqueous phase was continuously extracted with methyl tert-butyl ether as above, and extracted three times in total. Then, add 220g activated carbon (can be purchased from Shanghai Activated Carbon Factory Co., Ltd., specification: Type 767 Needle Class I) to the obtained water phase for decolorization for 0.5 hours, filter the filter bottle, and adjust the pH of the filtrate to 6mol / L hydrochloric acid. 1.5 (room temperature), a large amount of solid precipitated. Filter, wash the filter cake with purified water until the pH of the washed wate...

Embodiment 3

[0048] The refining of embodiment 3 fenofibric acid crude product

[0049] Add 1.3kg of the crude product of fenofibric acid obtained in Example 2 into a 20L three-necked flask, add 13L of toluene, start stirring and heating, and keep warm for 30 minutes when the temperature is raised to 110°C. Then turn off the stirring and filter while it is hot. The filtrate is transferred to a 20L reactor to cool down naturally. During this period, crystals are precipitated. When it is lowered to room temperature, it is placed in a refrigerator at 10°C for 12 hours, then suction filtered, and the filter cake is washed twice with toluene. (Use 500ml of toluene each time), drain.

[0050] Collect the filter cake, dry it (about 1250g) and put it into a 20L three-necked bottle, then add 9.2L of pure water, adjust the pH to 9.5 with sodium hydroxide, and add 6mol / L hydrochloric acid dropwise after the fenofibric acid is completely dissolved When the pH reached 1.5, a white solid was precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com