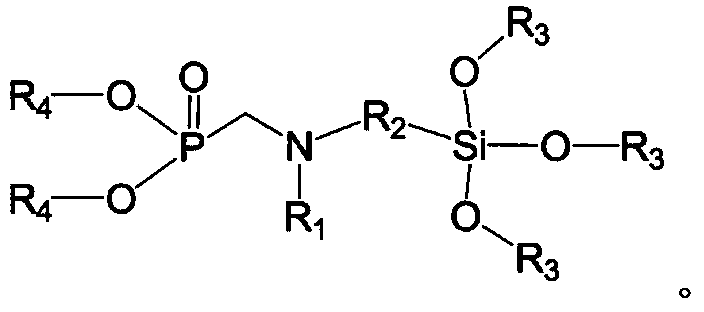

Phosphor-nitrogen containing silane A, phosphite ester halogen-free flame retardant containing nitrogen phosphor silicon and preparation method of phosphite ester halogen-free flame retardant

A nitrogen silane and flame retardant technology, which is applied in the field of phosphite halogen-free flame retardants and their preparation, can solve the problems of low flame retardant efficiency, achieve small color influence, high flame retardant effect, and broad industrial application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

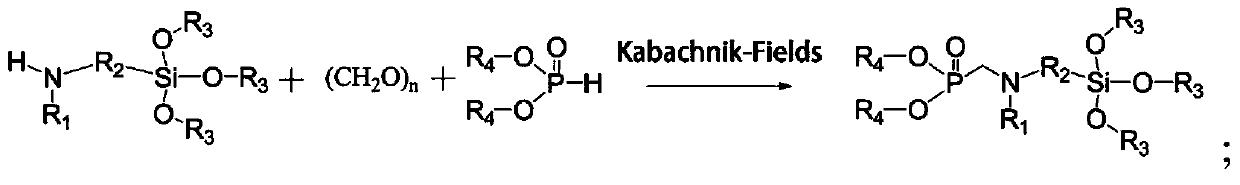

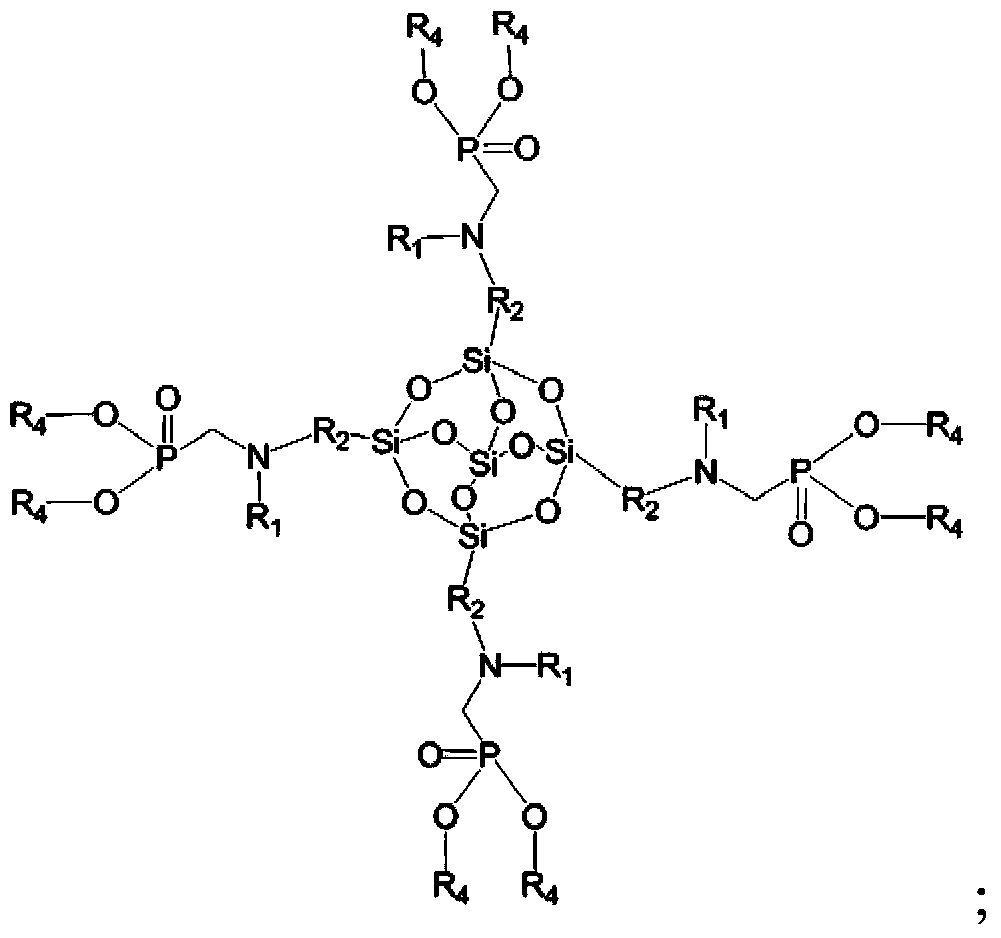

Method used

Image

Examples

Embodiment 1

[0032] 1) In a 500ml three-necked flask equipped with mechanical stirring and a constant pressure dropping funnel, add 66.3g (0.3mol) 3-aminopropyltriethoxysilane and 200ml tetrahydrofuran, and stir at 30-40°C for 10 minutes, Add 9g (0.3mol) of paraformaldehyde, warm up to 65-70°C after 1 hour of heat preservation reaction, then add 66.0g (0.6mol) of dimethyl phosphite dropwise within 2 hours, and stop the reaction after 12 hours of heat preservation reaction. Remove the solvent, dissolve the crude product in 200ml chloroform, wash three times with 0.1mol / L sodium hydroxide solution, wash three times with deionized water, dry over anhydrous magnesium sulfate and remove chloroform to obtain a light yellow transparent liquid, which is reactant a.

[0033] Product A structural characterization:

[0034] FTIR (KBr, cm -1 ):2984-2905(ν C-H ),1269(ν P=O ),1196(ν C-N ),1103-1080(ν Si-O ), 1046-965 (ν P-O ). 1 H-NMR (400MHz, CDCl 3 -d,ppm):3.83(dd,6H),3.66(d,12H),2.84(d,4H),2...

Embodiment 2

