Two-stage expansion power generation device and method for recovering liquefied natural gas cold energy

A technology of liquefied natural gas and two-stage expansion, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of low demand for direct cooling, complex process flow, and low efficiency, and achieve less equipment, simple process, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

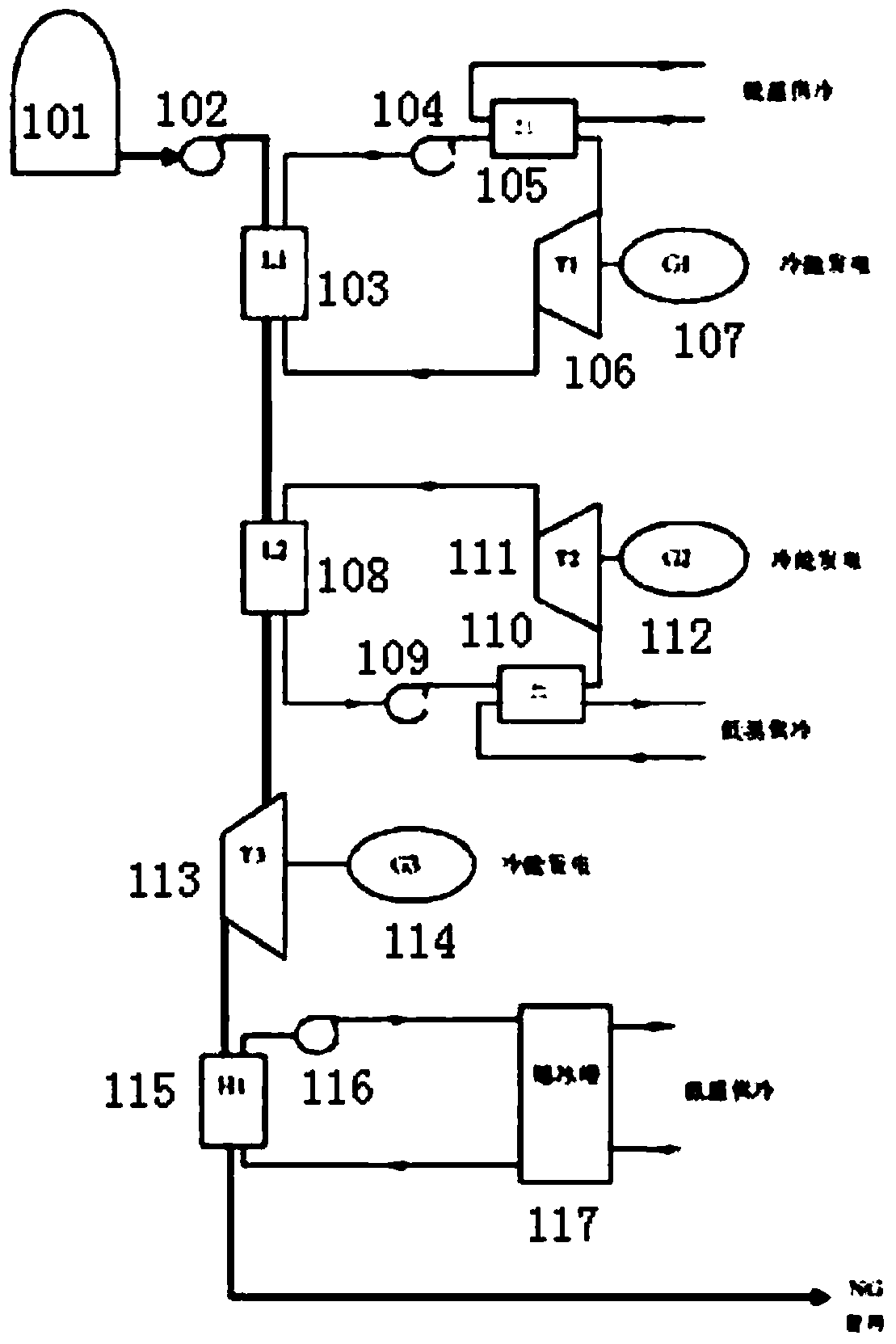

[0028] like Figure 5 As shown, the two-stage expansion power generation device for recovering the cold energy of liquefied natural gas of the present invention includes an LNG pump 11, a plate-fin multi-stream low-temperature heat exchanger 12, first to fourth heat exchangers 13-16, a first stage turboexpander 17 , first generator 18 , second stage turboexpander 19 , second generator 20 , first working medium pump 21 and second working medium pump 22 .

