Method and device for producing o-chloroaniline without solvent

An o-chloroaniline, solvent-free technology, applied in the field of chemical production, can solve the problems of difficulty in judging the reaction end point, increased product cost, and high operational risk, and achieves low labor intensity for workers, good product quality, and high reaction selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

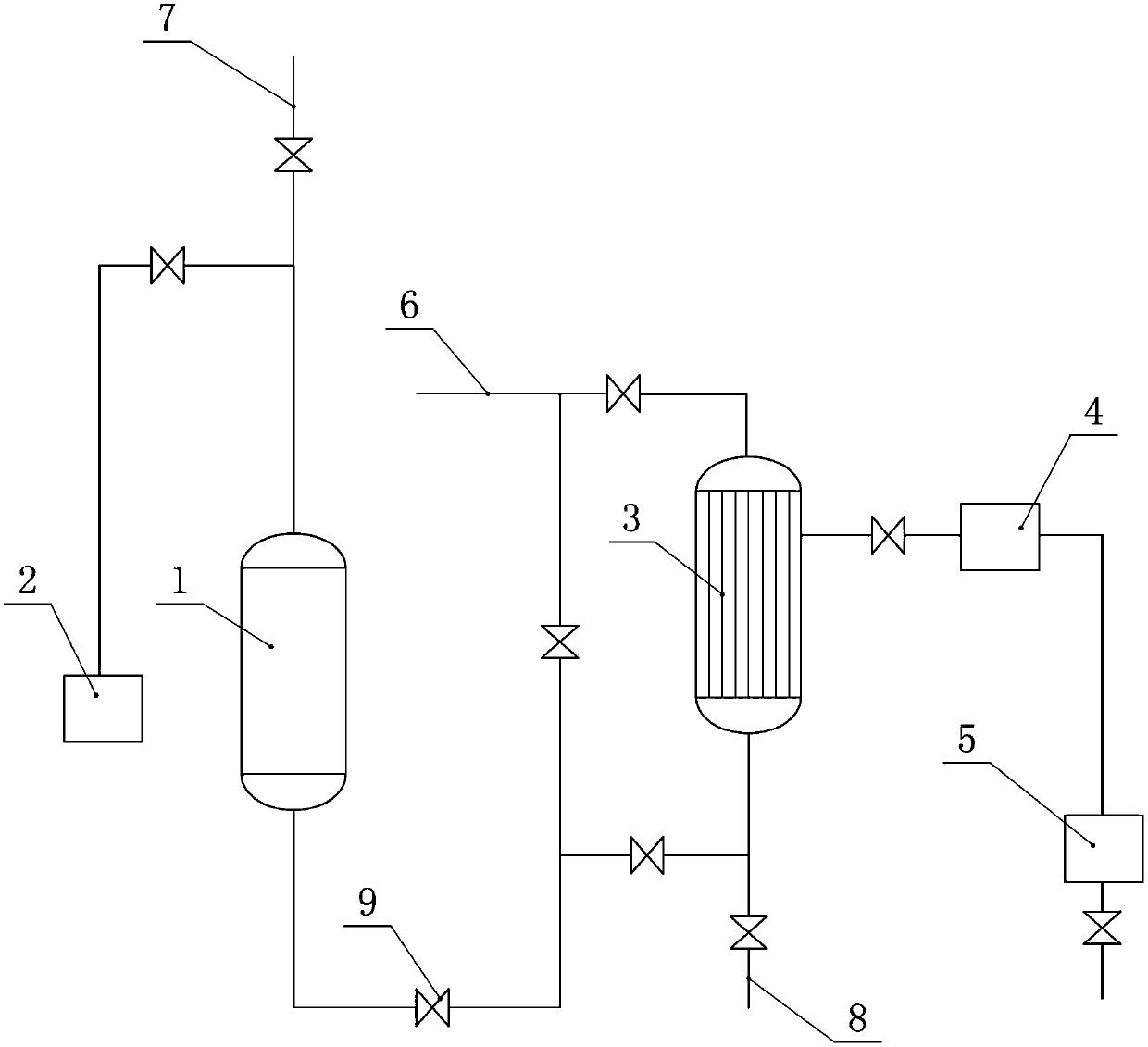

[0027] The present invention includes: a reaction kettle 1 (hydrogenation kettle) connected to a hydrogen inlet pipe 6, the reaction kettle 1 and the hydrogen inlet pipe 6 are all connected to the catalyst filter 3, the catalyst recovery tank 2 is connected to the reaction kettle 1, and the catalyst filter 3 is connected to the test mirror 4 is connected, the test mirror 4 is connected with the hydrogenation liquid tank 5, and the sampling pipeline is on the 1 and 2 communication pipelines. The upper part of the reaction kettle 1 is provided with a sampling port, and the sampling tube is inserted into the bottom of the reaction kettle 1 .

[0028] The feeding sequence is as follows: put o-chloronitrobenzene, additives 1 and 2 and new catalysts into the reactor 1, feed hydrogen gas under a certain pressure and temperature, continue the reaction in the hydrogenation kettle, and pass through the catalyst filter 3 after the hydrogenation is qualified. Filter the catalyst, and take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com