Secondary separation device for hybrid material of corn kernels

A technology of mixed materials and secondary separation, applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of poor flowability of corn kernels and small impurities, difficult to return to the main cleaning screen, and the length of the drum shaft and main frame. , to achieve the effect of simple structure, reduced length, safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

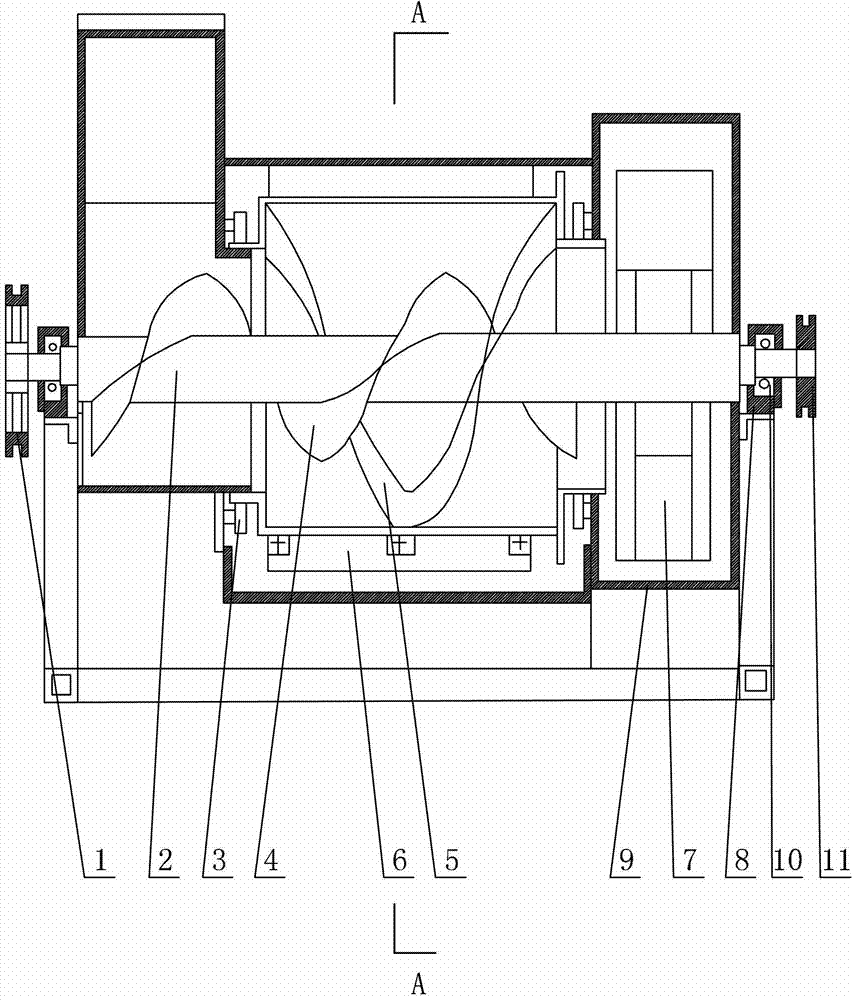

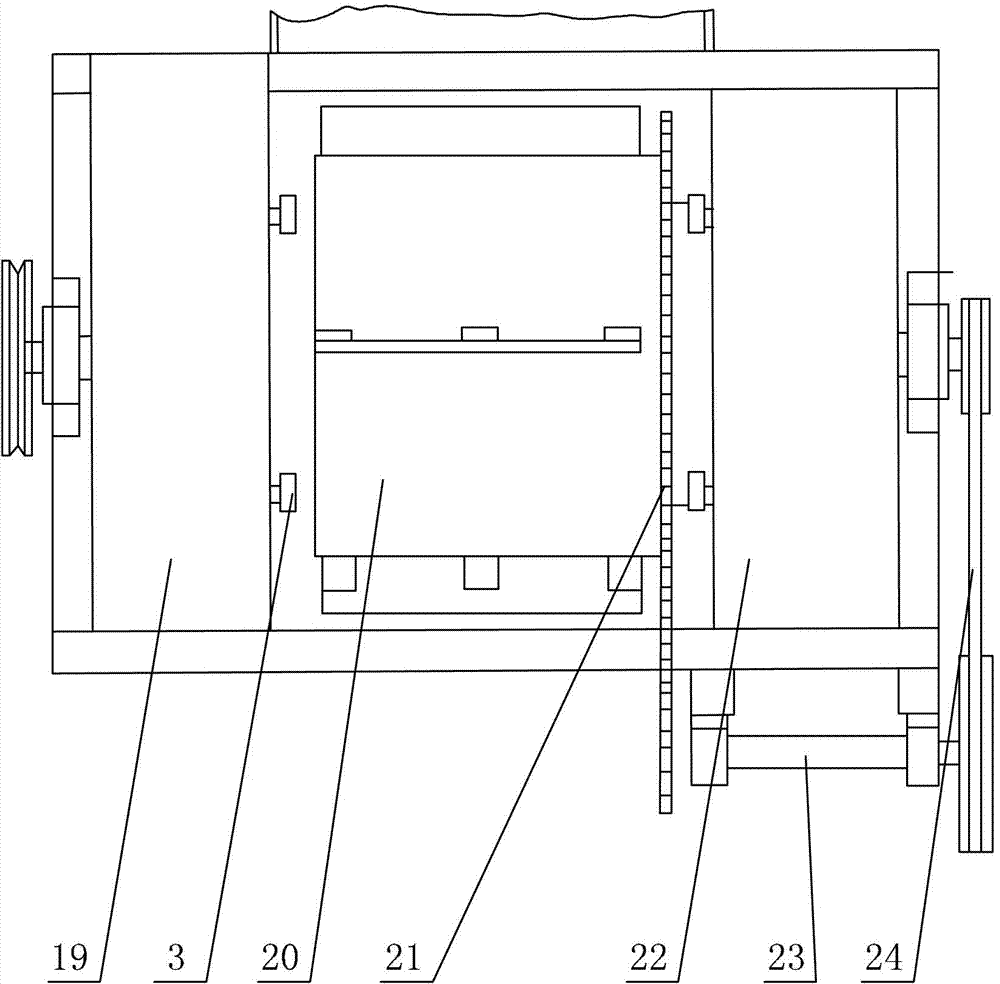

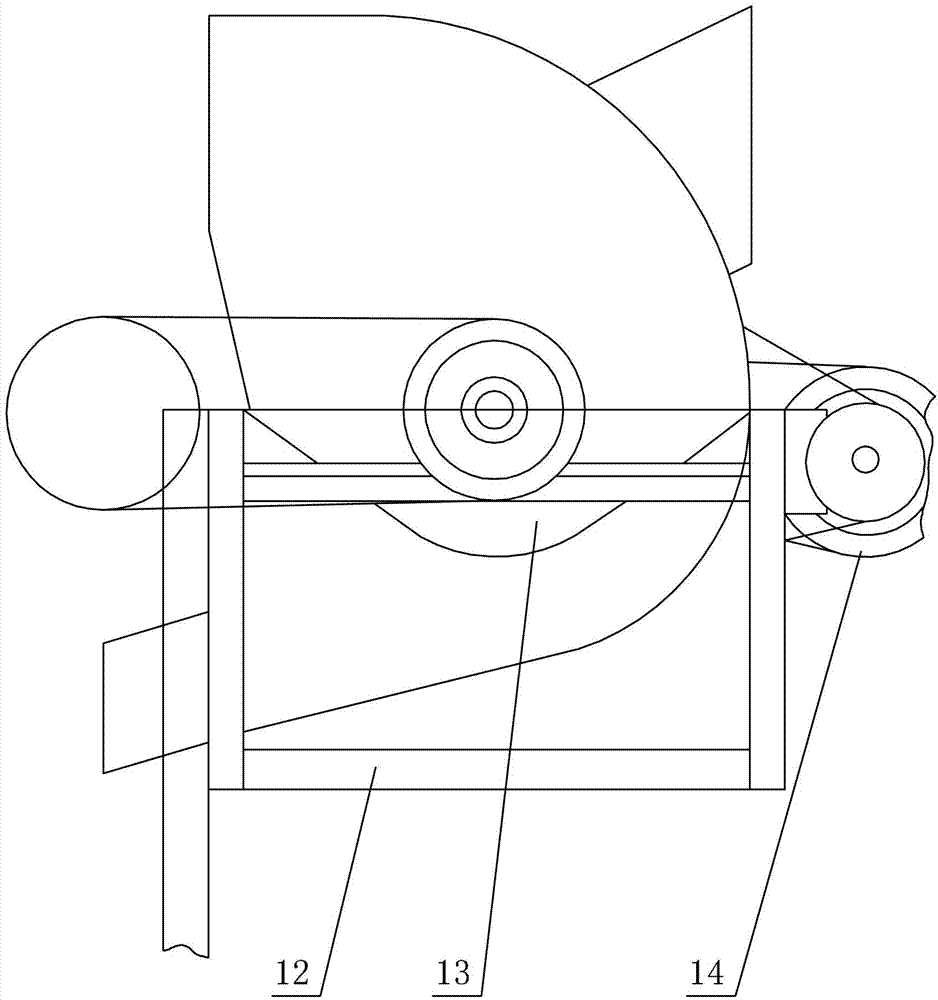

[0007] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment mode, a kind of corn grain mixed material secondary separation device described in this embodiment mode comprises left pulley 1, main shaft 2, outer helical blade 4, inner helical blade 5, core row impeller 7, right side pulley 11, separating Frame 12, intermediate shaft pulley 14, separation box housing 15, separation cylinder sprocket 16, intermediate shaft sprocket 18, separation cylinder 20, transmission chain 21, intermediate shaft assembly 23, transmission belt 24, feed box housing , the core box housing, two support assemblies, a plurality of positioning tugs 3 and a plurality of rubber blades 6, the feed box housing, the separation box housing 15, and the core box housing are installed on the separator in sequence from left to right on the frame 12, and the feed box shell, the separation box shell 15, and the core box shell are connected to each other, the separation cylinde...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 1 to Figure 4 To illustrate this embodiment, each support assembly of a secondary separation device for corn grain mixture in this embodiment includes a bearing seat 8 and a bearing 10 , and the bearing 10 is installed on the bearing seat 8 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 1 to Figure 4 To illustrate this embodiment, the feed box shell of the secondary separation device for corn grain mixture described in this embodiment is composed of an upper feed box shell 19 and a feed box lower shell 13 . Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com