Blast-furnace smelting method for vanadium-titanium magnetite

A vanadium-titanium magnetite, blast furnace smelting technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of high iron content and high iron loss, and achieve the effects of reducing slag viscosity, iron content, and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

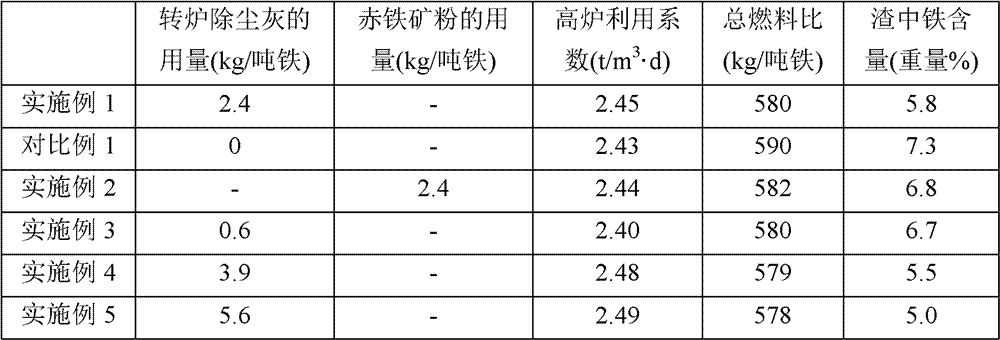

Examples

preparation example Construction

[0019] The preparation method of the vanadium-titanium sintered ore can be carried out according to the conventional preparation method in the art, for example, the preparation method of the vanadium-titanium sintered ore can include: combining vanadium-titanium iron concentrate and common iron concentrate with fuel (charcoal, coke powder) mixed with flux (quicklime and / or limestone) and sintered. Wherein, the dosage of vanadium-titanium iron concentrate and ordinary iron concentrate can be the conventional dosage of vanadium-titanium-iron concentrate in the preparation of sintered ore in this field. 50-55% by weight of the total weight, and the amount of ordinary iron concentrate is 25-30% by weight of the total weight of raw materials used to form vanadium-titanium sintered ore. The commonly used sintering method is sintering on a belt sintering machine, for example, adding mixed iron concentrate (that is, a mixture of vanadium-titanium iron concentrate and ordinary iron con...

preparation example 1

[0038] Preparation Example 1: Preparation of Vanadium-Titanium Sintered Ore

[0039] The vanadium-titanium iron ore concentrate of 52 parts by weight, the common iron ore concentrate of 28 parts by weight, the coke powder of 52 parts by weight and the unslaked lime of 15 parts by weight carry out cloth on the magnetic roller distributor and add on the trolley, then in 1350 Sintering in a sintering machine at ℃ for 30 minutes, the sintering machine speed is 1.71m / min, the vertical sintering speed is 21.60mm / min, and the drum strength is 72.51%, then the vanadium-titanium sintered ore is obtained. It is 22.85mm.

[0040] Described drum strength is the ISO drum strength defined according to GB13242, refers to get 7.5 kilograms of sintered ore of 40-10mm in ISO drum machine (SQZG--4 type; Hebi City Metallurgical Machinery Equipment Co., Ltd.) after rotating 200 revolutions, The percentage of >6.3mm particle size sinter in the weight of the whole sinter is an important index to me...

preparation example 2

[0041] Preparation Example 2: Preparation of Vanadium-Titanium Pellets

[0042] Put 92 parts by weight of vanadium-titanium iron ore concentrate, 8 parts by weight of common iron ore concentrate and 2.2 parts by weight of bentonite into a large electric mixer (HXDH-15L; Shangyu Hongxing Machinery Manufacturing Co., Ltd.) Mix evenly, put into large-scale ball mill (ASM type horizontal ball mill; Wuxi City Haibo Drying Machinery Equipment Factory) internal moistening after mixing, utilize disc pelletizer (Tangshan Tangye Reducer Manufacturing Co., Ltd.) to pelletize, Air-dried on a chain grate machine (Jiaozuo Zhengyuan Machinery Manufacturing Co., Ltd.), with a wind speed of 1.5m / s, an initial drying temperature of 50°C, a preheating temperature of 600°C, and roasting in a rotary kiln at a roasting temperature of 1200°C , Roasted for 30 minutes to obtain vanadium-titanium pellets. The compressive strength of the vanadium-titanium pellets is 3310N / piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com