Production device for preparing 2, 6-dichlorobenzonitrile

A production device, the technology of dichlorobenzonitrile, applied in the direction of nitrogen oxide-organic compound reaction preparation, organic chemistry, etc., can solve the problems of not being able to meet the market demand, difficult production control, low output, etc., to achieve reasonable design of production equipment, The effect of reducing the generation of solid waste and reducing the consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

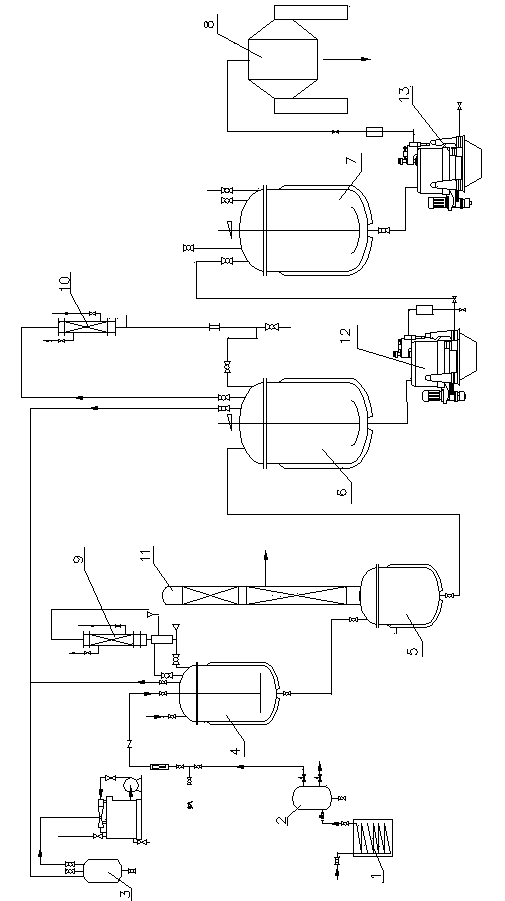

[0012] The present invention is provided with evaporator 1, buffer tank 2, hydrogen chloride recovery tank 3, chlorination kettle 4, first rectification kettle 5, hydrolysis nitrilation kettle 6, second rectification kettle 7, drying machine 8, the first condenser device 9, second condenser 10 and rectification column 11.

[0013] A light source is arranged in the chlorination kettle 4, and the evaporator 1 is connected to a feed port of the chlorination kettle 4 through a buffer tank 2, and a 2,6-dichlorotoluene feed inlet and phosphorus pentachloride are also respectively arranged on the chlorination kettle 4. The feed port and the jacket of the chlorination kettle 4 are connected to the first condenser 9 to control the temperature of the material in the chlorination kettle 4 .

[0014] The inlet end of the hydrogen chloride recovery tank 3 is connected with the gas outlet that is arranged on the top of the chlorination kettle 4 .

[0015] The discharge port at the lower to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com