Aqueous dispersion crosslinkable random fluoropolymer and constructed super-amphiphobic coat through aqueous dispersion crosslinkable random fluoropolymer

An amphiphilic polymer and cross-linking technology, which can be used in coatings, plant fibers, textiles, and papermaking, can solve the problems of high synthesis cost of block polymers, unsuitability for large-scale industrialization, and complex processes , to achieve the effects of cost reduction and industrialization, wide application, simple synthesis method and synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

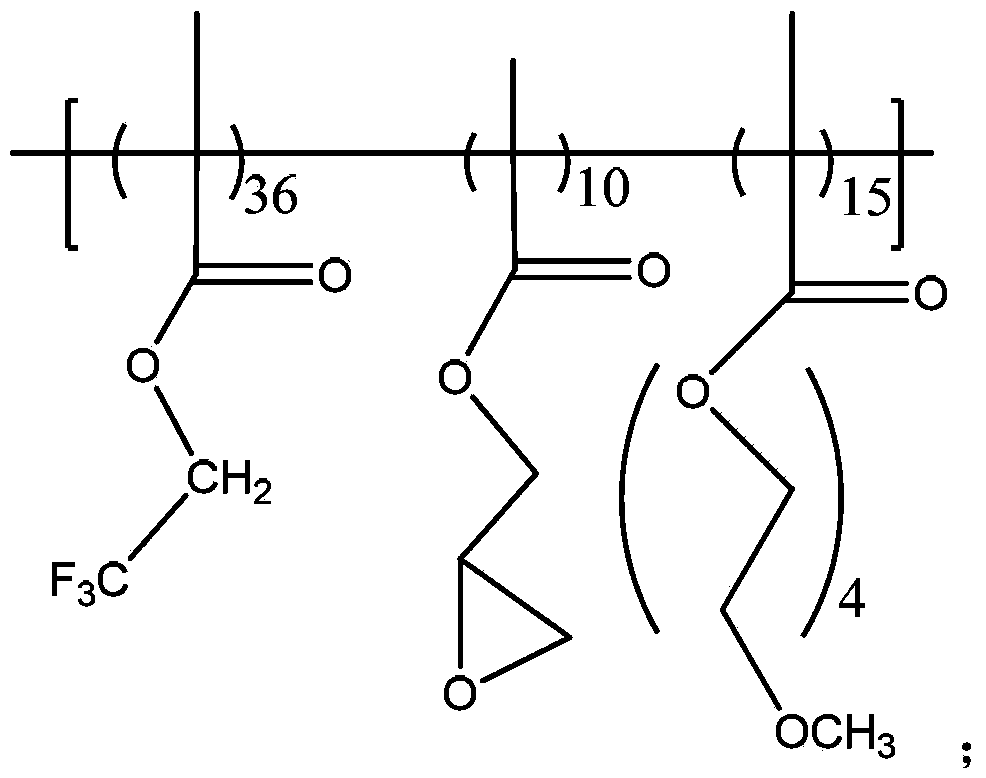

[0030] (1) Use free radical polymerization to synthesize water-dispersible crosslinkable random fluoropolymer with the following structure: take 80mL cyclohexanone, 5.8g trifluoroethyl methacrylate, 1.2g glycidyl methacrylate, 2.3g polyethylene glycol methyl methacrylate (n=4) and 0.02g azobisisobutyronitrile were added to a 200ml reaction flask. After deoxygenation, it was placed in a flask at 80°C and stirred for 3.5 hours. After that, the reaction was terminated. Then it was concentrated to 20ml with a rotary evaporator, then precipitated from n-hexane, and dried in vacuum to obtain a water-dispersible crosslinkable random fluoropolymer with the following structure, with a mass of 6.2g.

[0031]

[0032] (2) A method for constructing super-biphobic coating with water-dispersible crosslinkable fluoropolymer:

[0033] Dissolve the water-dispersible crosslinkable random fluoropolymer obtained in the above step (1) in a solvent, then add a catalyst and inorganic nanoparticles to fo...

Embodiment 2

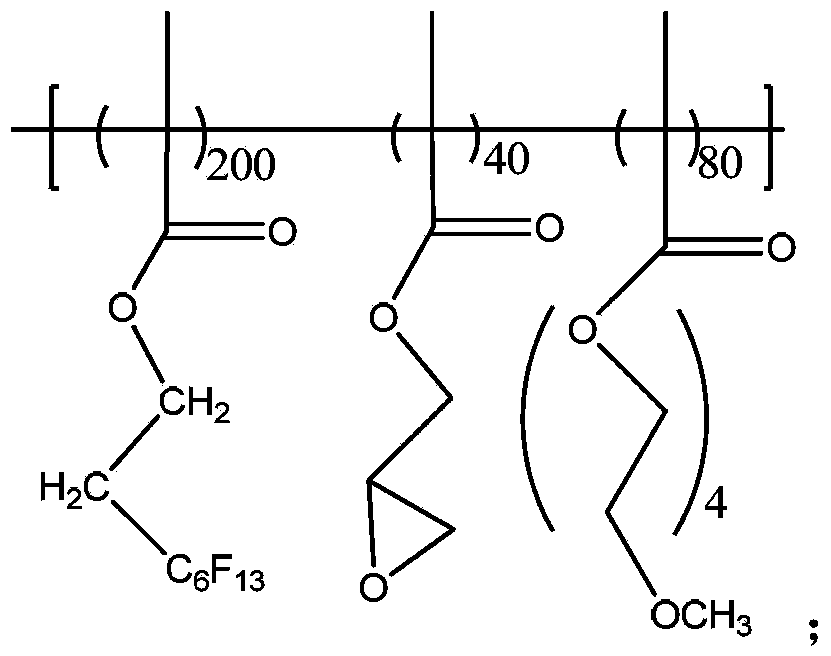

[0036] (1) Use free radical polymerization to synthesize a water-dispersible crosslinkable random fluoropolymer with the following structure: take 100mL dioxane, 9.8g tridecafluorooctyl methacrylate, 4.2g glycidyl methacrylate Ether, 4.3g polyethylene glycol methyl methacrylate (n=4), 0.08g azobisisobutyronitrile were added to a 200ml reaction flask, after deoxygenation, put it in a flask at 70°C and stir to react After 5.5 hours, the reaction was terminated. Then it was concentrated to 20ml with a rotary evaporator, and then precipitated from anhydrous ether, and then dried under vacuum to obtain a water-dispersible crosslinkable random fluoropolymer with the following structure, with a mass of 12.2g.

