Biomass aldehyde-free adhesive for plywood

A technology of plywood and biomass, applied in the direction of starch-derived adhesives, unsaturated alcohol copolymer adhesives, adhesive types, etc., can solve the problems of unstable storage, environmental temperature sensitivity, and large viscosity changes. Achieve the effect of simple process, easy source and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

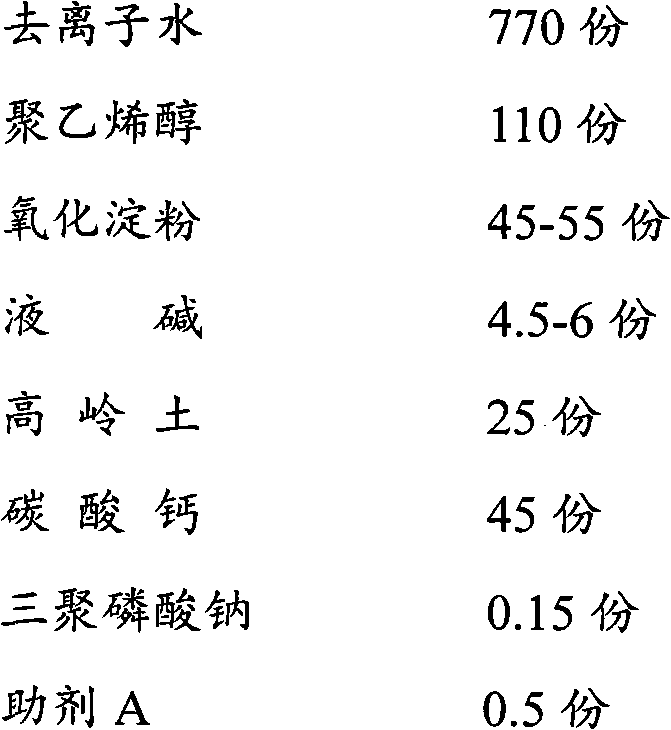

[0021] Embodiment one, comprising the proportioning composition of the following components by weight:

[0022]

[0023] The weight of one portion can be set as required, which can be one kilogram, two kilograms, one gram, two grams, three grams, etc., and can be configured according to the amount required.

[0024] The manufacturing process of this kind of biomass formaldehyde-free plywood adhesive comprises the following process steps:

[0025] 1. Add 670 parts of deionized water to the reactor; then add polyvinyl alcohol; heat up to 90 degrees to fully dissolve the polyvinyl alcohol; wait until the polyvinyl alcohol is fully dissolved, then lower the temperature;

[0026] 2. When the temperature is lowered to 60 degrees, put in a dispersion composed of 50 parts of deionized water and oxidized starch; add liquid caustic soda to adjust the pH value to 7.5-8, then raise the temperature to 90 degrees, keep it warm for 30-40 minutes, and carry out gelatinization reaction ; ...

Embodiment 2

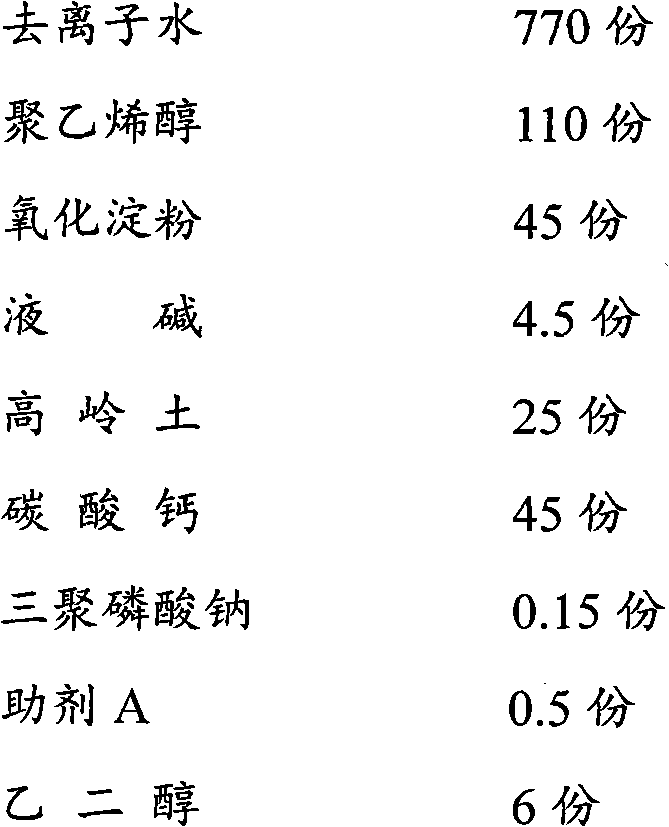

[0029] Embodiment two, comprising the proportioning composition of following component parts by weight:

[0030] The weight of one portion can be set as required, which can be one kilogram, two kilograms, one gram, two grams, three grams, etc., and can be configured according to the amount required.

[0031]

[0032] Also includes Enhancer 100 parts. It can improve the bonding strength of the adhesive.

[0033] It also includes 1.5 parts of antiseptic and antifungal agent. It can effectively prevent the adhesive from mildew and corruption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com