Method for preparing hypereutectic aluminum-silicon alloy semi-solid slurry or billet

A technology of semi-solid slurry and aluminum-silicon alloy, which is applied in the field of preparation of hypereutectic aluminum-silicon alloy semi-solid slurry or billet, which can solve problems affecting plasticity and wear resistance, reducing alloy mechanical properties, local stress concentration, etc. , to achieve the effect of excellent mechanical properties, good surface quality and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

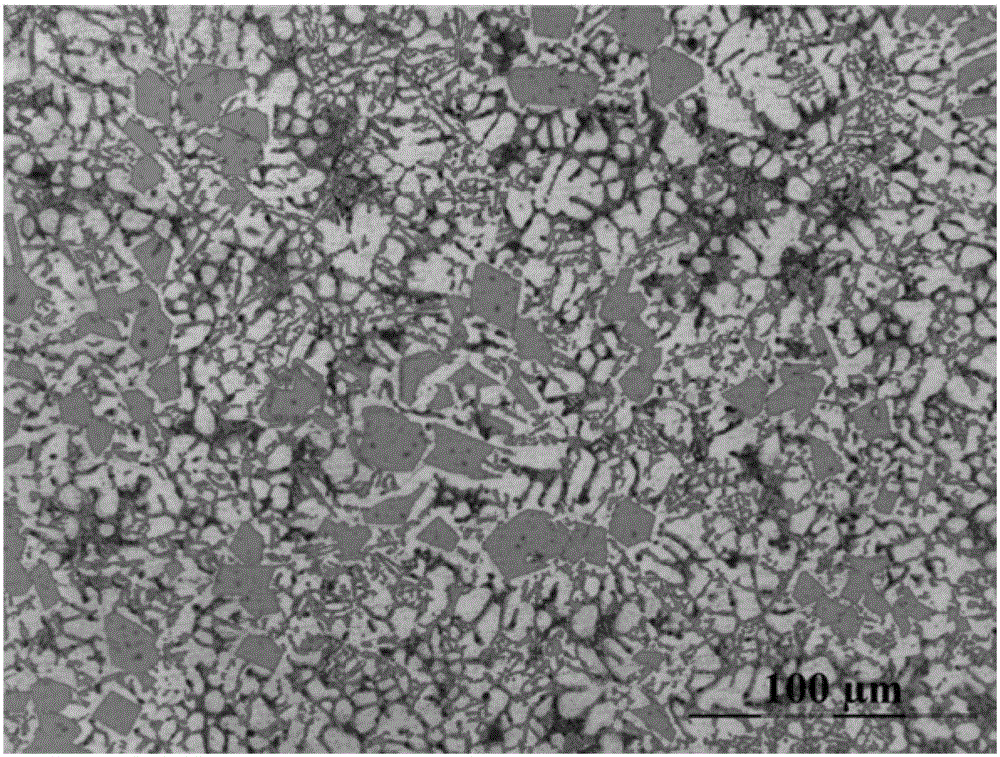

Embodiment 1

[0028] This embodiment relates to a method for preparing a hypereutectic aluminum-silicon alloy semi-solid slurry, which includes the following steps:

[0029] Step 1. Pre-process an aluminum-silicon alloy of model AlSi12Cu (wherein, the weight percentage of Si is 12.5-13.5%, and the liquidus temperature of the aluminum-silicon alloy is 600-610℃) at a temperature of 150-250℃. Heat, add it to the crucible resistance furnace and heat it to melt. After the aluminum-silicon alloy is melted, stir at a temperature of 670~680℃, let it stand for 10-15 minutes for the first time, cool to 650~660℃, refining for 10-15 minutes, and stir. Take off the slag and let it stand for the second time for 10-20 minutes while adjusting the temperature of the aluminum-silicon alloy melt so that the temperature is 30-60℃ higher than the liquidus temperature of the alloy;

[0030] Step 2: Apply the cast aluminum alloy paint of Weifang Huashi Casting Materials Co., Ltd. on the inner wall of the mechanical dr...

