Electrolytic aluminum waste material separating method and electric arc furnace

A separation method and electrolytic aluminum technology are applied in the field of electric arc furnace for electrolytic aluminum waste separation and electrolytic aluminum waste separation, which can solve the problems of long heating time and cumbersome separation method, and achieve the effects of simple operation, small particles and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Embodiment of electric arc furnace of the present invention

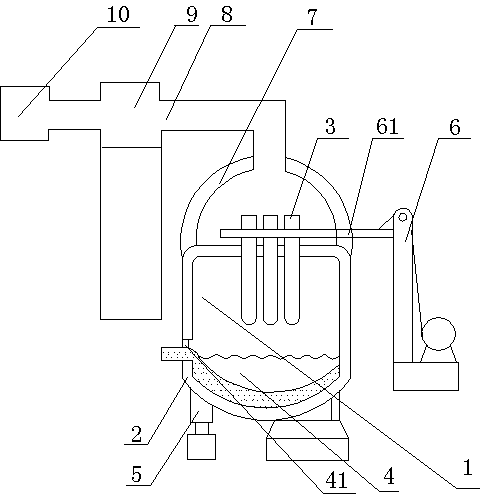

[0019] refer to figure 1 , the electric arc furnace embodiment comprises a furnace body 1, a furnace lining 2, a graphite electrode 3 is provided on the central upper side of the furnace body 1, a molten pool 4 with an outlet 41 is provided at the inner lower end of the furnace body 1, and a pouring tank 4 is provided on the lower side of the molten pool 4. Device 5, the outside of the furnace body 1 is provided with an electrode lifting mechanism 6 connected to the graphite electrode 3 through an electrode arm 61, and a gas collection device 7, an air extraction pipeline 8, a particle collection device 9, an air extractor 10, and a gas collection device 7 is located above the melting pool 4, the gas collection device 7 is connected to the air extractor 10 through the air extraction pipe 8, and the particle collection device 9 is installed in the middle of the air extraction pipe 8.

[0020] Th...

Embodiment 2

[0022] Embodiment 2: the method embodiment of the present invention

[0023] A kind of preferred embodiment of the present invention, electric arc furnace is as embodiment 1.

[0024] Put the electrolytic aluminum waste into the electric arc furnace. The electrolytic aluminum waste is one of fire eye carbon slag, anode ash or anode paste, cathode carbon block or cathode paste. Turn on the power supply and heat it at 3000℃~4000℃ through the electric arc. The carbon powder is separated from other components, and the other components become gas, thus obtaining high-purity carbon powder. Among them, other components become gases as fluoride, chloride, cyanide, sulfur, iron or silicon vapor.

[0025] Other components become gas, which is collected and cooled by the gas collection device 7 and the particle collection device 9, and finally extracted by the air extractor 10 for recovery.

Embodiment 3

[0026] Embodiment 3: the method embodiment of the present invention

[0027] Put the electrolytic aluminum waste into a high temperature resistant container. The electrolytic aluminum waste is one of fire eye carbon slag, anode ash or anode paste, cathode carbon block or cathode paste. The bottom of the container is grounded, and the welding torch of the electric welding machine clamps a piece Carbon rod, move the welding torch, keep a certain distance between the carbon rod and the upper surface of the electrolytic aluminum scrap in the container, let the arc generate, heat through the arc at 3000 ℃ ~ 4000 ℃, under the high temperature of the arc, other components in the electrolytic aluminum scrap , mainly fluoride, chloride, cyanide, sulfur, iron or silicon into gas, so as to be separated from the carbon powder in the electrolytic aluminum waste to obtain high-purity carbon powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com