[0037]

[0038] (2) A method for constructing super-biphobic coating with water-dispersible crosslinkable fluoropolymer:

[0039] Dissolve the water-dispersible cross-linkable random fluoropolymer obtained in the above step (1) in a solvent, and then add catalyst and inorganic nan...

Embodiment 3

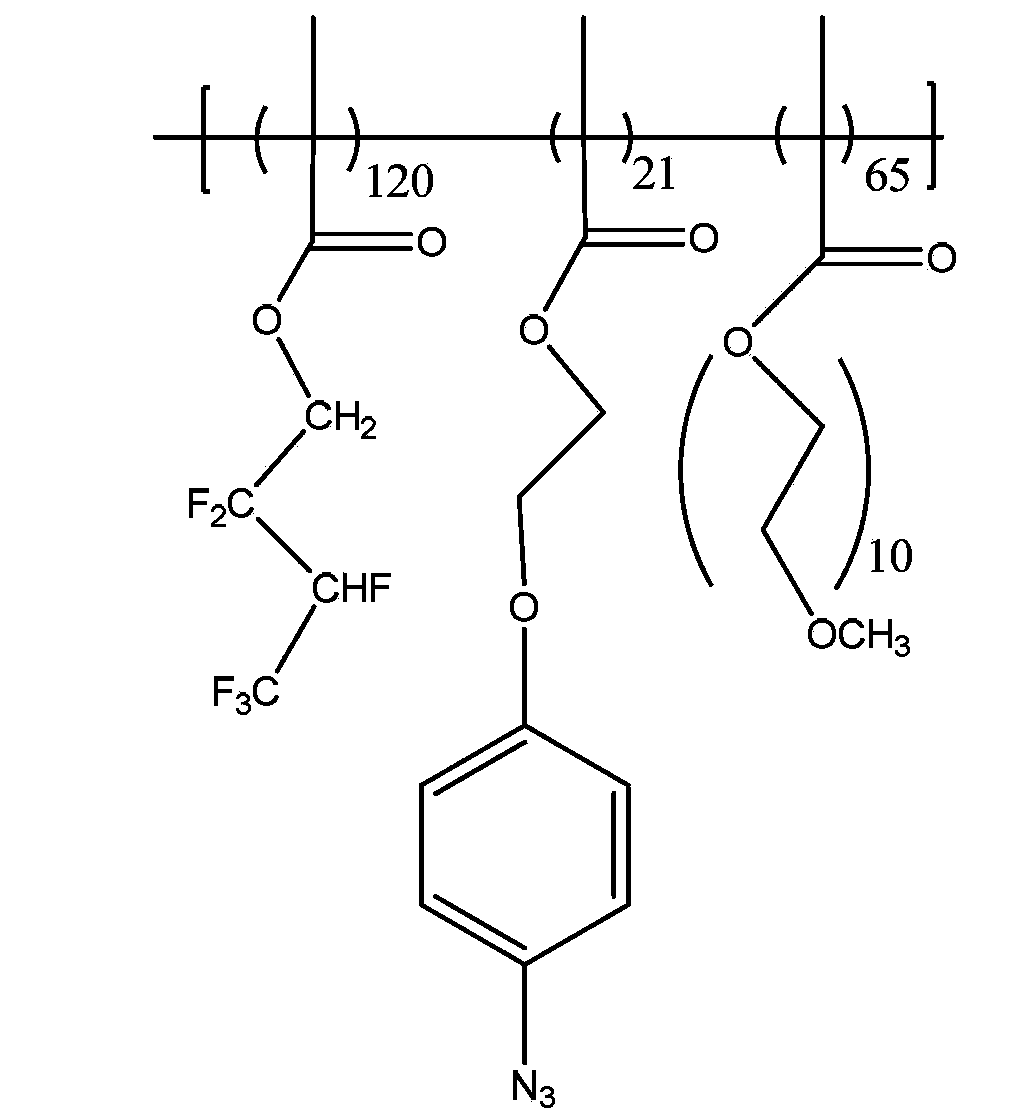

[0043] (1) Use free radical polymerization to synthesize a water-dispersible crosslinkable random fluoropolymer with the following structure: take 100mL dioxane, 6.7g hexafluorobutyl methacrylate, 3.2g methacrylic acid-4-4 Azide phenyl ester (the synthesis method, reference: Li Guang, synthesis of new azide monomers, polymer reaction and polymer application research, 2010 PhD thesis of University of Science and Technology of China), 3.3g polyethylene glycol methyl Methyl methacrylate (n=10), 0.02g benzoyl peroxide was added to a 200ml reaction flask, after deoxygenation, it was placed in a flask at 70°C, and the reaction was terminated after stirring for 5.5 hours. Then it was concentrated to 20ml with a rotary evaporator, and then precipitated from anhydrous ether, and then dried under vacuum to obtain a water-dispersible crosslinkable random fluoropolymer with the following structure, with a mass of 10.2g.

[0044]

[0045] (2) A method for constructing super-biphobic coating w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com