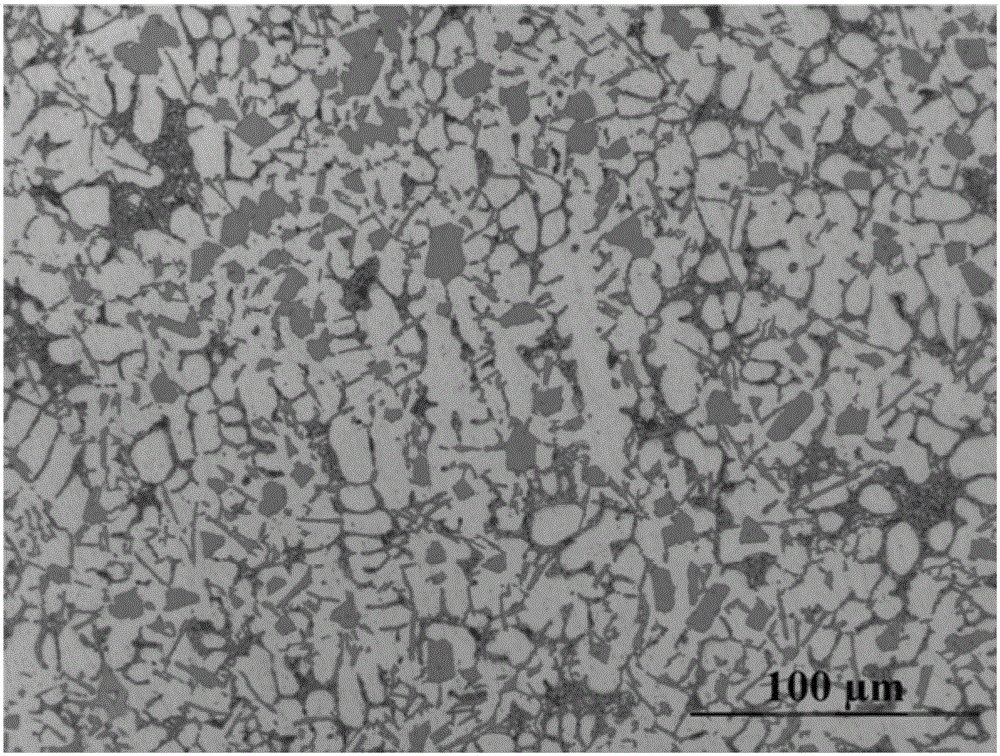

Embodiment 2

[0033] This embodiment relates to a method for preparing a hypereutectic aluminum-silicon alloy semi-solid slurry, which includes the following steps:

[0034] Step 1. Pre-process the aluminum-silicon alloy model YL117 (wherein, the weight percentage of Si is 16-18%, and the liquidus temperature of the aluminum-silicon alloy is 690-700℃) at a temperature of 150-250℃. Heat, add it to a crucible resistance furnace and heat it to melt. After the aluminum-silicon alloy is melted, stir at a temperature of 680~750℃, let it stand for 10-15 minutes for the first time, cool to 680~720℃, refining for 10-15 minutes, stirring Take off the slag and let it stand for the second time for 10-20 minutes while adjusting the temperature of the aluminum-silicon alloy melt so that the temperature is 30-60℃ higher than the liquidus temperature of the alloy;

[0035] Step 2: Preheat the mechanical drum coated with the casting aluminum alloy coating of Weifang Huashi Casting Materials Co., Ltd. to 300°C. T...

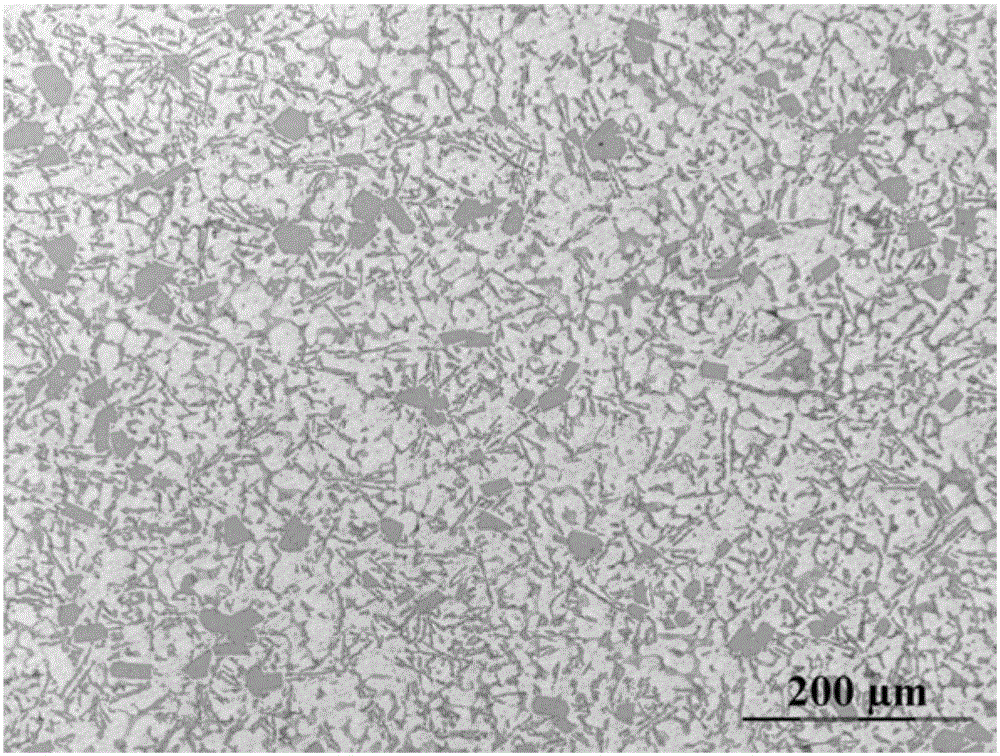

Embodiment 3

[0038] This embodiment relates to a method for preparing a hypereutectic aluminum-silicon alloy semi-solid blank, which includes the following steps:

[0039] Step 1. Pre-process the aluminum-silicon alloy model YL117 (wherein, the weight percentage of Si is 16-18%, and the liquidus temperature of the aluminum-silicon alloy is 690-700℃) at a temperature of 150-250℃. Heat, add it to a crucible resistance furnace and heat it to melt. After the aluminum-silicon alloy is melted, stir at a temperature of 680~750℃, let it stand for 10-15 minutes for the first time, cool to 680~720℃, refining for 10-15 minutes, stirring Take off the slag and let it stand for the second time for 10-20 minutes while adjusting the temperature of the aluminum-silicon alloy melt so that the temperature is 30-60℃ higher than the liquidus temperature of the alloy;

[0040] Step 2: Apply the cast aluminum alloy paint of the aluminum alloy casting Weifang Huashi Casting Materials Co., Ltd. on the inner wall of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com