[0038] 1) In a 500ml three-necked flask equipped with mechanical stirring and constant pressure dropping funnel, add 70.6g (0.3mol) N-methyl-3-aminopropyltrimethoxysilane and 200ml tetrahydrofuran, and stir at 30-40°C After 10 minutes, add 9g (0.3mol) paraformaldehyde, warm up to 65-70°C after 1 hour of heat preservation reaction, then add 33.0g (0.3mol) of dimethyl phosphite dropwise within 2 hours, and heat preservation reaction for 12 hours Stop responding. Remove the solvent, dissolve the crude product in 200ml chloroform, wash three times with 0.1mol / L sodium hydroxide solution, wash three times with deionized water, dry over anhydrous magnesium sulfate and remove chloroform to obtain a light yellow transparent liquid, which is Reactant A.

[0039] Product A structural characterization:

[0040] FTIR (KBr, cm -1 ):2984-2905(ν C-H ),1269(ν P=O ),1196(ν C-N ),1103-1080(ν Si-O ), 1046-965 (ν P-O ). 1 H-NMR (400MHz, CDCl 3 -d,ppm):3.83(dd,6H),3.66(d,6H),2.84(d,2H),2...

Embodiment 3

[0044] 1) In a 500ml three-necked flask equipped with mechanical stirring and a constant pressure dropping funnel, add 76.6g (0.3mol) N-phenyl-3-aminopropyltrimethoxysilane and 200ml tetrahydrofuran, and stir at 30-40°C After 10 minutes, add 9g (0.3mol) paraformaldehyde, warm up to 65-70°C after 1 hour of heat preservation reaction, then add 33.0g (0.3mol) of dimethyl phosphite dropwise within 2 hours, and heat preservation reaction for 12 hours Stop responding. Remove the solvent, dissolve the crude product in 200ml chloroform, wash three times with 0.1mol / L sodium hydroxide solution, wash three times with deionized water, dry over anhydrous magnesium sulfate and remove chloroform to obtain a light yellow transparent liquid, which is reactant a.

[0045] Product A structural characterization:

[0046] FTIR (KBr, cm -1 ):2984-2905(ν C-H ),1600-1490(δ aromatic C=C ),1269(ν P=O ),1196(ν C-N ),1103-1080(ν Si-O ), 1046-965 (ν P-O ). 1 H-NMR (400MHz, CDCl 3 -d,ppm):6.7-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com