Method of efficient extraction of aluminum, iron, and titanium in coal gangue

A technology of coal gangue and aluminum iron, applied in chemical instruments and methods, ferric sulfate, aluminum sulfate, etc., can solve the problems of single extraction product and high quality requirements of raw materials, achieve high silicon oxide content, ensure conversion rate, and be easy to form into balls Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

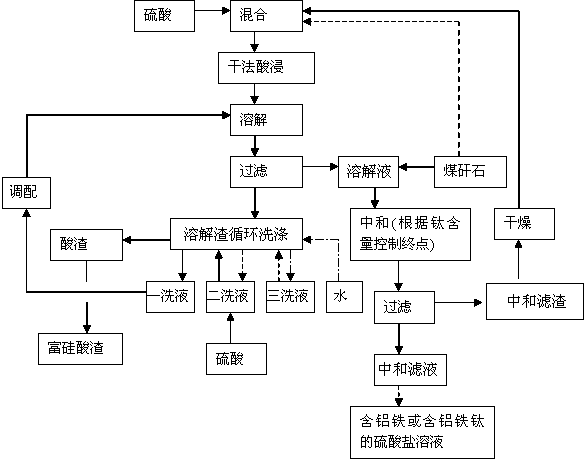

Method used

Image

Examples

Embodiment 1

[0046] (1) Take 10kg of dry coal gangue, powder it and pass it through an 80-mesh sieve, and the sieve residue is less than 5wt%, and set aside;

[0047] (2) Mix the coal gangue in step (1) with sulfuric acid of equal mass and concentration of 98wt% to form balls, then place the balls at 250°C for 1 hour to make clinker, and add 4 times the mass of clinker to the clinker , a sulfuric acid solution with a sulfuric acid concentration of 10wt%, reacted at 90°C for 1 hour to dissolve, and filtered to obtain a dry acid leaching solution; the dissolved residue was prepared with a sulfuric acid solution with a concentration of 10wt% that was equivalent to 4 times the mass of clinker and prepared with water. Washing, the solution after washing is marked as the first washing solution, which is used as the solution for the subsequent acid leaching of clinker, and then washed twice with water that is 4 times the quality of the clinker, and the solution after washing is marked as the secon...

Embodiment 2

[0053] (1) Take the coal gangue and pass it through an 80-mesh sieve after drying and grinding, and the sieve residue is less than 5wt%, and set aside;

[0054] (2) Take 108g of the dried sample of the neutralized filter residue in Example 1, and add 130g of sulfuric acid with a concentration of 98% to form balls based on the acid residue ratio of 1.2, place them in a box furnace, and react at 250°C for 1 hour to obtain cooked After the clinker is taken out, add 324g of the last primary washing solution with a sulfuric acid concentration of 7.5wt%, and react in a three-necked flask for 1 hour at a reaction temperature of 90°C. 324g of 5wt% dilute acid solution is washed for the first time, and 324g of the previous three washing liquids are taken for the second washing, and finally the third washing is carried out with 324g of clear water;

[0055] Through the analysis of acid leaching dissolved slag, based on the percentage of valuable elements in neutralized fresh coal gangue...

Embodiment 3

[0060] (1) Take the coal gangue and pass it through an 80-mesh sieve after drying and grinding, and the sieve residue is less than 5wt%, and set aside;

[0061] (2) Take 130g of the dried sample of the neutralized filter residue in Example 2, and add 130g of acid to mix it with acid residue according to 1.0, put it in a box furnace, and react at 250°C for 1 hour to obtain clinker. After taking out the clinker, add sulfuric acid Concentration is 520g of the last first washing solution of 8wt%, reacted in a three-necked flask for 1h, the reaction temperature was 85°C, after the reaction was finished, it was filtered, and the dissolved residue was prepared with 390g of 10wt% dilute acid solution prepared by the last second washing solution for the first For the first washing, take 390g of the previous third washing solution for the second washing, and finally use 390g of clear water for the third washing;

[0062] Through the analysis of acid leaching dissolved slag, based on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com