Film bridge type igniter

A technology of igniter and thin film bridge, which is applied in ignition devices, attack equipment and other directions, can solve the problems affecting the miniaturization of igniter and the large volume of constant current source, so as to improve reliability and stability, enhance oxidation resistance, improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

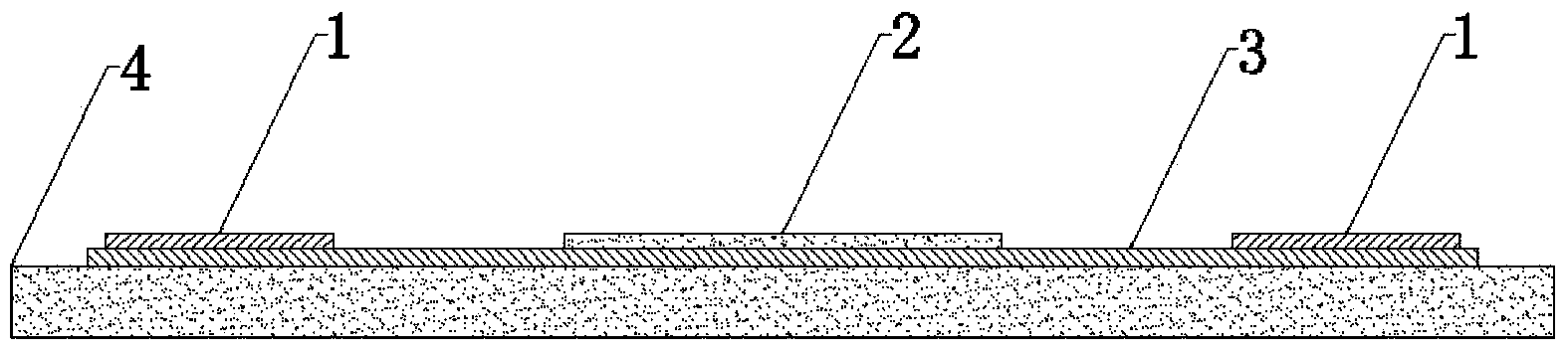

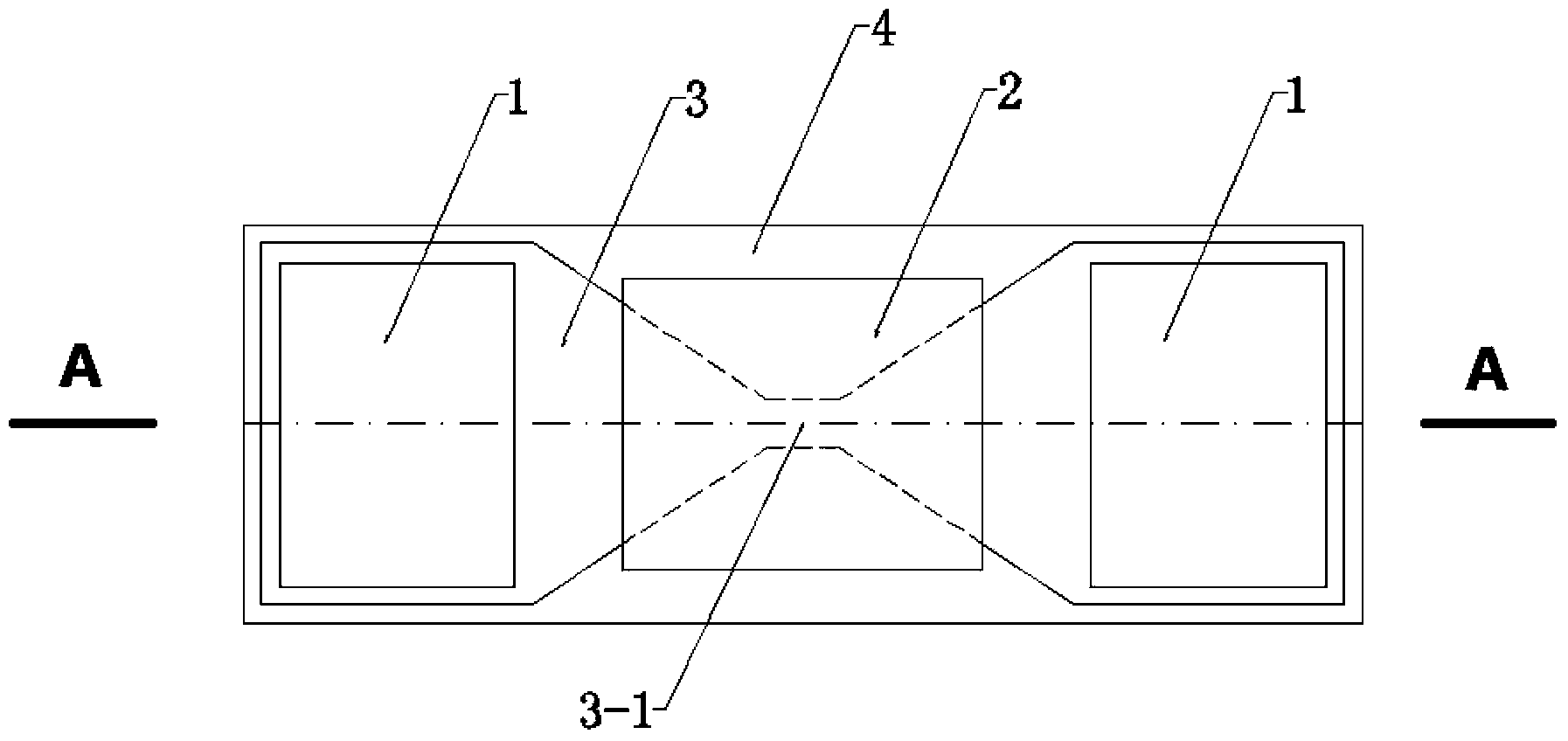

[0011] Embodiment 1: In this embodiment, an igniter of (length×width×thickness) 6mm×3mm×0.5mm is taken as an example, and the magnetron sputtering cavity adopts a conventional multilayer energetic thin film magnetron sputtering cavity; its production The method is:

[0012] Step 1. First, use acetone, alcohol, and deionized water to ultrasonically clean the alumina ceramic substrate 4 with a diameter of 76.2 mm (3 inches); then place the alumina ceramic substrate 4 on the back and vacuum it to 5×10 -4 In the magnetron sputtering chamber below Pa, under the conditions of 17sccm argon gas, 0.5sccm nitrogen gas, the pressure in the vacuum chamber rises to 0.6Pa, the DC power source current is 0.24A, and the voltage is 320V, the Ta target is ignited. And sputtering treatment for 50 minutes, until the thickness of TaN film deposited on the substrate is about 1 μm;

[0013] Step 2. Photolithographic TaN ignition membrane bridge:

[0014] 2.1. Coat photoresist on the substrate afte...

Embodiment 2

[0024] In this embodiment, the Ni / Al multilayer energetic film is used as an example: the processing of the substrate 4, the fabrication method of the TaN ignition membrane bridge and the thin film electrode 1 are all the same as in the embodiment 1 (i.e. steps 1-3);

[0025] Step 4. Place the substrate 4 provided with the TaN ignition membrane bridge 3 and the Al thin film electrode 1 in the magnetron sputtering cavity obtained in step 3, and vacuum 5×10 -4 Below Pa, pass argon 17sccm, oxygen 0.2sccm, adjust the pressure in the vacuum chamber to 0.6Pa, then adjust the current of the Al target DC power to 0.15A, and the voltage to 150V, so that the Al target can react with the TaN ignition film bridge 3 and the surface of the substrate 4 is sputtered for 8 minutes until the thickness of the aluminum oxide film is 100 nm, as an insulating layer;

[0026]Step 5. Using the background technology magnetron sputtering to Al as the bottom Ni / Al multilayer energetic film: on the alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com