[0029] One end of the LNG pump 11 is connected to the LNG supply source (not shown in the figure), and the other end of the LNG pump 11 is connected to the inlet of the first flow channel (a) of the plate-fin multi-stream cryogenic heat exchanger 12, the plate-fin type The outlet of the first flow channel (a) of the multi-stream cryogenic heat exchanger 12 is connected to the inlet of the first heat exchanger 13, and the outlet of the first heat exchanger 13 is connected to the export pipeline NG.

[0030] The output work of...

Embodiment 2

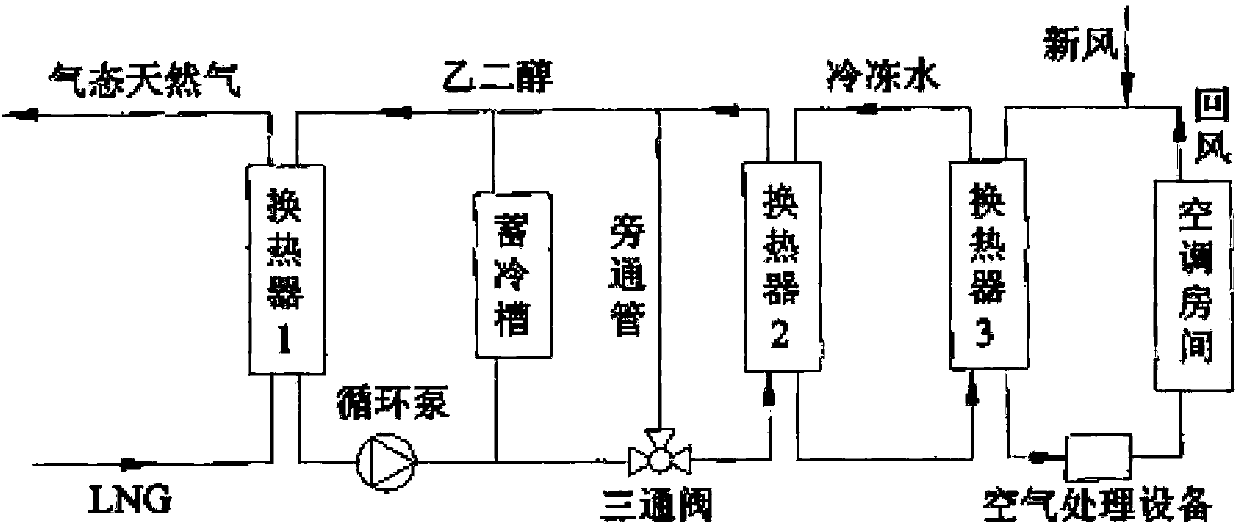

[0038] like Image 6 As shown, according to whether there is suitable industrial waste heat available on site, the industrial waste heat can be used to improve power generation efficiency under possible conditions. The structure of this embodiment is exactly the same as that of embodiment 1, the only difference is that the The fourth heat exchanger 16 can exchange heat with industrial waste heat. Wherein, the working fluid is heated to 40°C-90°C by using industrial waste heat, preferably 50°C-80°C.

Embodiment 3

[0040] like Figure 7 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: a fifth heat exchanger 23 and a natural gas expander 24 are also included; the outlet of the first heat exchanger 13 in Embodiment 1 is connected The inlet of the fifth heat exchanger 23 and the outlet of the fifth heat exchanger 23 are connected to the inlet of the natural gas expander 24, and the outlet of the natural gas expander 24 is connected to the export pipeline NG.

[0041] After the LNG passes through the LNG pump 11 to increase the pressure to 8MPa-15MPa, it enters the first channel of the plate-fin multi-stream low-temperature heat exchanger 12 to be vaporized and heated up. After heat exchange, the LNG is first exchanged with the refrigerant in the first heat exchanger 13. The heat is then exchanged with the external environment through the fifth heat exchanger 23, and sent to the natural gas turbo expander 24 after the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com