Plasma cladding gradient wearing layer and its preparation technology

A technology of plasma cladding and preparation process, applied in the direction of metal material coating process, coating, etc., can solve problems such as peeling, stress concentration, cracks, etc., and achieve the effect of preventing layer peeling, low wear amount, and improved impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

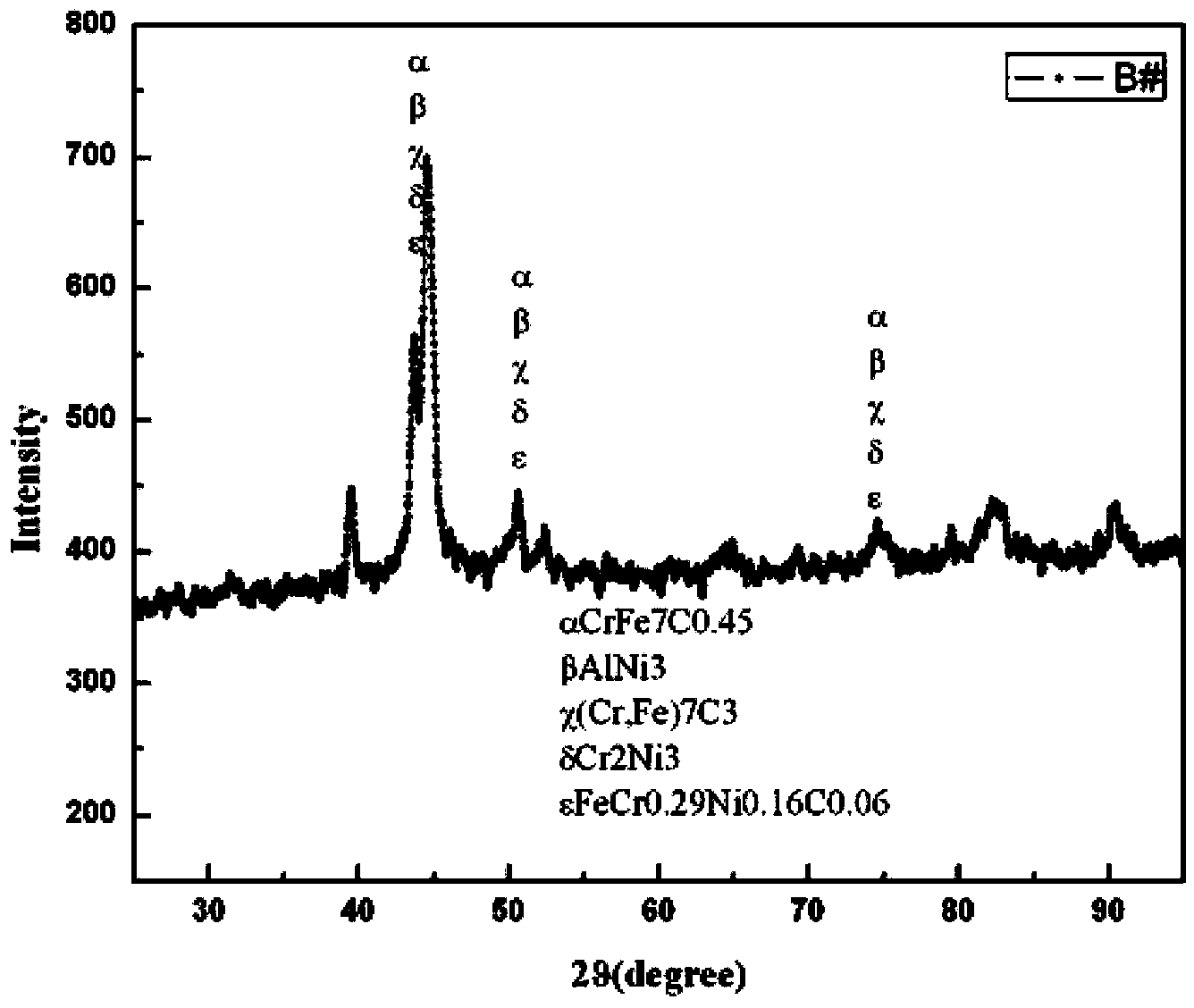

[0030] The composition (weight %) of the cladding layer in the plasma cladding gradient wear-resistant layer is as follows:

[0031] Si: 2%, Mn: 2%, Al: 1%, Mo: 0.5%, Ni: 4%, Cr 3 C 2 : 30%, the balance is Fe.

[0032] The composition (weight %) of the outer cladding layer of the plasma cladding gradient wear-resistant layer is as follows:

[0033] Si: 2%, Mn: 2%, Al: 1%, Mo: 0.5%, Ni: 4%, Cr 3 C 2 : 40%, the balance is Fe.

[0034] The gradient wear-resistant layer is prepared as follows:

[0035] First, in order to ensure the effect of plasma cladding, trichlorethylene was used to remove impurities and oil stains on the surface of the substrate (#45 steel), and the substrate was preheated at 140°C. The component powders are screened by sieving method and microscopic observation method. The particle size distribution is between 80 and 100 mesh. Put it into a drying oven for drying, the temperature is controlled at 150°C, and the powder is turned during the drying proce...

Embodiment 2

[0037] The composition (weight %) of the cladding layer in the plasma cladding gradient wear-resistant layer is as follows:

[0038] Si: 2%, Mn: 2%, Al: 1%, Mo: 0.5%, Ni: 4%, Cr3 C 2 : 30%, the balance is Fe.

[0039] The composition (weight %) of the outer cladding layer of the plasma cladding gradient wear-resistant layer is as follows:

[0040] Si: 2%, Mn: 2%, Al: 1%, Mo: 0.5%, Ni: 4%, Cr 3 C 2 : 50%, the balance is Fe.

[0041] The process parameters for preparing the inner cladding layer using PLC plasma spray welding equipment are as follows:

[0042] Plasma gas: argon, working current: 120A, working voltage: 17.5V, protective gas flow: 1.2m 3 / h, power gas flow: 0.8m 3 / h, distance from nozzle to surface: 10mm, scanning speed: 190mm / min.

[0043] The process parameters for preparing the outer cladding layer using PLC plasma spray welding equipment are as follows:

[0044] Plasma gas: argon, working current: 127A, working voltage: 16.9V, protective gas flow: 1.2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com