Method for evaluating damage severity degree of external anticorrosive coating of pipeline

A technology of severity and evaluation method, which is applied in the field of evaluation of the damage severity of the outer anti-corrosion layer of the pipeline, and can solve the problems of large differences in the damage of the anti-corrosion layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

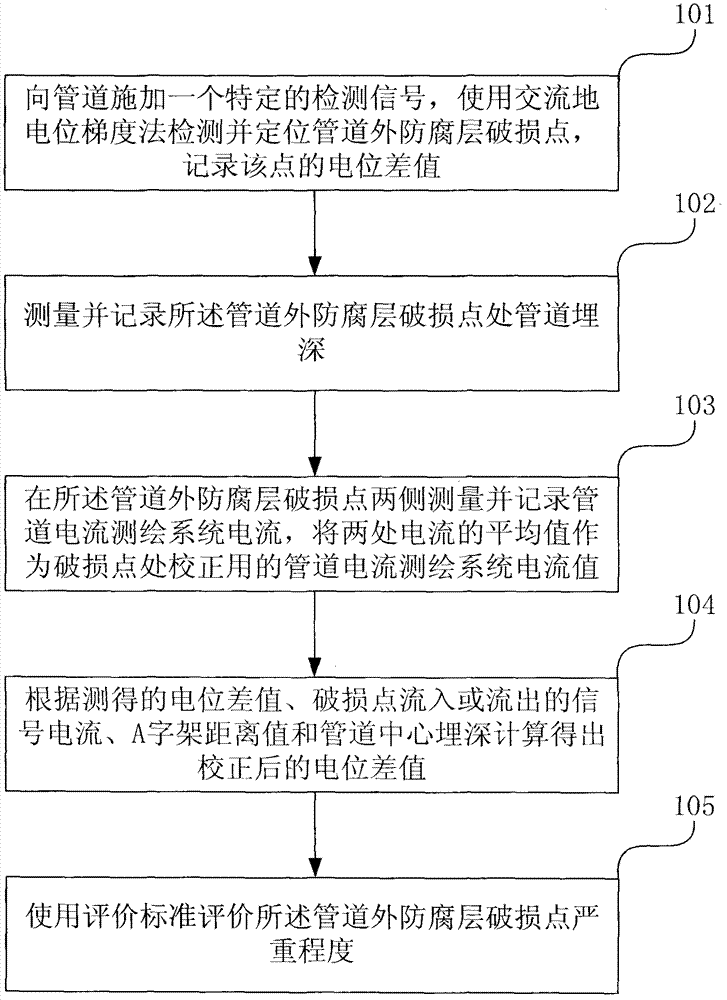

[0021] figure 1 It is the flow chart of the evaluation method embodiment of the damage severity degree of the outer anti-corrosion layer of the pipeline of the present invention, as figure 1 shown, including the following steps:

[0022] Step 101, apply a specific detection signal to the pipeline, use the AC ground potential gradient method to detect and locate the damaged point of the outer anti-corrosion layer of the pipeline, and record the potential difference at this point. After a specific detection signal is applied to the pipeline, the signal propagates along the pipeline and gradually attenuates. When the anti-corrosion layer outside the pipeline is damaged and the metal of the pipeline body is directly connected with the soil medium around the pipeline, the signal current will flow from the pipeline regardless of the frequency of the detection signal. The damaged part flows into or out of the pipeline, with the inflow or outflow point as the center, forming a superi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com